For specialists, installation of air conditioning systems does not seem at first glance any difficulties, but in reality it is a very time-consuming process, in addition, it involves maintaining certain documentation.

Terms of reference for installation of air conditioning

Before proceeding with the installation of HVAC equipment, the designer draws up a technical assignment for the installation of an air conditioner, which includes:

- description of the object with all architectural features and its exact address;

- requirements for the installation of air conditioners, taking into account these features;

- description of the necessary equipment and materials.

The most voluminous is the paragraph, including the requirements for the installation of air conditioning systems, namely a complete phased description:

- punching holes in the walls;

- mounting brackets and blocks to them;

- laying freon highway;

- connecting interconnect wires and power cable;

- installation of a drainage hose;

- the process of crimping and vacuuming the refrigeration circuit;

- installation of circuit breakers and connection to an existing network.

Most companies do not make up the technical task for the installation of one air conditioner, as an employee of the company leaves the place and puts on an approximate plan for the subsequent installation. In this case, meeting the requirements for installing an air conditioner will not be a problem, so the majority of companies work according to a simplified scheme, because experienced technicians are unlikely to have difficulty with a standard installation of a wall split system.

If an order is received for large volumes, where it is required to carry out work on installing several units of equipment at a large facility, then the designer cannot avoid creating technical specifications for the installation of air conditioners. In this case, each stage for each device will be carefully described.

Of particular difficulty is the installation of industrial air conditioners, such as roof, central, precision, cabinet, chillers. In the documentation, special attention is paid to calculating the total capacity of the equipment, potential network resources, and calculating the location of ventilation shafts, taking into account all legislative norms.

When the documentation is finished, they begin to fulfill obligations under the contract with the customer, that is, directly to the installation of the selected air conditioning system at the facility.

Standard installation and installation of the air conditioner in two stages

Typically, installation work of split systems can be carried out in two ways. The first involves the standard installation of the air conditioner in one stage, and the second in two stages. What is each option?

If you decide to do everything at once, then it will look like this:

- air conditioners first install the external and internal blocks with copper tubes and inter-unit wires;

- then the system is tested with vacuum and the device is connected to the network;

- the final stage will be commissioning and measurement of control readings - pressure, temperature, etc.

When carrying out a standard installation of an air conditioner for some reason is impossible or undesirable, for example, in winter, the customer may be offered to hang it in two stages, that is:

- first, connecting tubes are laid and their ends are isolated from atmospheric influences;

- subsequently carry out all other work.

Some teams carry out installation of an air conditioner in two stages in a slightly different way:

- first lay tubes + wires and carry out all installation work with the external unit:

- in the future, they carry out the installation of the indoor unit, pressure testing + evacuation, commissioning and make control measurements of the operating readings of the device.

If the air conditioner is mounted in two stages in winter, it is advisable to simply lay the freon line, clogging the ends of the tube, and leave everything else for the warm season.

In the cold season, there is a possibility of damage to both equipment for the installation of air conditioners and important elements of the refrigeration circuit. For example, when starting up in cold weather, the compressor loses much of its potential, and in some cases it immediately fails if it gets unheated oil, which is part of freon. Moisture may remain in the circuit, as evacuation to sub-zero temperatures does not guarantee 100% removal of its excess.

There is such a thing as non-standard installation, when additional services are required, for example:

- laying inter-unit communications in a strob in a wall;

- drainage drainage;

- installation of an external air conditioning unit not under the window

- extension of the freon highway.

When installing the outdoor unit above, on the side of a window or on the facade of a balcony, industrial climbers may need to be called.

Professional equipment

For proper installation of the air conditioner, professional equipment is required, which is divided into groups according to purpose.

Power tools:

- large and small perforators;

- grinder or chipper;

- screwdriver.

When working with rotary hammers you will need drills with a diameter of 6 and 8 mm, as well as a drill with a diameter of 55 mm.

Pipe tool:

- pipe cutter;

- pipe benders;

- a rimmer (a stripper);

- rolling.

For non-standard installation or installation of semi-industrial air conditioners with an extended track, you will need:

- burner;

- soldering iron;

- forceps;

- silver solder.

Refrigeration equipment:

- gauge station;

- Vacuum pump;

- scales for weighing freon;

- leak detector.

Locksmith tools:

- 13 mm open-end wrenches;

- 2 Swedish keys;

- hammer;

- nippers;

- pliers;

- knife;

- scissors for metal;

- screwdrivers.

Materials:

- copper pipe;

- insulation on the pipe;

- drain hose;

- 5 * 1.5 PVA wire for interconnects;

- PVA wire 3 * 1.5 for power;

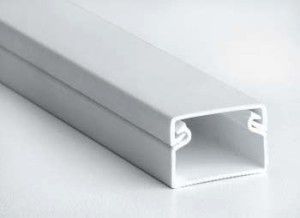

- cable channel 60 * 60 under the route;

- cable channel 16 * 16 under the supply wire;

- brackets for outdoor unit;

- fasteners for brackets;

- grounding plug;

- adhesive tape and electrical tape;

- cylinder with freon.

Correct installation can be performed by having all of the listed equipment for installing the air conditioner and not replacing one tool or material with another improvised means.

Looking at these lists, the reader himself will answer whether it is possible to install the air conditioner with your own hands. Do not believe many videos from the Internet about self-successful installation. At first, the device may function normally, but problems will arise in the near future. There will be no one to submit a claim.

The correct phased installation of a split system

How professional crews carry out the correct installation of an air conditioner is described in stages below. For example, the wall-mounted split system LG 18 is taken. It was located in an office with an area of 35 m², where 7 people are constantly located and 7 computers + 2 printers are installed. The room has 2 large windows that overlook the sunny side. Installation place - near one of the double-glazed windows opposite the copy machine.

Stages:

- Drilled a hole in the wall with a large puncher in the wall. To do this, use a drill with a diameter of 55 mm.

- Next, lay the cable channel 6 * 6 from the hole to the indoor unit.

- Mark holes for the mounting plate from the indoor unit and for the brackets for the outdoor unit.

- Drill the corresponding holes with a small puncher and fix the mounting plate with dowels and screws. The brackets are fixed with dowels 12 * 100 mm.

- Mount the external air conditioning unit on the brackets and fix it with bolts and nuts. Next, fix the internal module to the mounting plate.

- The route and interconnect cables are laid. Before that, a heater is put on a copper pipe. The tubes are necessarily flared. Connect to both blocks.

- Connect electrical connections. The wires are pre-cut, stripped, crimped, only then connected to the terminal blocks.

- Drainage is laid with a pipeline and connected to the indoor unit.

- Connect the power to the unit that is needed for this model. For the aforementioned air conditioner, the power cable from the shield was drawn to the outdoor unit.

- Carefully seal the holes for the track in the wall with mounting foam and close the lids on the box.

- The circuit is evacuated for at least 10 minutes. Open the taps and start the working gas.

- After they turn on the split system in test mode and check its operability: measure the pressure and look at the quality of cooling of the output stream.

This describes the installation of a conventional household split system. If you are installing a semi-industrial or industrial air conditioning system, then additional features arise in the installation of the room module.

Features of the installation of cassette and duct air conditioners

For example, the installation of a cassette split system begins with mounting the suspensions for the indoor unit on the anchor bolts in the cell of the suspended ceiling. When attaching the indoor unit, it is necessary to align it with the installed level from the ceiling, which is usually indicated by the manufacturer. Fixing takes place using mounting studs. Drainage of a cassette split system is most often diverted to a special centralized drainage system.

Cassette air conditioners may have such an option as a wired remote control. If they will use it, it is necessary to pull a separate electric wire from the indoor unit.

Channel split systems can have an extended network of ducts that are attached to the adapter and connected to distribution grids in each room. The indoor unit is installed behind the false ceiling of a residential or utility room.

Here, in the first place, it is important to calculate the required pressure of the outgoing air, since the length of the ducts and their number will depend on this. Their shape and style may also depend on this. There are air ducts:

- round and straight section;

- longitudinal and spiral construction;

- with flange, wafer and welded type of connection;

- flexible and semi-flexible.

It is also necessary to insulate and sound ducts. Insulation is required to prevent condensation. Soundproofed for quiet operation. Otherwise, such a split system will make noise.

The ducts of the channel split system are insulated with a special material - Kaflex (KFLEX). This is a special insulating material that can withstand large temperature differences.

To control the channel system with a wired remote control, you will need to draw a separate wire to the indoor unit as well as in the case of cassette air conditioning.

In fact, the main differences between different split systems are observed when installing the indoor unit, external modules are mounted and connected to the room everywhere in the same way, as described in the installation plan for the LG wall-mounted air conditioner.

Of course, installing any air conditioner with your own hands is a dangerous event, especially when it comes to semi-industrial or industrial systems.

General requirements for the installation of air conditioners

There are general rules for installing refrigeration machines.The main one requires a normal working volume of the room for the installation of equipment. The following conditions must also be met:

- the installation should always have free access for maintenance and repair work, while taking into account existing fire safety standards;

- it is necessary to ensure a normal intake and air outlet;

- provide strong support for heavy structures;

- provide isolation from moisture, fire, steam and direct sunlight;

- prevent noise above established standards.

Any project documentation more deeply reveals the requirements for installing a particular chiller.

Requirements for installing split systems

Specifically for split systems, there are also certain installation rules:

- installation of the external unit is done on a solid basis;

- brackets should be attached to the wall with reliable mechanisms;

- the distance from the wall to the heat exchanger of the outdoor unit is at least 10 cm;

- distance from the right side of the module - at least 10 cm;

- distance from the left side of the module - at least 40 cm;

- there should be no obstacles in front of the block within 70 cm;

- there should be free access to service ports;

- the indoor unit is placed away from heat and moisture;

- you can not install the unit in front of the doorway of the front door or a constantly open window;

- no interior items should interfere with the air outlet;

- air should not go directly to people and places of their frequent stay;

- provide high-quality moisture removal through a drainage hose;

- from the ceiling to the block should be at least 15 cm;

- the mounting plate is fixed to the wall with screws strictly level.

The column split system is additionally fixed to the wall for structural strength. For floor-and-ceiling and cassette systems provide the possibility of unhindered removal of filters.

To better understand what is discussed in the article, you can watch the video installation of air conditioners below.