Maintenance of the heating system is its main effective and long-term operation. Compliance with the technology will increase the time of uninterrupted operation, which, in turn, will affect the cost of maintenance. Traditionally, work on cleaning and filling the coolant is carried out in mid-autumn. However, it is possible to start the heating system at home in winter: order, the instructions are different from the standard.

Possible problems when starting heating

What can a user encounter when trying to turn on the system in winter? The main danger lies in the freezing temperature. If the launch of autonomous heating systems is carried out according to the traditional scheme, then in case of mismatch of external factors to the required, an emergency can occur.

For example, consider the procedure that is regulated by manufacturers under normal conditions:

- Drain the old coolant. Already at this stage, at low temperatures, problems can arise. When using water, there is a high probability of the appearance of so-called long plugs. They also cause damage to pipes and radiators;

- Cleaning and crimping. Even if antifreeze has been poured into the heating before, the restart of the closed heating system is impossible without its preliminary cleaning. In winter, you should choose special fluids that do not freeze at sub-zero temperatures;

- Choosing a new coolant. If it is impossible to heat the room to the required level, it is best to use antifreeze. Water can freeze even at the stage of pouring into pipes.

There may also be a problem with checking for leaks. The formation of ice in the places of damage to the heating elements will not give a complete picture of the state before heating the coolant. For central networks, heating starts in an apartment building are carried out according to a strictly worked out scheme only by representatives of the management company. Consider the difference in the order of starting heating in the winter on the example of a private house. It is in such cases that the most problems arise.

Before starting heating in an apartment building, you must open all the shutoff valves on the radiators. Otherwise, air jams are highly likely.

Preparing and inspecting the system for launch

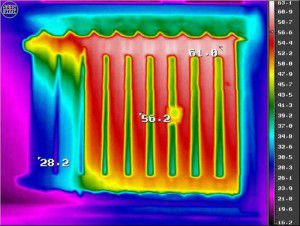

The first start of heating in a private house after a long period of inactivity should be carried out as soon as a detailed analysis of the premises has been done. It includes temperature measurement in each room where the pipeline passes and heating devices are installed. If before this, water was filled in the pipes, check for ice plugs. You can identify them by a characteristic sound - it will be several tones higher than if there is fluid in the line.

A more professional approach is the use of a thermal imager. It will show where the temperature is below zero and thus, even before filling the coolant, possible malfunctions can be eliminated. Then you need to perform the steps in the following order:

- Measure indoor temperature. If it is below zero - try to raise it with the help of heat guns or other similar devices;

- Investigate the most likely occurrence of gusts or defects. Most often they appear in threaded joints, fittings, or rotary elements of pipelines;

- Drain coolant. The correct start of the heating system in the winter is recommended only after a complete replacement of water or antifreeze in the system.

After checking the condition of all heating components, it is necessary to replace the gaskets in the places of installation of thermometers, manometers, air vents, etc. Damaged pipe sections are replaced; if necessary, a new stop valve is mounted.

When the old coolant is drained, its approximate volume can be visually checked. If it is less than expected, it means that there are blockages or ice plugs in the pipeline or radiators that impede the release of water.

For closed highways, the correct start-up of the heating system in winter includes a test of the centrifugal pump and the expansion tank. For open lines with stable pressure, the liquid level in the expansion tank is controlled.

Flushing the heating system

During the operation of heating, scum inevitably appears on the walls of pipes and radiators. If it is not removed on time, then the efficiency of the heating system will be significantly reduced. This is due to a decrease in the working diameter of the line. In addition, the thermal conductivity decreases - most of the thermal energy is spent passing through the scum layer and the walls of the pipes or radiators.

To avoid this, the complete instruction for starting the heating system includes a flushing procedure. It can be performed in several ways, each of which has its advantages and disadvantages. To increase the effectiveness of this event, special equipment should be used - a pump with a tank for flushing liquid.

Chemical flushing

The most popular type of cleaning, as it allows you to remove the overwhelming amount of scale and sediment. However, you need to carefully choose the composition - some of them negatively affect the condition of plastic pipes and connectors. It is noteworthy that in some cases, the start of central heating is also performed with their application. The composition of the purifier must contain special inhibitors that form an additional protective layer on the inner surfaces of the main and heating devices. It helps prevent rust.

Hydrodynamic flushing

Often the first start of the heating system is done after a hydrodynamic flushing. Compared to chemical, this method is characterized by a large mechanical effect on external elements in the system. Ordinary distilled water under high pressure passes along the entire line. All debris that may remain after installation inside the pipes will be washed away.

Hydropneumatic flushing

The technology is similar to hydrodynamic, but differs in a larger value of the created pressure. It is used to start an autonomous heating system, in which there is a high probability of the presence of a formed thick layer of scale. As an additional device, you can use a pneumatic gun, with which you can accurately flush individual heating elements - batteries, boiler heat exchanger, etc.

Before starting the heating system in a private house, it is necessary to make a pressure test. It is performed for closed pipelines with operating pressures up to 3 bar.

To carry out the launch of the heating system in winter, and in particular - washing, you can rent the necessary equipment. The attached instructions will help you understand the principle of operation of a particular pump.

Pressure testing of the heating system

In some cases, crimping is neglected. However, it is important when starting a closed heating system. This is especially true when work is performed in winter.The essence of this method is to check the state of the elements of the system by creating excess pressure inside it.

Using a special hydraulic pump inside the line, pressure is increased, which exceeds the standard by 1.25 times. As a result, components containing latent defects fail. They can be identified visually - the appearance of leaks (hydraulic crimping) or air bleeding. To start the heating system in the winter, a similar check should be carried out according to the following scheme:

- The choice of method is hydraulic, air. It is recommended to choose the first one, since it will more accurately determine the "weak" places in the highway;

- Connecting the pump to the circuit;

- The creation of excess pressure. At this stage, the maximum possible parameters must be strictly observed. If they exceed the permissible by 1.5 times - the failure of even serviceable components before this is possible;

- Visual monitoring of the state of heating and draining of the liquid.

Before starting heating in an apartment building, representatives of the management company must warn tenants about pressure testing. At this time, you must be at home and monitor the condition of the battery and pipes. In case of defects - immediately contact the management company to eliminate them.

Standard instructions for starting a heating system do not include indicators of maximum pressure for crimping. If you perform this procedure yourself, the probability of error is high. Therefore, it is for its implementation that it is best to invite a specialist.

Coolant selection

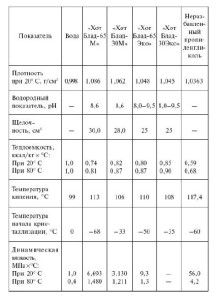

The next stage of starting the heating system in winter is the choice of coolant. Despite the emergence of new non-freezing liquids, water remains the best option for filling. This is due to its heat capacity - 1 kcal / (kg • deg). The lower this indicator - the more energy you need to spend on heating the house. That is, the amount of heat that is expended for its heating will be transferred to the room with minimal losses.

However, in addition to this, the negative aspects of water use must be taken into account. The main one is crystallization at sub-zero temperatures. This will cause ice plugs in pipes and batteries. Therefore, the instructions for starting the heating system must indicate that it is not recommended to use water at sub-zero temperatures in the room. In this case, antifreeze should be poured. It differs depending on the composition.

Ethylene Glycol Based Fluid

Currently, it is not used for the first start of the heating system. This is due to its high toxicity - if it comes into contact with the skin or respiratory tract, it is dangerous to human health. But at the same time, in its parameters, it is as close to water as possible. The difference is only in higher density.

Propylene glycol

It is part of a standard nutritional supplement and is completely safe for humans. The disadvantage is the high cost and high heat capacity.

Glycerol based coolant

This is currently the best replacement for propylene glycol. These antifreezes have a higher heat capacity and are also safe for use in both open and closed heating systems. The disadvantages of glycerol include its fluidity. Therefore, when planning the heating start-up procedure, it is necessary to add the replacement of rubber gaskets with paronite ones. In this way, small leaks can be avoided.

All types of antifreeze can be bought both in the finished state and in concentrated form. When preparing the solution yourself, you need to take into account the lower limit of freezing. For 40% of the composition, it is -30 deg.

Heating system filling

After completing all the above steps, you can go directly to filling the heating system. The technique differs depending on its design and type - closed or open. But in any case, for the correct start-up of an autonomous system, it is necessary to know its main operational parameters - temperature operation and pressure.

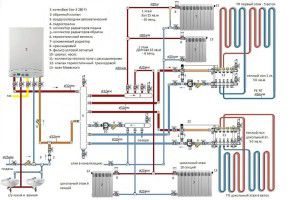

To fill the coolant, a pipe for filling is usually installed in the pipeline design. It should be at the lowest point. When starting a two-pipe closed heating system, the following procedure should be followed:

- Connection to the inlet pipe of the tank from the coolant;

- Using a pump, water is pumped into the system;

- At the same time, it is necessary to monitor the condition of the air vent and Mayevsky taps in radiators;

- The system is filled until the pressure gauges have reached the desired level.

For an open pipeline, the procedure for starting heating in a private house can be simplified. Usually it is carried out through an expansion tank, located at the highest point of the line. The coolant must be filled up to the level until the expansion tank is 1/3 full.

When starting the heating system in winter, the boiler power must be set to the minimum level. In this way, the high temperature difference in the forward and return pipes can be avoided. The boiler power increases gradually.

To start the heating system in the winter, the above procedures and instructions will avoid component breakdowns. To reduce the likelihood, it is best to fill the coolant in separate circuits, if any, are provided by the circuit. This can be done with a register.

Video instruction for filling with heating medium will help to do it yourself: