The microclimate of any room is the result of the interaction of temperature, humidity, cleanliness and air mobility. Air conditioning systems, which gradually replace conventional air conditioners, are helping to achieve the optimal combination. The most effective systems are called the “chiller-fan coil”.

Description of climatic equipment

“Chiller-fan coil” is a ventilation system that provides air conditioning through the use of non-freezing liquid (antifreeze or ethylene glycol-based solutions) as a cooler.

“Chiller-fan coil” is a ventilation system that provides air conditioning through the use of non-freezing liquid (antifreeze or ethylene glycol-based solutions) as a cooler.

The package includes:

- chiller - unit cooling coolant;

- fan coil - a local heat exchanger with a fan that passes heated or cooled air through it;

- capacity for heating water - replaces the chiller in the cold season;

- pumping units that circulate coolant between the chiller and fan coil;

- expansion and storage capacities;

- the unit that controls the air conditioning system as a whole.

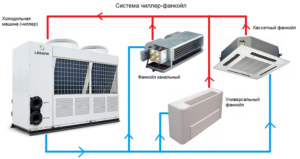

The equipment can be installed in any building and used for air conditioning in a single room or in all rooms. When organizing a system in large buildings, it is additionally required to equip with air ducts and pipelines that ensure the flow and circulation of air and coolant. In this case, one chiller will supply a cooled solution to several fan coil units.

A universal equipment configuration that would provide air conditioning at any facility does not exist. It must be adjusted to specific operating conditions.

Main advantages of the chiller-fan coil system:

- the use of non-freezing liquids as a cooler, ensuring the system is working at a negative ambient temperature;

- the possibility of a gradual increase in system capacity, which allows for phased commissioning;

- fan coil control and the entire system as a whole is carried out using the built-in or remote control panel;

- unlimited remoteness of indoor units from the location of the chiller (depends only on the power of the pumping equipment).

Fan coil selection

Choosing a fan coil for a particular room, experts first of all pay attention to:

- device cooling capacity (volume of air that needs to be cooled in one hour);

- airflow length;

- type and geometric dimensions of the room (length, width, height, volume, presence of windows, etc.).

The intended installation location is important. If the unit will be used to heat the room, it is advisable to place it closer to the floor, and if for cooling - as close as possible to the ceiling.

The device of the fan coil and the principle of operation

The fan coil installed in the room is the final link in the chiller-fan coil air conditioning system.

It includes:

- heat exchanger;

- filter block;

- fan;

- electric heater (if necessary);

- drainage pump;

- control panel (built-in, remote or remote).

Each fan coil is equipped with shut-off and control valves and a condensate drain pan.

All components except external control panels are assembled in one housing, which can be installed under the ceiling or on any wall of the room.There are housing units mounted behind suspended ceilings or decorative wall panels, as well as models equipped with one (two-pipe) or two (four-pipe) heat exchangers.

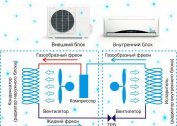

The principle of operation of the fan coil: the air from the room is sucked in by the fan and, passing through the heat exchanger, is heated or cooled due to the indirect effect of circulating fluid coming from the chiller. The filter purifies the air leaving the device. Additionally, a small amount of fresh air enters the fan coil from the ducts connected to the central air conditioner. Thus, in the "chiller-fan coil" system, air conditioning is carried out with simultaneous ventilation of the room.

Fancoil is not a self-contained device. For its operation, additional equipment is needed that cools warm air. It is this function that the chiller takes over.

The advantage of indoor units is that they are turned on only when necessary, by heating or cooling the air in a particular room to a predetermined temperature.

Classification

Fancoils are divided into 3 classes:

- Universal (wall, floor and ceiling).

- Channel.

- Cassette

Regardless of class, they can be manufactured in two- and four-pipe versions. The category is determined depending on whether it is allowed to mix refrigerants in the room, which are used for cooling and heating. If possible, install a two-pipe fan coil, if not, a four-pipe fan coil.

Universal fan coils

Designed for installation in horizontal or vertical position. In appearance, they practically do not differ from the indoor unit of a conventional household air conditioner, but at the same time they have functional differences:

- fluid is circulated in the heat exchanger;

- a three-way valve is installed that regulates the flow of refrigerant or coolant.

Usually installed in rooms without false ceilings. For installation, a variety of fasteners and installation elements (legs, brackets, etc.) are used, the type of which is determined by the embodiment.

The cooling capacity of most universal fan coils is small - from 1 to 8 kW. Higher power devices look bulky and unattractive for open installation.

Four-pipe units are designed for installation under windows. They are connected to air conditioning and central heating systems. In the winter season, a fan coil installed under the windows of the apartment is air-conditioning and heating the air, acting as a heating battery.

Cassette Fan Coils

Provide uniform distribution of conditioned air in 2 or 4 directions. Designed for placement in the sub-ceiling space of large areas, for example, trade and exhibition halls. To achieve a greater effect, it is recommended to connect the ventilation ducts.

To ensure a comfortable speed of movement of cold air, it is necessary to install cassette fan coil units at a height of at least 2.7 m from the floor. Upon completion of installation work, the installation site is closed with a decorative false panel of the original design.

Most often, the cooling capacity of cassette devices does not exceed 5 kW. They are produced in compact cases with overall dimensions of 600x600 mm. More powerful devices have dimensions of 800x800 mm, 850x850 mm and 600x1200 mm.

The advantage of cassette fan coil units is a simple condensate drainage system based on built-in drainage pumps.

Channel Fan Coils

Flush mounted devices that look like internal blocks of channel split systems. Components are completely hidden behind a suspended ceiling. Only decorative grilles come out.Channel units differ from cassette fan coil units in the possibility of creating a network of ducts that provide air from several gratings. This makes it possible to organize cooling or heating in several rooms.

They are mainly used for air conditioning of administrative and public buildings, as well as office centers, the layout of which resembles Open Spase offices. At the same time, the air supplied through the ducts through a large number of grilles is evenly distributed over all rooms.

Open Spase offices are large premises, divided into small rooms by partitions that do not reach the ceiling.

The advantage of channel units is a wide range of cooling capacity, which ranges from 1 to several hundred kW.

One of the most important technical characteristics of channel fan coils is the pressure of the built-in fan. There are units of high and low pressure type. If the grilles through which the air is supplied are located in the immediate vicinity of the fan coil, choose a device with a low-pressure fan. When there is an extensive network of air ducts that provides air conditioning at a great distance from the fan coil, an aggregate with a high-pressure fan is needed. However, such devices are distinguished by their large dimensions and high noise level.