The current standards regarding the thermal protection of pipelines prescribe the use of special insulators made of insulation materials. Pipe insulation works are labor-intensive procedures; the protective materials themselves do not differ in long service life. It was possible to solve this problem after insulating type cylinders for mineral wool pipes appeared on the market for construction products.

What are heat-insulating cylinders

Heat-insulating cylinders are special structural elements used for warming pipelines in heat supply systems and other highways. They have a cylindrical shape and are used as the outer shell of pipes, which reduces heat loss. There are several varieties of cylindrical products, which are subject to the following requirements:

- low thermal conductivity;

- high level of sound insulation;

- resistance to climatic influences;

- chemical and frost resistance.

Basalt cylinders for pipes are characterized by resistance to moisture and low susceptibility to harmful fumes.

Materials for pipe insulation

In the manufacture of protective cylindrical clips worn directly on the pipes, the following thermal insulation materials are used:

- mineral (basalt) wool;

- foam glass;

- foamed polyethylene (polyurethane) and similar insulators.

- Foamed polyethylene

- Basalt wool

- Foam glass

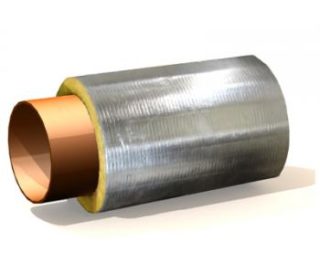

The most common in building cylinders are mineral wool heat insulators coated with aluminum foil. The metallized shell of such a product reduces heat loss, while increasing the level of protection against damaging effects. Another useful feature of lined stone wool cylinders is the ability to protect pipe lines from freezing.

In addition to the options considered, polyurethane foam (PUF) shells, which are among the best examples of external heat insulators, are widely used.

The advantages of these products include:

- light weight and ease of installation;

- high rate of thermal insulation;

- durability - their service life is at least 30 years;

- mechanical strength;

- the possibility of reuse and quick access to protected pipes;

- resistance to sudden changes in temperature.

In addition, the protective shells have good waterproofing properties.

Cylinder characteristics

Mineral wool cylinders for pipes have technical specifications similar to those of stone wool itself. The main of these parameters:

- Density - 150-200 kg / m³.

- The thermal conductivity of the material is 0.037-0.046 W / m * K.

- Combustibility group - NG, G1 (with protection from aluminum foil).

- Operating temperature range - from -190 to +700 degrees.

- Compressive strength - up to 70 kPa.

- The vapor permeability of the heat insulator is 0.25 mg / m² * h * Pa.

- The tensile strength of separation of individual layers is 15 kPa.

- The ultimate tensile strength is 15 kPa.

- The elasticity of the insulation material is 85%.

It is most convenient to get acquainted with the technical characteristics of these products during a comparative analysis of the fields of application and after taking into account the specifics of installation.

Comparative assessment

Not all types of insulation materials from which protective products are made are able to withstand significant loads. Mineral wool thermal insulating cylinders, for example, turned out to be the most vulnerable in this part. After unacceptable compression, they begin to absorb moisture and quickly deteriorate - they lose their protective properties.

In this case, preference is given to products made of foamed polyethylene, the resistance to compression of which is slightly higher. On the other hand, due to the fragility of the material, the elements made on its basis are more suitable for insulation of pipes of small diameter, laid only indoors.

Styrofoam cylinders are more effective at thermal protection, and also are steady against moisture and durable. However, they are not protected from rodents and are substances that support combustion. In addition, they do not “hold” high temperatures and are not suitable for the protective insulation of FGP pipes.

The most universal in application are products made of polyurethane foam, which have long operational periods and are distinguished by their incombustibility. They have a low coefficient of thermal conductivity and good sound absorption. Shells made on the basis of PPU are not exposed to the threat of destruction by rodents.

Mounting Features

Regardless of which type of cylinder is selected, the following rules for installing protective products will need to be observed:

- For reliable sealing of the joint zone, a special adhesive tape is required. It is used for internal thermal insulation of pipe routes.

- With open pipe laying, a special adhesive-based foil tape is used.

- Heat insulation and pouring of PUF of street pipes are carried out only in dry weather.

- Installation of protective cylinders on damp surfaces is not allowed, as this will degrade the quality of thermal insulation.

Mineral wool cylinders are worn on pipes or sections of pipelines only after careful preparation of surfaces, which guarantees a reliable fit of the material and a higher level of protection. When warming, metal pipes are pre-painted. For these purposes, it is recommended to use special priming (powder) coloring compositions.

Fields of application

According to current standards, it is allowed to use cylindrical protection:

- in private and collective housing construction;

- in heating mains of multi-storey buildings and other urban facilities;

- in piping systems mounted at production sites;

- on the main lines along which coolants and other easily freezing liquids are pumped.

Most samples of cylindrical protective products are suitable for the insulation of almost all of the above structures. At the same time, cylinders based on mineral (basalt) cotton wool and their analogues are particularly versatile. They are allowed to insulate the following household and industrial facilities:

- open and underground heat routes;

- piping systems for pumping liquid heated to very high temperatures (up to 600 ° C);

- water and sewer lines with the aim of protecting them from freezing.

Particularly popular are Rockwool cylinders, lined with aluminum foil, as well as PPU shells. With their help, most of the pipe routes that make up the heating systems and individual water pipes are insulated.

Popular manufacturers

The most famous firms and companies producing high-quality heat-insulating cylinders are Rockwool, Knauf and ISOVER.Despite the relatively high declared price, Rockwool cylinders, for example, have for many years been leaders in the market of insulation materials. Most of the samples produced by these manufacturers have the following design features:

- they provide for special L-shaped locking mechanisms that guarantee the protection of pipelines from cold bridges;

- differ in a neat appearance corresponding to the shape of the pipe to be insulated;

- The supplied kit includes a full range of additional elements, including tees, intersections and angular bends;

- the installation procedure for the cylinders is very simple and does not require highly qualified performer.

Given these features, anyone can insulate the home pipeline with Rockwool cylinders independently, using the instructions provided with the kit instructions.

Thermal insulation products from well-known manufacturers, as a rule, consist of 2 cylinder halves, which, when assembled, are fastened with a special binder. The latter is completely safe for the operator, since even with strong heating it does not emit chemical components (phenol and formaldehyde). Among the models offered by manufacturers, the Rockwool 100 products stand out, which are in great demand among specialists and home craftsmen.

Pipe insulation Rockwool is made in the form of regular cylinders with an inner diameter of 18 to 273 mm. The thickness of their walls takes the following values: 20, 25, 30, 40, 50, 60, 70, 80 and 100 millimeters. If insulation blanks are required for a larger diameter pipeline, the product line includes Rockwool ProRox cylinders (Holland). The construction organization in need of such samples will have to order them separately, indicating the required size. In the same way, a situation is solved when builders required products of non-standard thickness. Such cases are especially common at oil and gas facilities.

Some Rockwool cylinder samples are coated with aluminum foil. Products reinforced in this way usually have the ROCKWOOL logo. Thanks to this, it is possible to determine their affiliation and not confuse it with samples similar to the original. All products are delivered in dense synthetic packaging, in which several products are packed.