The heating of a residential building with gas heating the ascending air currents is characterized by low fuel consumption and affordability. To implement this method, a gas heating converter is required. Before purchasing it, you should understand the principle of operation and the rules for choosing the right sample, suitable for specific operating conditions.

Device and principle of operation

To understand how a gas heating convector works, it is advisable to familiarize yourself with its device. The structure of this device includes the following main components:

- gas fuel combustion chamber;

- a heat exchanger that is part of the chamber;

- burner and ignitor installed in it;

- Control block;

- thermostat;

- device case.

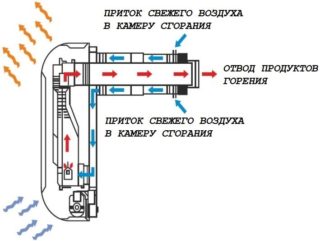

For stationary models, you will need to make two holes in the wall, through one of which air is taken from the streets, and through the second, combustion products are removed. Most of the samples on the market are non-volatile and completely autonomous, but there are products that require electrical power. The latest models are good because they manage to implement the automatic mode of maintaining the flame in the burner.

The principle of operation of the convector is as follows:

- the process begins with the conversion of gas energy into its thermal equivalent;

- heat generated during combustion heats the heat exchanger located in the area of air intake from the street;

- when heated, the latter rushes up and gives off heat to the surrounding space;

- then the cooled masses leave the heat exchanger through special perforations.

Products of combustion of gas fuel are discharged through the outlet pipe (chimney) directly to the street.

Advantages and disadvantages

Indisputable advantages of gas convectors for heating a house include:

- the ability to do without electricity;

- the speed of heating the surrounding space (in comparison with a heating boiler with radiators);

- profitability;

- minimum care and maintenance requirements;

- attractive appearance.

The disadvantages of these devices are the impossibility of a full replacement of the gas boiler and the need to make holes in the wall that violate its integrity and design.

Specifications

Technical characteristics of gas convectors are represented by the following operating parameters:

- thermal power (from 3 to 9 kW);

- type of fuel used (liquefied or main gas);

- device placement method (floor or wall);

- the presence of a gas exhaust system (chimney).

All of them are considered in detail when choosing the right model of a heating unit.

Rules for choosing a gas convector

When choosing a gas convector, you need to proceed from the requirements for this device and its characteristics. First of all, the following parameters are taken into account:

- thermal power and allowable area of heated spaces;

- type of combustion chamber;

- type of fuel (gas) used;

- installation option (wall or floor).

To determine the required power, proceed from the practical derived ratio, according to which 1 kW of thermal energy is required for effective heating of every 10 m2 of living space.Experts recommend choosing this indicator with a small margin. To warm up a room with an area of 25 m2, according to the set-off ratio, a device for 2.5 kW is required. But for greater certainty, it is better to buy a device with a power rating of 3 kW.

The type of combustion chamber (open or closed) is selected based on the user's preferences. Most convectors are equipped with a chamber of the second type, the main advantage of which is the absence of unpleasant odors. Models equipped with an open burner have the following disadvantages:

- when working, a lot of oxygen is burned;

- part of the combustion products enters the living room;

- when arranging systems with an open chamber, a chimney with an exit through the roof will be required.

Before choosing a convector, it is important to consider the type of fuel used (liquefied or ordinary natural gas). In the first case, the instrument kit includes additional equipment (jet and gear). Fuel management in these products is automatic.

Wall convectors are more convenient in that they do not need to update the cylinder, the capacity of which is enough to heat large areas. Their floor counterparts are more versatile, but it is forbidden to use them in apartment buildings. When using gas heating batteries in the country or in a private house, you will have to provide a separate metal cabinet for the cylinder, located outside the building.

Heat exchanger features

A feature of the main component of the convector (heat exchanger) is the type of material from which it is made. The question of his choice is considered simultaneously with the design of the combustion chamber, since both of these elements are parts of the same assembly. Both are made of heat-resistant steel or cast iron.

Products of the first type are much lighter and cheaper, but they have one drawback. The relatively thin walls of steel chambers burn out over time (at least the probability of this is high). In contrast, models with cast-iron heat exchangers have a long service life.

Smoke removal

Removal of the products of combustion of gas fuel is organized naturally (due to pressure drops at different points) or forced way. In the second case, a fan of sufficient power is installed in the channel of their output. The advantages of natural tap samples include their low cost and simplicity of design. Models with forced smoke removal have a more complex electrical circuit and for this reason are much more expensive.

Scope of application

Gas-fired air heating is an optimal solution that allows heating the interior spaces of a private house at low cost. In terms of efficiency, it is comparable to stove and water heating, but it is much cheaper. In addition to residential buildings, gas convectors are used in greenhouses, poultry farms and livestock complexes. Most often they are in demand in those conditions where it is not possible to install a boiler with a system of water radiators. This situation is typical for the following places:

- basement habitable premises;

- underground garages;

- basement floors of buildings.

The mobile version of the liquefied gas convector is used when necessary to heat small objects such as country houses, retail outlets and private garages.

Overview of convectors from various manufacturers

An overview of the best models of convectors, safe from an operational point of view, will help to choose the right sample of gas equipment.One of its best representatives is the ATON Vektor 3, which is a non-volatile floor-mounted device. Due to its compactness and mobility, this sample is ideal for heating small spaces. With its help, it is possible to automatically maintain the desired temperature in the range from 13 to 18 ° C. The closed combustion chamber and heat exchanger of this product are made of steel. Power convector weighing 22 kg is 3 kW.

The gas heater from the manufacturer Hosseven HBS is represented by a floor convector equipped with an open combustion chamber. The unit is able to operate on main and liquefied gas. The scope of supply includes a telescopic gas outlet. The convector heat exchanger and the combustion chamber are made of steel. The thermal power of the unit is 9 kW, and the average gas flow rate is 0.73-0.9 m³ / h.

Hosseven HP Convector is a gas battery with a modern and stylish design, powered by natural gas. If desired, the mobile unit can be connected to a cylinder with liquefied fuel. The device is equipped with a closed-type combustion chamber made of steel. The thermal power of this product is 6.9 kW, and the average gas flow rate is 0.7-84 m³ / h.