Climatic technology is designed to make life comfortable, providing coolness in the summer heat. The cost of split systems is quite high, and taking into account the installation by specialists from the service, it turns out to be unbearable for ordinary consumers. You can save money if you buy an air conditioner out of season, and install it yourself.

DIY air conditioner installation

Do-it-yourself split-system installation takes place in two stages: preparation (selection of a place, search for tools, purchase of consumables) and installation. Work is carried out in strict accordance with the rules and technical requirements. The miscalculations and errors of the installers are the main reason for the breakdown of climatic equipment. Prior to installation, you should understand the device and the principle of operation of the air conditioner.

Do-it-yourself split-system installation takes place in two stages: preparation (selection of a place, search for tools, purchase of consumables) and installation. Work is carried out in strict accordance with the rules and technical requirements. The miscalculations and errors of the installers are the main reason for the breakdown of climatic equipment. Prior to installation, you should understand the device and the principle of operation of the air conditioner.

The system consists of two blocks:

- external (condenser) has a compressor that changes the state of aggregation of the refrigerant;

- internal (evaporator) using a fan drives air through a freon-cooled heat exchanger.

The blocks are connected by a copper pipe route through which refrigerant circulates.

The efficiency of the equipment depends on the proper placement of the air conditioning modules and high-quality sealing of the joints and connections of the pipeline.

Brief instructions for installing a split-system with your own hands include the following items:

- Selection and preparation of a place for installation of an external and internal module of an air conditioner.

- Installation of an external unit.

- Installation of the indoor unit.

- Laying communications: freon highway, drainage hose, electric cable.

- Evacuation of the system and trial run.

Mounting tools

Installation of an air conditioner is associated with the installation of blocks inside and outside the room and the laying of the track. To work, you need the following tools:

Installation of an air conditioner is associated with the installation of blocks inside and outside the room and the laying of the track. To work, you need the following tools:

- hammer drill;

- drill;

- locksmith set (wrenches, screwdrivers, level and more);

- Vacuum pump;

- gauge manifold;

- rolling;

- pipe cutter.

In the process of self-assembly can not do without consumables:

- brackets and hardware for the outdoor unit;

- 2 copper thick-walled pipes with a meter equal to the length of the route plus a margin of 30 cm;

- electric cable with a cross section of 1.5-2.5 mm2;

- heat-insulating materials in the form of a sleeve for the freon route;

- reinforced adhesive tape.

Place selection for indoor and outdoor unit

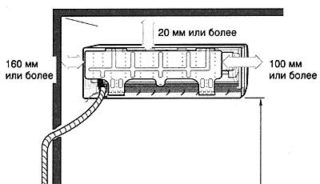

When choosing a location for installing blocks, they comply with technical requirements and provide opportunities for subsequent maintenance. There are no special problems with the location of the internal module. Installation Rules:

- 15 cm from the ceiling;

- no closer than 150 cm from large objects that impede the flow of air;

- far from heating appliances;

- it is impossible to close the block with curtains and curtains;

- cold air should not be allowed on the bed or workplace.

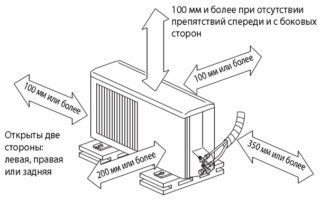

Installation of an external unit requires taking into account a large number of factors:

Installation of an external unit requires taking into account a large number of factors:

- on the ground floor, the distance from the earth is not less than 2 m;

- the module cannot be installed on the sunny side, near trees;

- the distance from the rear panel to the wall 15-20 cm is necessary for the removal of hot air;

- the support must support the weight of the outdoor unit.

Do-it-yourself installation of the air conditioner is carried out not only near the window, but also on the wall or parapet of the balcony. For apartments of high-rise buildings this is the best option. The risk of injury during installation is reduced, maintenance does not cause problems.The balcony should be unglazed or have wide-open frames.

When choosing installation sites, the length of the route must be taken into account. It is not recommended to make the pipeline more than 7 m and less than 3 m. An additional filling with freon will be required, heat losses will increase. The best option is to place parts of the air conditioner on one wall or on adjacent ones.

Mounting the outdoor unit

The external air conditioner module is mounted using metal brackets. Support elements are selected by weight and model of a split system. Safety margin should exceed the recommended load by 2 times. Reliable fastening with minimal vibration is possible only on a flat base. You can not install the unit on the insulation, fixing is done to the wall.

Marking is preliminarily performed and the holes for the dowels are drilled. The brackets are mounted horizontally. The block is fixed on supports with 4 bolts. In a private house, appliances are not at risk of damage or theft, and on the ground floor of a multi-storey building it is better to install an anti-vandal grate.

Indoor unit installation

A mounting plate for the indoor unit is provided. On the wall there is a place for fasteners. Pre-checked the absence of electrical wires at this place. The plate is set horizontally using the building level and is securely fixed to the support. The block is fixed on the mounting element, its location in the plane is checked. Distortions will cause condensate to leak from the drain pan.

A mounting plate for the indoor unit is provided. On the wall there is a place for fasteners. Pre-checked the absence of electrical wires at this place. The plate is set horizontally using the building level and is securely fixed to the support. The block is fixed on the mounting element, its location in the plane is checked. Distortions will cause condensate to leak from the drain pan.

After mounting two blocks with a puncher, a hole in the wall is knocked out under the freon track, drainage and electric cable. Its diameter is not less than 45 mm. Be sure to form a bias towards the street. To protect the pipes from damage, a sleeve is inserted inside the hole.

Electrical wiring

It is recommended to lay a separate cable from the distribution panel to the air conditioner with the installation of the machine. A copper wire is selected, the number of cores depends on the type of connection: single-phase - 3, three-phase - 5. For low-power models, you can use the existing outlet. In the documents of the air conditioner there is an electrical circuit showing the location of all the elements. Before connecting, it is carefully studied.

A cable connecting the modules is laid between the indoor and outdoor units. It is placed in a protective corrugated pipe. The ends of the wires are stripped and attached to the terminals of the pads. Separately marked ground wire. Connecting the blocks according to the scheme, check the operation of the device.

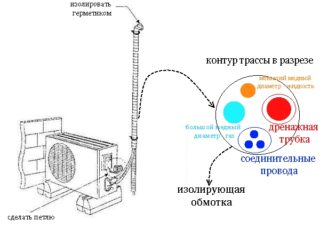

Freon Route and Drainage

The refrigerant responsible for the removal of heat circulates in the system along the route from copper pipes. Material is sold in bays. A part is cut along the line of the highway, taking into account a margin of 20-30 cm. A pipe cutter is used for work. The tool cannot be replaced with a hacksaw; the cut will be rough. Any roughness in the pipes provokes the leakage of freon. There is also the possibility of ingress of copper chips. At the time of installation, the edges of the products are closed with plugs.

A heater is put on each tube in the form of a sleeve made of polyurethane foam or rubber. Joints of the material are glued with reinforced tape. Thermal insulation eliminates the formation of condensate. After insulation, threaded flanges are put on the pipes. Further, the edges of the products are expanded. A complex procedure that requires experience and a special tool can be replaced with a ready-made kit with pipes expanded at the factory.

A heater is put on each tube in the form of a sleeve made of polyurethane foam or rubber. Joints of the material are glued with reinforced tape. Thermal insulation eliminates the formation of condensate. After insulation, threaded flanges are put on the pipes. Further, the edges of the products are expanded. A complex procedure that requires experience and a special tool can be replaced with a ready-made kit with pipes expanded at the factory.

Communications have two ways: hidden or open. In the first case, a strobe is cut out along the marking line from the air conditioner to the hole in the wall. This option is optimal at the repair stage, in another case it makes no sense to perform dusty and laborious work. Trunk pipes are laid along the wall and hidden behind a decorative plastic box.

The easiest way to organize condensate drainage is to drain the hose to the street. If it is not possible to carry out the procedure, the fluid is sent to the sewer. In this case, a siphon is installed to cut off unpleasant odors.

Installation of the drainage pipe is carried out with a bias in the direction of moisture removal, sagging and rises are not allowed. The end of the hose should be 60-80 cm from the wall so as not to erode the structure.

The components of the communications are connected into a common harness using tape, in this state they are pulled through the hole. Nuts are used to connect copper pipes to service block fittings. When you open the connection ports of the indoor unit, nitrogen exits, this is normal. The union nuts are tightened with a wrench, soft metal provides a tight connection. In a similar way, pipes are connected to the external module.

Evacuation system

The evacuation procedure removes air, dust particles and moisture from the system. For its implementation, a special pump is connected to the external unit through a manometric manifold. The process takes 20-30 minutes. After the gauge needle drops to -1 Bar, the equipment turns off. Within 30 minutes, monitoring is carried out, if the pressure does not change, the system is tight and ready for filling with freon.

A vacuum pump is an expensive equipment that does not make sense to purchase for the installation of one split system. Some craftsmen replace the evacuation of the route by purging with nitrogen or freon. In this case, moisture remains, causing a quick compressor failure. To perform the installation efficiently, the vacuum pump is rented.

Refrigerant filling and system testing

To start the freon, a hex wrench is required to open the valve on the liquid port. The refrigerant will begin to fill the system with a characteristic hiss. After filling, the hose mounted on the gas fitting is removed. This leaves part of the refrigerant. Work is carried out in compliance with safety measures - with gloves and goggles. The port is closed by a plug. Installation is complete, it remains to test the air conditioner.

Choosing the installation of a split system with your own hands do not forget that the store’s warranty on equipment is lost. Service in the service center will be paid.