Freon is a mixture of gases, thanks to which the air conditioner cools the room. The refrigerant circulates in the system, evaporates in the heat exchanger and lowers the air temperature. Freon r 410a is the working gas of most modern air conditioners. He replaced the R22 freon, which adversely affects the ozone layer.

What is freon R410a

The information that r 410a refrigerant has become a replacement for R22 cannot be taken literally. Technical characteristics of freons vary, a split system designed for one type of gas mixture is not filled with another composition. Freon r 410a was developed in 1991 by Allied Signal. After 5 years, the first air conditioners appeared, working with the new freon. The aim of the developers was to replace obsolete gas mixtures containing chlorine. Compounds of the CFC group (chlorofluorocarbon), when released into the atmosphere, destroyed the ozone layer, enhancing the greenhouse effect. The new freon meets all the requirements of the Montreal Protocol. Its effect on the depletion of the protective layer of the Earth is zero.

The information that r 410a refrigerant has become a replacement for R22 cannot be taken literally. Technical characteristics of freons vary, a split system designed for one type of gas mixture is not filled with another composition. Freon r 410a was developed in 1991 by Allied Signal. After 5 years, the first air conditioners appeared, working with the new freon. The aim of the developers was to replace obsolete gas mixtures containing chlorine. Compounds of the CFC group (chlorofluorocarbon), when released into the atmosphere, destroyed the ozone layer, enhancing the greenhouse effect. The new freon meets all the requirements of the Montreal Protocol. Its effect on the depletion of the protective layer of the Earth is zero.

The composition of freon r410a: R32 + R125. The chemical formulas of the compounds are difluoromethane CF2H2 (difluoromethane) and CF2HCF3 (pentafluoroethane). The ratio of components is 50% to 50%.

The composition is stable, inert to metals. It has no color, has a slight smell of ether. Under the influence of open fire decomposes into toxic components.

Pressure and boiling table

The working pressure of the refrigerant is proportional to the load on the compressor. In addition to this indicator, the pressure difference on the suction and discharge side affects the efficiency of the unit. Both characteristics of Freon 410a are high. With the same performance, air conditioners with this type of freon are more expensive than models with other refrigerants. The price increase is associated with the costs necessary for the manufacture of more durable units and parts.

The working pressure of the refrigerant is proportional to the load on the compressor. In addition to this indicator, the pressure difference on the suction and discharge side affects the efficiency of the unit. Both characteristics of Freon 410a are high. With the same performance, air conditioners with this type of freon are more expensive than models with other refrigerants. The price increase is associated with the costs necessary for the manufacture of more durable units and parts.

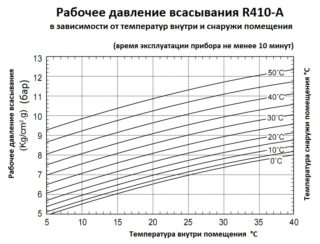

The table of the working pressure of Freon 410 in the air conditioner is presented in the form of a nomogram. It is compiled according to several indicators:

- Indoor temperature

- ambient temperature

- working suction pressure.

The actual pressure of the freon changes several times a day. Its value depends on temperature fluctuations and the selected mode. Under normal conditions, the gas used boils at a negative thermometer. The pressure generated by the compressor allows you to change the boiling point.

The boiling table of freon r410a, depending on pressure, is used when checking for leakage.

| T, C | -5 | 0 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 |

| P bar | 5,85 | 7 | 8,37 | 9,76 | 11,56 | 13,35 | 15 | 16,65 | 19,8 | 22,9 | 26,2 |

Advantages and disadvantages of Freon R 410a

The refrigerant belongs to the group of hydrofluorocarbons. A promising composition is considered as an ozone-friendly mixture of HFC. The minimum temperature glide (0.15 K) equates it with properties to single-component freons.

The refrigerant belongs to the group of hydrofluorocarbons. A promising composition is considered as an ozone-friendly mixture of HFC. The minimum temperature glide (0.15 K) equates it with properties to single-component freons.

- A high level of specific refrigerating capacity does not require the installation of a powerful compressor.

- In the event of a leak, the amount of gas is easily replenished without loss of refrigerant quality.

- There are great opportunities in terms of reducing energy consumption of equipment.

- Cold performance is 50% higher than systems with R22 and 407c.

- Good thermal conductivity and low viscosity positively affect the efficiency of the system. Heat is transferred faster and with less cost to move.

Cons of freon:

- High working pressure in the system, which negatively affects the compressor, leads to rapid wear of the bearings.

- The pressure difference on the suction and discharge sides of the refrigerant reduces the efficiency of the compressor.

- The requirements for tightness of the circuit are increasing. The wall thickness of the copper pipes of the trunk should be greater than for R22.The minimum value is 0.8 mm. A significant amount of copper leads to a rise in the cost of the system.

- The refrigerant is not compatible with parts of HVAC equipment made from elastomers sensitive to diphthemethane and pentafluoroethane.

- The polyester oil used in the air conditioner is more expensive than mineral oil.

Specifications

In terms of physical properties, a mixture of two hydrofluorocarbons is close to azeotropic. During phase transitions, its temperature glide is minimal, almost equal to 0. This means that both components simultaneously evaporate and condense. Freon R 410a has a high cooling capacity. Improving performance allows you to reduce the size of HVAC equipment and refrigeration units. The refrigerant is non-toxic and fireproof, does not ignite in air.

At a freon condensation temperature r410a of 43 ° C, its pressure reaches 26 atm. For comparison, a similar indicator of R22 is 15.8 atm.

Physical characteristics of freon r410a

|

Characteristics |

Units | Value |

| Molecular mass | 72,6 | |

| Boiling temperature | ° C | -52 |

| Boiling point density | Kg / m3 | 4 |

| Critical temperature | ° C | 72 |

| Critical pressure | MPa | 4,93 |

| Temperature drift | ° C | 0,15 |

| Heat of vaporization | Kj / kg | 264.3 |

| Specific heat of steam | BTU / lb * ° F | 0,17 |

| Ozone Depletion Rate | 0 | |

| Global Warming Potential (GWP) | 1890 | |

| ASHRAE Security Group | A1 / A1 |

The absence of chlorine in both components of the freon does not harm the ozone layer.

High global warming potential refers to the shortcomings of the mix. The ejection effect is similar to R22. Refueling of the system is carried out only in the liquid phase. Transportation and storage are carried out in pink cylinders withstanding 48 bar pressure. Tanks are filled at 75% of the weight.

Application features

Freon is equally effective in split systems and chillers with screw compressor and water condenser. High pressure liquefied gas requires special components and parts. Constructive development of new models of climate and refrigeration equipment is underway. Technical characteristics allow it to be used in devices:

Freon is equally effective in split systems and chillers with screw compressor and water condenser. High pressure liquefied gas requires special components and parts. Constructive development of new models of climate and refrigeration equipment is underway. Technical characteristics allow it to be used in devices:

- centrifugal compressors;

- flooded evaporators;

- pump refrigeration units.

The new freon has found application in air conditioning systems, domestic heat pump systems. The mixture with azeotropic properties is suitable for equipment with direct evaporation and flooded heat exchangers. Due to its high density, freon is used in domestic and industrial installations:

- transport cooling systems;

- air conditioning installations in offices, public buildings, industrial facilities;

- household refrigerators;

- trade and food refrigeration equipment.

Together with Freon 410 a, synthetic (polyester) oil is used. The disadvantage of this product is its high hygroscopicity. Refueling eliminates contact with wet surfaces. We recommend the use of products of the brands PLANETELF ACD 32, 46, 68, 100, Biltzer BSE 42, Mobil EAL Arctic. Mineral oils are not compatible with the refrigerant; their use will ruin the compressor.

Before filling the system, the working circuit must be evacuated. Moisture and contamination are not allowed in the refrigerant. When refueling, special equipment designed for high pressure is used. For safety, avoid the appearance of open flame near the cylinders of r 410a freon.