To achieve maximum economic effect and energy efficiency in the operation of the heating system, shutoff valves for heating should be installed in its circuit. It has a high quality of execution and can be used in the arrangement of boiler houses for private houses, multi-apartment buildings and centralized heat supply organizations.

Purpose of locking plumbing

In heat generation systems, valves of the locking type act as a regulator of the flow and movement of the coolant, and also allows you to open the heating circuit. The heating process in this case becomes controlled, increasing its rationality and efficiency.

The shut-off valve is most often mounted on the span of the line where the battery is piped. This technique allows you to adjust the heating of the radiator and facilitates the task of maintenance and repair of the heater without the need to turn off the entire heat circuit.

Types of shut-off elements

Standard heating on any boiler equipment where water or antifreeze is used as the heat carrier has locking plumbing in the structure, which is subject to the following classification:

- Shut-off elements - taps designed only to shut off the flow.

- Shut-off and regulating elements are specialized valves with thermal heads and mechanical design.

- Mixing and regulating elements - three-way valves and similar equipment.

All other components of the heat circuit - filters, air vents, safety valves and measuring instruments - are not shut-off and control valves for heating.

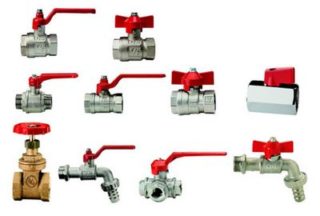

Ball valves

Ball valves made of brass are used in heating for convenient connection of thermal batteries to the pipeline. There are simple and complex designs of this kind. In the latter case, the structure of the device has an air release mechanism and a threaded channel for installing a pressure gauge.

The main element of this type of valve is a full bore ball, which is compressed by special o-rings made of polypropylene. The latter serve as a damper between the working surface of the sphere and the body of the product.

Locking valves

In order to be able to connect or disconnect a separate radiator from the circuit (due to preventive maintenance or replacing the heater) and not drain all the water, each battery is equipped with a shut-off valve. On the market you can find angular and straight products of this sample made of brass with nickel plating on top.

Butterfly Valves

The working part of valves on heating radiators of this type has the form of a disk. If you look at the device in section, the shutter inside the product can be located at a right or another angle to the channel of movement of the coolant and has the ability to turn around its axis.

Valves of this design are often used not only in heat supply, but also for regulating the flow of industrial or drinking water.

Backstop valve

The non-return valve in the heating system controls the movement of the coolant in a given direction. Therefore, such devices are installed in the heat supply line immediately after the circulation pump.To counter the aggressive environment, the body of the product is made of brass, the inner stem with a damper is made of plastic, and the spring is made of stainless steel.

It is permissible to use the device at a temperature of the working medium up to 120 degrees Celsius.

- Stopcock

- Slewing crane

- Check valve

Flanges

Connection elements with which you can make a detachable rigid docking of steel water pipes and other equipment to them. Flanges are attached to the pipes with a weld. The shape of the product is in the form of a ring or disk of different diameters and thicknesses, in which mounting holes are drilled in a circle. There are flanges with a collar or just flat. Most often, plumbing is made of stainless steel or steel resistant to corrosion.

Fitting

These are various elements that provide for the interconnection of individual pipes and other components of the boiler installation. Fittings are:

- couplings of various diameters with internal and external threads;

- corners with a change in fluid flow by 90 or 45 degrees;

- tees with a lateral branch of a stream under 90 or 45 degrees;

- crosses;

- plugs with internal or external thread to interrupt the pipe channel or exhaust fitting.

Elements can be made of steel, stainless steel, bronze and its alloys, plastic.

Gate valves

These are overlapping devices intended primarily for trunk pipelines. The design assumes the presence of a rotary lever inside the disk shutter. A distinctive feature of the valve is its low resistance to hydraulic flow.

- Gate valves

- Fitting

Application of shutoff and control valves

Each type of product can effectively perform only the task for which it is designed in accordance with the category of use:

- Conventional cranes are advisable to install in order to block the flow during the repair work or disconnect the batteries.

- Valves with temperature regulators are applicable only to automatically reduce, increase the flow of coolant in accordance with the set temperature;

- Three-way valves or taps are designed to redistribute the flow in the presence of indirect heating boilers and similar installations.

The use of locking plumbing for other purposes is fraught with emergency situations and ineffective operation of heat-generating equipment.

In heating systems, ball valves are usually installed at the beginning of the supply and return of the thermal circuit, on the batteries themselves with an upper and lower connection, an adjustment valve with a thermal head is mounted at the top, and a shut-off device is installed at the bottom. Check valves are usually installed in complex structures with two or more circuits immediately after the circulation pumps, in order to prevent reverse movement of the coolant.

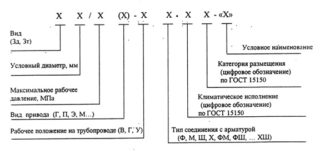

Product labeling

The marking of specialized valves has a code of the form - ХХ ХХ Х ХХ ХХ, where the following data are indicated (from left to right):

- Type of plumbing - indicated by a number.

- Case material - indicated by a letter.

- Type of manual control drive - indicated by a number (if there is no drive, marking is omitted).

- Serial number.

- The material for the manufacture of seal rings.

The encoding can be decrypted according to special tables.

Well-known manufacturers

Among the global manufacturers that produce high-quality sanitary ware elements, one can distinguish:

- Valpres - Italian ball valves made of stainless steel, cast iron and carbon steel.

- OVETROP - German control and locking plumbing.

- SANHA - brass and copper fittings from Germany.

- HOGFORS - Finnish valves.

Among the domestic manufacturer, the company Armafit has established itself.