Domestic air conditioning systems are not able to provide a comfortable microclimate at large facilities. In trade and concert halls, workshops of enterprises, sports complexes, the installation of industrial air conditioners is necessary. This equipment is characterized by increased power and performance in the cold. With its help, a decrease in temperature, humidification and purification of air in the served room are provided.

The device and features of an industrial air conditioning system

Depending on the application, air conditioners are divided into three categories:

- household;

- semi-industrial;

- industrial.

The last group includes installations that control the climate in administrative and medical institutions, trading floors, production halls, sports and entertainment complexes with an area of more than 250-300 m2. Features of the equipment are: the complexity of the device, high cooling capacity and cost. The working life of industrial climate systems is 20-30 years, taking into account continuous operation. Domestic installations cannot function in such a rhythm.

Air conditioners for large rooms are designed not only for forced air exchange, they perform flow processing. The functions of an industrial air conditioning system include filtering, draining or humidifying, heating or cooling the air.

Significant parameters when choosing HVAC equipment are energy efficiency and unit cost, calculated per 1 kW of productivity in the cold.

Types of climate systems

There are several types of industrial air conditioners. The equipment is selected depending on the purpose of the premises being serviced and the requirements for the climate system.

Multizone installations VRF and VRV

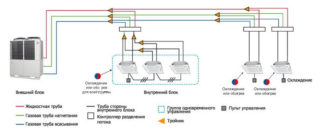

Multizone air conditioning system allows you to simultaneously serve a large number of rooms. It consists of one powerful outdoor unit and dozens of indoor modules. Between themselves they are connected by highways from copper pipes.

The abbreviation VRV was patented by Daikin, it means “variable refrigerant volume”. Other companies had to slightly change the name of the system (VRF), operating on the same principle.

Each indoor unit is equipped with a valve that controls the amount of freon. The ability to change the refrigerant volume allows you to set individual air parameters in the rooms.

Advantages of the multizone system:

- cost savings in comparison with the equipment option of each room with a separate air conditioner;

- various options for placement of internal modules, not taking up free space;

- centralized block management;

- in rooms with a high accuracy the specified microclimate is supported;

- low noise.

In multi-zone air conditioning, various types of indoor units are used:

- Cassette devices. The modules are installed under a false ceiling, do not take up the space of the room. The lower part of the housing is made in the form of a grill or distribution blinds. The design provides uniform air supply. Devices are characterized by high power.

- Channel systems. Installation of an industrial air conditioner involves placement under the ceiling. The stream of the processed air is distributed on air ducts with decorative lattices.A feature of the system is the ability to cover a room with an area of up to 300 m2 and a capacity of up to 25 kW.

- Column or floor units. Devices are characterized by significant weight and lack of fasteners. Are established in places where it is impossible to place other types of climatic equipment.

- Wall mounted. The indoor unit is placed on the wall. The number of modules depends on the power of the equipment and the size of the room.

Chiller-fan coil system

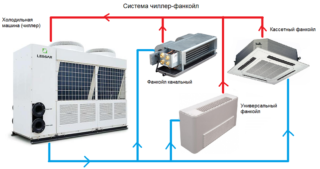

The system is assembled from an outdoor unit (chiller) and several heat exchangers inside the building (fan coil units). The refrigerant in the working circuit is water. The chiller cools the liquid to 6-8 ° C and, with the help of pumps, delivers it to the fan coil. Chillers are manufactured with air, water and remote condenser. Advantages of the system:

The system is assembled from an outdoor unit (chiller) and several heat exchangers inside the building (fan coil units). The refrigerant in the working circuit is water. The chiller cools the liquid to 6-8 ° C and, with the help of pumps, delivers it to the fan coil. Chillers are manufactured with air, water and remote condenser. Advantages of the system:

- chillers are energy efficient, easy to install and operate;

- have no restrictions on the number of indoor units and the length of the pipeline;

- It is possible to add ventilation and space heating.

Central and roof air conditioners

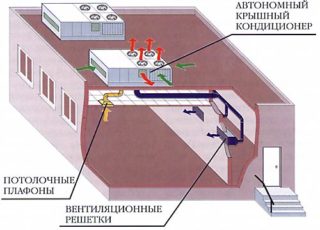

The central air conditioner for industrial premises consists of standard sections of air intake and supply, filtration, cooling, irrigation and heating. For work connection to a chiller is required. Reliable and durable climate complex is used in conjunction with other systems - multi-zone, chiller-fan coil.

The central air conditioner for industrial premises consists of standard sections of air intake and supply, filtration, cooling, irrigation and heating. For work connection to a chiller is required. Reliable and durable climate complex is used in conjunction with other systems - multi-zone, chiller-fan coil.

Roof air conditioners (rooftops) are installed on the flat roof of buildings. They cool / heat the air to the specified parameters and process it before serving it in a serviced room.

Precision Air Conditioners

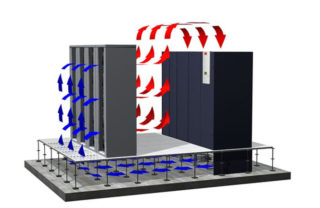

A precision installation is a type of cabinet air conditioner. To accurately maintain room humidity, the system is equipped with a hygrostat. The power of the device is in the range of 5-100 kW. Air conditioners consist of two units, the internal has the ability to distribute cold air through the upper and lower panels.

The accuracy of adjusting the conditioning of industrial equipment is 2% in temperature and humidity.

Choosing an industrial air conditioner

The use of industrial climate technology involves the maintenance of large areas. The equipment is distinguished by large dimensions, complex device and installation. When choosing an air conditioner for production, a theater hall or a hotel, many factors take into account:

- Power consumption - among industrial air conditioning systems, the most expensive are the central and roof climate systems, multizone VRF and VRV installations are economical.

- Design features - not all equipment has a function for adjusting parameters in individual rooms.

- When choosing a type of equipment, they are guided not only by its price, but also the cost of installation. Inexpensive roof air conditioners will require high cash costs for installation.

- Possibility of ventilation - the conditioning system is shaped according to the task being performed. In the “chiller-fan coil” circuit, a central air conditioner is connected, providing an influx of fresh air.

The list of factors that is standard for any climate technology matters:

The list of factors that is standard for any climate technology matters:

- area of the building, premises;

- the total amount of heat generated by the devices;

- the presence and location of sources of natural ventilation;

- the number of people in the room.

The type of climate system depends on the purpose of the building. For public, shopping and entertainment complexes, channel and cassette systems are recommended. Maintenance of industrial premises, workshops is carried out by central air conditioners or chiller-fan coil units. In medical institutions, research centers, museums, precision complexes are installed that support the specified parameters with high accuracy.