In an autonomous heating system, a situation is often observed when radiators remote from the boiler give off less heat than those installed closer. The problem may lie not only in the large length of the highway, but also in an incorrectly composed scheme with a single circuit. Is it possible to make several of them and what are heating circuits, their description and balancing?

Problems balancing heating circuits

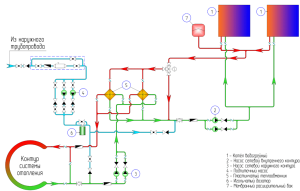

The simplest example of a competent distribution of the coolant among several consumers is the heating of a multi-storey building. If a single-circuit scheme were used in its creation, some consumers would be left without heat. Therefore, the building has several heating circuits. The same principle can be applied to the autonomous system of a private house or cottage.

But first you need to figure out what a heating circuit is. Imagine that branching occurs at a certain section of the pipeline, and part of the coolant is sent along a separate circuit to another room. In this case, the length of each of the circuits may be different, since the rooms in the house have unequal areas. As a result, water with a different degree of cooling enters the common return pipe. But the big problem is the uneven distribution of heat in the house. To eliminate this, balancing of the heating circuits is necessary.

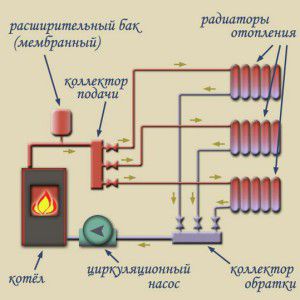

This set of measures aimed at uniform distribution of coolant, depending on the length of each branch of the heating system. This can be foreseen at the design stage:

- If the system has two heating circuits - Their length should be approximately equal. To do this, make the separation of pipelines in the areas of each room;

- Distribution manifold installation. Their advantages are the ability to use special elements that automatically limit the flow of coolant. The defining indicator is the length of the heating circuit;

- The use of special devicesregulating the volume of hot water depending on the set values.

The result of the measures taken to balance the heating circuits should be a uniform temperature in all rooms of the house.

Calculation of balancing of heating circuits must be done at the design stage. It is not always possible to modify an existing system.

Adjustment of a water heat-insulated floor

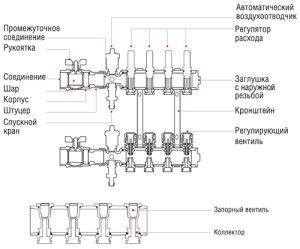

Most often, the problem of thermal control is encountered in the design of a water floor heating system. That is why in his scheme a collector is mandatory, which is responsible for this closed heating circuit.

Separate circuits are connected to each inlet and outlet pipe. Their length may not always be the same. Therefore, the design provides for regulatory mechanisms:

- Flow meter - mounted on the return manifold. It performs the function of adjusting the quantity of water depending on the length of the heating circuit;

- Temperature controllers - limit the flow of water by temperature.

For the initially correct distribution of the coolant in the closed heating circuit, it is enough to make a simple calculation. The main indicator is the volume of each branch. The sum of these values will correspond to 100%. For the calculation, it is necessary to divide the volume of each circuit and calculate the coefficient of limitation of water inflow into it.

When balancing a warm water floor with a large area, it is recommended to take into account the number of turns in each circuit. They create additional hydraulic resistance.

Collector heating system

It is much more difficult to organize an even distribution of the coolant in a circuit consisting of two heating circuits. Until recently, conventional tee valves were used for this. However, they could not provide the desired result - a larger volume of water passed along the path of least hydraulic resistance. The result was a significant temperature difference in the rooms.

Having found out what a heating circuit is based on the example of warm water floors, the same model was transferred for the entire house system. Only in this case it became possible to create separate highways for each room or group of rooms. Most often, a dual-circuit heating system is used, which in comparison with the classical one has the following advantages:

- The ability to adjust the flow rate of the coolant in each branch using flow meters. Thus, balancing of individual heating circuits is carried out without changing the parameters of the entire system;

- If necessary, the heat supply to the premises can be completely eliminated. This may be necessary to save ongoing heating costs;

- The absence of a large influence of the length of the circuit in heating on the temperature mode of operation. The main thing is to install regulatory equipment.

The disadvantage of this scheme is the large length of the highways. On average, 30-40% more consumables are required to create collector heating than for the classic version. This increases the total amount of coolant, which increases the required power of the heating boiler.

It is not advisable to install collector heating for single-storey houses with an area of up to 120 m².

Balancing valve

But what if there is already a ready-made heating system initially, and the above mechanisms for adjusting the circuits are missing? Then, in such closed heating circuits, a balancing valve can be installed.

The closest equivalent to the balancing valve is a conventional stop valve. But only in contrast to it, the valve mechanism provides for the possibility of automatic or manual adjustment of the coolant flow into a specific heating circuit. For large systems, automatic models are chosen. If it is possible to carry out manual periodic adjustment - you can install a mechanical analog.

The principle of its work is to limit the flow of coolant into a separate highway. To do this, the design provides a rod that performs a locking function.

When choosing a specific model, you must pay attention to the following parameters of this equipment:

- The value of the working fluid pressure is maximum and nominal;

- Pressure difference in return and supply pipe. This is important, since excess coolant is redirected to the return line;

- The value of the flow rate of water in the pipes;

- Nominal temperature mode of the system.

These characteristics can be taken from a preliminary calculation of heating, or obtained experimentally by the method of simple calculations. The cost of the balancing valve directly depends on its functionality, the diameter of the pipe and the material of manufacture. Well-established automatic stainless steel models.

Having learned what heating circuits are and how to balance them, you can optimize the performance of the entire system. But at the same time, it is important to monitor the pressure readings in each of them so that excessive hydraulic pressure is not created.

You can see an example of balancing by watching the video material: