An electric boiler for heating large rooms is used when the area is not connected to a gas pipe. In this case, there are two options: solid fuel, for which you need to harvest raw materials or an electrician. Solid fuel units are less economical and require constant attention. Compared to electric, they are less profitable. An electric boiler can be used as an additional source of heat in the winter, as the gas flow rate by all residents is sometimes so high that it is impossible to achieve the required power and the room cools down.

The advantages of electric boilers

In comparison with gas or other types of heating boilers, electric ones have advantages:

- Silent operation, as the heating elements turn on imperceptibly.

- Can be left unattended, just like gas. The boiler can turn itself off only in the event of a power outage. The operation of the equipment is fully automated.

- Low cost of equipment, as well as installation and maintenance.

- Fewer installation problems, as the electric boiler does not need installation documents.

- The small size of the unit, but at the same time, the power develops high.

- Environmentally friendly - there are no chimneys or residues that require disposal or disposal. It can be connected in any room.

In regions where the cost of electricity is high, it is unprofitable to install electrical equipment for heating a private house. Gas in this case will be cheaper for utility bills.

Boiler Models

To choose a suitable electric boiler for heating a private house, you need to know what characteristics they differ in, as well as what purpose the customer is pursuing: is he going to completely switch to electric heating or install equipment as a fallback.

What parameters distinguish electric boilers:

- power;

- design features;

- sizes

- the form;

- cost of products;

- manufacturer - domestic or foreign.

By the type of heating element, induction, heating elements and electrode electric boilers are distinguished.

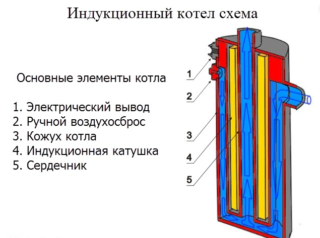

Induction

The principle of operation of an induction boiler is similar to a transformer: there is a primary and secondary winding, as well as a core, through the pipes of which water flows. When turned on, the primary winding converts the current into a magnetic field, which acts on the secondary. In this case, the core heats up and transfers the energy of the liquid.

The principle of operation of an induction boiler is similar to a transformer: there is a primary and secondary winding, as well as a core, through the pipes of which water flows. When turned on, the primary winding converts the current into a magnetic field, which acts on the secondary. In this case, the core heats up and transfers the energy of the liquid.

The advantages of an induction electric boiler for heating:

- high protection against a scum;

- high efficiency - about 98%;

- profitability - with low energy consumption, the boiler generates a lot of heat;

- fire safety;

- resistance to temperature extremes.

In the design of the unit there are no rapidly wearing mechanisms, so they can work up to 30 years. Various liquids are used as a heat carrier - distilled water, oil, and refined petroleum products.

The disadvantage of electric boilers is the high weight and high cost. The smallest boiler can weigh more than 20 kg.

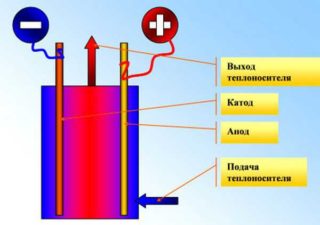

Electrode

The principle of operation of ion boilers is the potential difference on the electrodes that are in the heat exchanger. A special liquid is used, with the addition of electrolytes, so that it enhances the potential and heats up faster. A small size ionization chamber is used to heat the water.

The advantage of the electrode boiler is its high power with low power consumption, for example, in comparison with the heating elements, 2 times. The equipment heats up quickly, which allows you to reach the desired temperature in a large room in half an hour.

The equipment is not sensitive to voltage drops, so it does not turn off. When the coolant leaks, the boiler turns off, as the current potential at the electrodes decreases. Otherwise, there is nothing to break in these models, therefore the boilers serve for a long time.

There is one drawback: you need to buy a special liquid, since the boiler will not work on ordinary water.

Using heaters

These models work on the principle of an electric kettle, where the heating coil is placed in a shell made of stainless steel or another metal. Several heaters can be located and operate in the heat exchanger at the same time.

These models work on the principle of an electric kettle, where the heating coil is placed in a shell made of stainless steel or another metal. Several heaters can be located and operate in the heat exchanger at the same time.

The tenov model has the advantage of minimizing the risk of a short circuit, and it is protected by a temperature controller that prevents the equipment from overheating.

The disadvantage of shadow boilers is the formation of scale. To extend the life of the boiler and reduce the risk of breakage, it is recommended to use distilled water for pouring.

Specifications

The technical characteristics of an electric device include power, the number of circuits, efficiency, connection method, material for manufacturing parts and a housing, as well as the type of automation and device dimensions.

Unit power

The power required for space heating is calculated roughly: 1 kW per 10 square meters. But when choosing a power, other characteristics are taken into account: wall thickness, ceiling height, heat loss due to an insulated ceiling or old wooden windows, the number of cameras in double-glazed windows on metal-plastic windows, the total area of windows in a house or apartment. You should also consider the climate in a particular region.

The power required for space heating is calculated roughly: 1 kW per 10 square meters. But when choosing a power, other characteristics are taken into account: wall thickness, ceiling height, heat loss due to an insulated ceiling or old wooden windows, the number of cameras in double-glazed windows on metal-plastic windows, the total area of windows in a house or apartment. You should also consider the climate in a particular region.

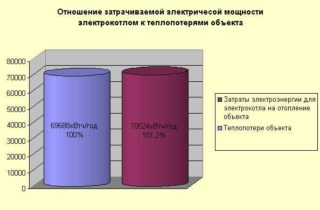

To calculate how much electricity is consumed during the operation of the boiler, there is no exact formula. Here you need to understand that electrical equipment consumes as much energy as it leaves the room in the cold season.

It is advantageous to buy the equipment that has a representative office in the region in order to carry out high-quality repairs if necessary. Domestic electric boilers are made with high quality and are cheaper, but in a certain region there may not be a craftsman familiar with the design of models.

On boilers, the type of power adjustment may vary - smooth or stepwise. If the unit has additional heating power, the type of adjustment will be stepwise. Usually the main element provides half of the total power, the other two - 25% each. If necessary, you can disable additional items.

Efficiency of electric boilers

It is useless to choose an electric boiler for efficiency, since all models have a high rate - from 96 to 98%. Energy conversion, not its generation, is the principle of all heating equipment of this type.

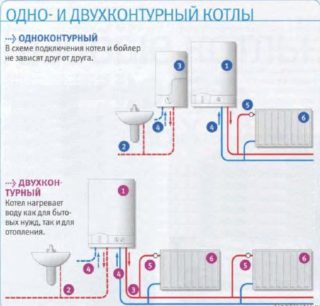

Number of circuits

If the boiler has one circuit, it will only work on heating the room. In this case, it is recommended to take care of the method of heating the water. Bypass equipment is able to switch from space heating to water heating for users.

If the boiler has one circuit, it will only work on heating the room. In this case, it is recommended to take care of the method of heating the water. Bypass equipment is able to switch from space heating to water heating for users.

Connection method

You can choose a single-phase or three-phase boiler - 220 and 380V, respectively. It depends on what type of wiring is available in the house. The power of a single-phase unit will be less, three-phase more.

Materials

It matters for the service life of which materials the internal parts and the housing are made. The metal frame is able to withstand shock loading, so it is more profitable to buy it. Basically, all manufacturers produce boilers in a metal case.

Type of automation

In electric boilers to control the air temperature in the room, one of two types of automation is installed: electronic or mechanical.In the first case, the circuit is opened when the temperature reaches the desired level. In the second there is a remote sensor that monitors the temperature regime. When it is reached, the device transmits a signal to the control unit and it turns off the unit.

In electric boilers to control the air temperature in the room, one of two types of automation is installed: electronic or mechanical.In the first case, the circuit is opened when the temperature reaches the desired level. In the second there is a remote sensor that monitors the temperature regime. When it is reached, the device transmits a signal to the control unit and it turns off the unit.

When the temperature drops to a certain level, the equipment turns on again without human intervention. If you set the lower and upper temperature thresholds in the minimum range, the boiler will turn on and off more often. This affects the duration of its operation in the case of a heating element.

Equipment

There is a basic configuration of electric boilers and additional options. The second option is more expensive, but it may turn out that subsequent installation of options will increase the cost of the device several times, including the work of the wizard. Additional options include:

- automatic water discharge if the equipment is not used at low temperatures;

- system pressure control;

- centrifugal pump to enhance fluid circulation through pipes;

- filter for water purification;

- remote sensor for temperature control in distant rooms.

Sometimes it is necessary to use an expansion tank, so it is bought separately, since it is not included in the basic equipment of the device.

Installation and connection

There are no special rules for installing an electric boiler, but there are general points that need to be fulfilled:

- It is better to put the device in a separate room, where younger members of the family can not get.

- The power cable is laid so that water does not fall on it. To do this, use plastic or metal boxes. For the same reason, do not lay the cable under the water pipes.

- Pipes are attached to the wall so that they do not damage the body and parts of the boiler with their weight.

- The wire cross-section must correspond to the current strength, and the unit body must be connected to the grounding device.

To begin with, the case is attached to the wall on special awnings. The height above the floor for the heating element of the boiler is at least 1.5 m. Other models can be installed below. Usually at the bottom of the boiler there is an inlet pipe for cold or cooled liquid, and at the top there is an outlet with hot water. Pipes are connected to the pipes using American cranes.

An expansion tank and a dirt collector are mounted to the return current line to collect garbage or scale pieces. There should be a tap next to clean the sump.

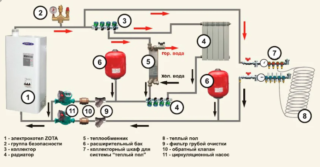

For induction boilers, the installation is more complicated, since it is necessary to insert a circulation pump into the main line, as well as a safety group: a pressure gauge, a safety valve and a device for removing air from the system. A sump and an expansion tank are also installed on the return line.

Particular attention is paid to the selection of the cable section and the installation of the control unit for emergency shutdown of the device. Work is carried out according to the scheme specified in the technical passport of the boiler.

Energy saving

The operation of an electric boiler will consume energy for which it is necessary to pay and prices for which are constantly growing. In order not to throw away finances, it is recommended to work to reduce heat losses that can occur through cracks in wooden windows, single-pane windows in metal-plastic constructions, an uninsulated ceiling or floors between floors, roofs not insulated with heat insulation, and the floor.

For insulation, you can use inexpensive materials - mineral wool, foamed polyethylene, polyurethane foam.

Choosing a boiler for different purposes

Electrical equipment for heating small rooms - garages, baths, summer kitchens - can be quickly installed and connected. This is an advantage, since there is no need to go to authorities and seek permission for a gas boiler.

Depending on the area of the room and the material of manufacture (wood, brick, sippanels), an electric boiler of the required power is selected, as well as suitable according to other requirements - the number of circuits and the connection method.

Electric boiler for a bath

For a bath built of wood and insulated with synthetic materials, you do not need a powerful boiler. It is enough to calculate according to the formula 1 kW / 10 square meters. If you need to quickly heat the room, choose an electrode or induction boiler. If the bath is located next to the house, the heater can be turned on in advance, as it takes longer to heat up.

Since utility rooms are used infrequently, a unit of a domestic manufacturer, which can be saved on, is quite suitable for a bath.

Electric boiler for a private house

For a private house, saving on heating is inappropriate, since the device may fail at the most inopportune moment. It is known that units of foreign manufacturers have a longer service life than domestic ones, so they work without breakdowns, but with the prevention and flushing of the system every 2 years.

From the heating elements you can choose the boiler Evan. From domestic - the electric boiler Proterm Skat, which can be connected to a single-phase network without additional modifications. The electric boiler Evan has a different modification with the ability to connect to a different electrical network.

Popular manufacturers of electric boilers

TOP manufacturers of the best models of electric boilers include:

TOP manufacturers of the best models of electric boilers include:

- Bosch - a term of operation of 15 years;

- Vaillant eloBlock - works without interruptions for 10 years;

- Protherm - service life 10 years;

- Tenko Premium - 10 years;

- Leberg - 10 years old;

- Hi-Therm - 10 years;

- Kospel - 15 years old.

The rating is based on a comprehensive analysis of the functions and equipment of the devices. The ability to work in a cascade with other heating systems, as well as the ability to connect the “warm floor” function, is also taken into account. In some models, the basic equipment does not provide for the circulation pump, expansion tank and safety group. These devices will have to be purchased separately, which will affect the final cost of the equipment.