You can increase the performance of the air conditioning system by warming the freon line. It is important to know what materials should be used and how to carry out the work so that the insulation for the air conditioning tubes is as effective as possible.

Features of warming the air conditioning

Home split systems need insulation. Insulation for air conditioning tubes allows you to get rid of moisture on the surface of the track, which in summer can form in large volumes and leak, leaving dirty spots on the walls under the outdoor unit.

Home split systems need insulation. Insulation for air conditioning tubes allows you to get rid of moisture on the surface of the track, which in summer can form in large volumes and leak, leaving dirty spots on the walls under the outdoor unit.

Thermal insulation of freon pipelines is also carried out in order to prevent loss of power of the device - part of it leaves through the heat transfer of the route. With protection installed, no condensation will form on the pipe surface.

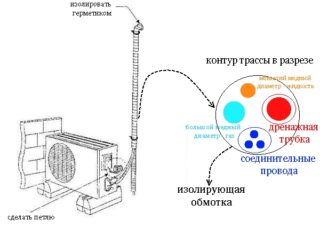

Isolation should start from the external unit of the split system. 2-3 cm must be moved back from the return nut so that it can be easily tightened to the fitting on the outer element. Subsequently, this gap is closed with vinyl tape. Usually the length of one insulation is enough to cover part of the track at the external unit, as well as in the wall of the house. As a result, the first seam of insulation is formed in the room.

For reliable fixation of the heat insulator in the pipe, it is glued with sealant at the joints. Insulation joints in the room are rolled on top with vinyl tape.

Electrics, copper pipes and a drainage hose are placed in a corrugated pipe. If the communications in the room are closed with a decorative box, it is not necessary to use an insulating winding.

Conditioner insulation procedure

The size of the insulation layer for split systems depends on the diameter of the nozzles. In apartments, pipes with a thickness of 6 mm are usually insulated. For this purpose, nonporous synthetic rubber is selected. The composition is not afraid of water, fireproof and counteracts the spread of flame in case of fire. The pieces of insulation are interconnected by vinyl tape.

It takes a lot of time to heat the insulation of the copper pipes of the split system, since it is necessary not only to wrap the elements of the route with the appropriate material, but also place them in a pre-made hole in the wall. These actions are performed in a specific sequence:

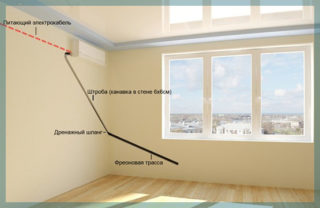

- Calculations are being made. They are needed to determine where the system will be placed. Also, thanks to preliminary measurements, you can take into account the location of the air conditioning units. Marking is done on the wall, and then the strobes are made.

- After gating, the track design is prepared. It is necessary to unwind the bay with tubes and put on them insulation material. It is better not to bend the pipes too much so that they do not break, and the tightness of the route is not broken.

- After preparing the route, it is laid in channels in the wall. Fasten the system to the mounting tape and dowel nails.

- After installing the entire system, the strobes cover up, returning them to their previous appearance. Now you can install the air conditioning units and conduct a test run.

When warming the track, it is better to crimp it. It is necessary so as not to damage the installed system during finishing work. Additionally, a monometer can be installed on the track to always know the pressure in the system. This measure reduces the risk of refrigerant leaks.

Isolation of the interblock track reduces energy costs. If you do not insulate the highway with freon, the climate equipment will work with lowered performance. In addition, condensation formed on the tubes can damage the connecting elements.

Track insulation is best done before all connecting elements are installed.The main thing is to choose the right size of the material, given the diameter of the tubes. The copper element is pushed into the heat insulator to the borders of the joints with the nuts. The heat insulator protects the track from damage in the gate during thermal expansion.

Features of the placement of the drainage hose:

- The hose is laid in the same gate with freon tubes. In this case, the route is carried out under a natural slope towards the drain of the accumulated condensate.

- Drainage is carried out separately from the main route - for such a case, an explicit slope is created only for the drainage hose. Freon tubes can not be laid in level. They are often carried along the ceiling.

- If gravity cannot drain the drain from the split system, a special pump is used to remove the condensing liquid under pressure.

When marking the strobes under the track, it is necessary to avoid sharp turns having a negative angle.

Insulation materials

Insulate the copper tubes of the air conditioner with the following materials:

Insulate the copper tubes of the air conditioner with the following materials:

- L’Isolante K-FLEX. The material is flexible and flexible. It is made of foam rubber having closed pores. Operational characteristics allow it to be attributed to high-quality products. Low vapor permeability and thermal conductivity provide ease of use of the material. It is characterized by high corrosion and fire safety.

- Energoflex. Often used to warm the track of air conditioners. The range of products of this brand is quite wide. The presented material has a closed mesh surface.

- Thermaflex. It has a lot in common with L’Isolante K-FLEX products.

Insulating the copper lines of the split system, it is necessary to monitor the tightness of the joints of the material.

For external insulation, it is important to choose a material that is not afraid of ultraviolet radiation, and is also able to maintain its properties at low and high temperatures. Such properties protect copper tubes from external factors.

Criteria for choosing thermal insulation for copper highways:

- Reliability of a heater. You should not save on consumables when installing the device, as this may affect its service life.

- The area of the insulating surface. The tubes are completely insulated. Fittings are also securely closed so wet places can be avoided.

- The presence of seams - their number should be minimal. Joints are carefully sealed.

For convenience, cables, drainage and insulated copper pipes are placed in a corrugated pipe.

Replacing the air conditioning drain pipe is no different from installing new copper pipes. The main condition that needs to be considered is the timely shutdown of the pipes and the discharge of refrigerant. It is important to be careful when working with freon, since it can adversely affect the skin. Replacing a copper track is similar to laying a trunk when installing a split system.

For modern air conditioning systems use a new type of material - chrome furniture pipe. It has high strength and efficiency. The main disadvantage of the material is that with minor mechanical damage it will have to be re-chromium plated.