Fatty impurities contained in the drains can block the tube gap, causing clogging. Fatty acids lead to the appearance of rust and destroy pipes, due to which the trunk ceases to function. Special devices — grease catchers connected to the sewage system — solve the problem.

Scope of grease traps

An important function of the grease trap is the filtration of wastewater from greasy, oily impurities and particulate pollutants.

Grease traps used in everyday life are installed in the kitchens of apartments, private houses, as well as in catering establishments: restaurants, cafes, canteens. Devices are placed directly under the sinks, or placed separately. They serve to trap fat washed off from dirty dishes. Devices are cleaned manually.

Additionally, exhaust ventilation systems are equipped with special grease traps.

Industrial grease traps are installed at large production facilities with a large number of oils, greases and greasy impurities in the drains. Cleaning industrial grease traps is an automated mechanized process. In accordance with the norms of existing SNiPs, grease traps are installed outside the premises of the enterprise. For example, in a sewer well located near a building.

Design features and working principle

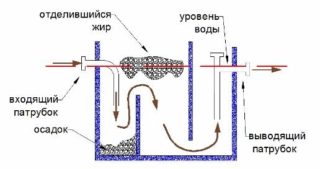

Structurally, grease traps for domestic and industrial sewers are no different. They consist of the following elements:

- compartment for collecting fat and oil;

- flasks with 2–3 compartments, in which drains are settled;

- inlet pipe;

- an exhaust pipe connected to a sewer pipe;

- sealed removable lid to prevent odors.

The principle of operation of the grease separator is a different density of waste components. Since water is heavier, greasy particles float. Entering the first compartment, the water stream rises little by little, and the fat accumulating on the surface is directed to the compartment intended for it. For the most part, skimmed water flows into the second chamber, where complete purification of the liquid from oil impurities that are not detained in the first compartment is performed.

Special enzymes can be added to the unit, the purpose of which is to break down accumulated fat. Their action significantly increases the time interval between cleansing the grease separator.

Material selection

Fat traps are plastic, fiberglass or made of stainless or galvanized steel. The first are used in everyday life, for this reason they are mounted indoors. The positive features include:

- Environmental friendliness. Polymer material is not harmful to the environment and human health.

- Practicality. Plastic allows manufacturers to produce installations of standard dimensions, while taking into account the individual needs of customers.

- Easy to maintain. The device can be cleaned manually using household chemicals.

- Durability. Plastic has a long service life, the installation can work up to 30 years.

For the normal functioning of grease traps, it is recommended to use a sensor for the level of deposits of fat and oil. The price of a grease trap made of polypropylene for sewage starts from 4000 rubles.

Fiberglass is made from fiberglass and a binder polymer. Fat separators have high strength characteristics.Due to this, they can be mounted indoors and outdoors.

Advantages of fiberglass grease trap:

- Resistance to hostile environment.

- The increased durability.

- Light weight and easy to clean - devices are easy to clean.

The cost of fiberglass models - from 7000 rubles.

Fat separators made of durable stainless steel are the most expensive of all similar devices. It is allowed to mount on the street and indoors. Grease traps are also available in galvanized steel. Quality indicators for these plants are lower than for stainless steel appliances.

Grease traps made of stainless steel are distinguished by high hygienic qualities, excellent performance, and a long service life. In addition, they are not afraid of rust.

The price of steel products starts from 13,000 rubles. Professional devices cost from 120,000 rubles.

Selection recommendations

Before choosing a fat separator, determine the installation location of the device. With this in mind, choose a design not only in size, but also in the material from which it is made. For outdoor installation, fiberglass separators or stainless steel products will be needed.

Grease devices vary in power and performance. Units with productivity up to two liters per second - household.

Devices with a capacity of more than two liters per second are attributed to structures installed in the production. Fat separators allow for the effective purification of effluents from fat-containing impurities up to 20 mg / l.

The performance of the device must correspond to the volume of wastewater entering the unit, or exceed this indicator.

Features of installation and operation

A grease trap can be made with your own hands from a polypropylene sheet and polymer pipes. But it’s easier to purchase a finished device, and install it yourself.

A grease trap can be made with your own hands from a polypropylene sheet and polymer pipes. But it’s easier to purchase a finished device, and install it yourself.

The separator is implemented, as a rule, in assembled form with already installed and sealed connecting tubes or adapters made of rubber. No special tools for installation work are needed. It is worth stocking up only with silicone sealant.

Do-it-yourself home grease separator installation on the sewer is carried out according to the following scheme:

- Determine the location of the separator: under the sink, washbasin or at the drain point of several plumbing fixtures.

- Prepare the surface for the apparatus. It must be horizontal, otherwise the waste will overflow.

- Check that the complete set has all the necessary shaped elements and fasteners.

- Connect the grease trap to the sewer pipes in accordance with the manual.

- Test before the first cleaning of the instrument. If there are no complaints, you can close the separator box.

During the installation of the grease trap, seal all connections with sanitary silicone sealant, fum tape, or other materials so that there are no leaks in the future.

The installation of large industrial installations outside the premises is carried out by professionals, since it requires the creation of a pit and concreting.

Grease traps need systematic maintenance. To do this, remove the top cover, after which a special spatula to remove the accumulated layer of fat inside. Wash separators with conventional household cleaning products.

The efficiency of the grease trapping device is possible only at a temperature of wastewater of not more than 40 degrees Celsius. If the temperature is higher, fats will begin to actively melt, which will lead to a decrease in the effluent purification efficiency.