The scope of the gutters is clearly defined: they must provide access to utilities laid in wells, in basements, in concrete sewers. They are used by services specializing in the repair and maintenance of engineering systems.

Definition and purpose of gutters

Sewerage and water supply systems in large cities is a complex and lengthy facility that requires periodic preventive maintenance and constant repair. Often there are accidents, which can be eliminated if there is access to underground utilities. It is provided by inspection wells formed of reinforced concrete rings. They are equipped with hatches and special "transport" systems - water stairs.

These are reliable constructions designed for lowering and lifting people who are in the service of public utilities. The staircase must support the weight of a large person who has a repair tool in his hands. Heavy equipment such as cables, diagnostic systems, and welding machines often descends into collectors using such devices. There are three different types of structures described:

- gutters;

- sewer;

- heat network.

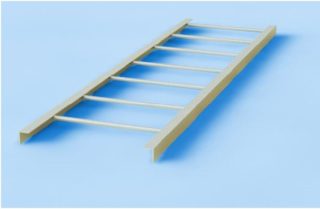

All three varieties have the same details: two parallel rungs that are secured by transverse steps. But each model has its own technical features.

Gutter stairs

Made of metal rod. The upper part of the two guides is bent in the shape of a hook. They provide attachment to the well ring. Such products are marked with the letters "VL" or "L", intended for installation in drainage, drainage or water wells.

To ensure safe descent, the described systems should be installed to the well wall and have the required length. It is possible to build, but in regulatory documents it is allowed to increase the length by no more than 50% of the original size. Each span of increased length must be attached to the wall of the well.

Sewer stairs

Instead of two, they have three guides. This design feature allows you to strengthen the equipment as close as possible to the walls of the trigger well and provide maximum safety for the descending person, on whose shoulders there is heavy repair equipment. The risk of falling is minimal. This is also achieved due to the special arrangement of the transverse bars. For marking, the designation "KL" is used. The product must be attached not only to the wall, but also to the neck of the hatch.

Heating ladders

The simple design does not provide for the presence of fasteners, so such products are simply installed in wells before lowering, and then removed after lifting. Belong to the class of portable equipment, which is part of the repair inventory. Heating ladders are not intended for lowering and lifting heavy equipment. Products are marked with the letters "LTS-1" or "L-16".

Permitted to use stationary installations ("L-15"), which are additionally equipped with handrails. The permissible height of this design is four meters. At the ladder for the manhole, the guides are made of a metal corner, and the steps are made of smooth reinforcement.

Each product is usually accompanied by a drawing, as well as a technical passport.It indicates the length of the item, as well as the diameter of the reinforcement used, weight in kilograms, step height.

Key parameters and specifications

The design and equipment of elements that provide the opportunity to descend into the engineering wells must comply with the requirements of SNiP and GOST. They determine the technical characteristics of products: weight, length, height, material selection and methods of processing. The main parameters are displayed in the documents attached to the product, help to choose and acquire the described equipment correctly.

- The mass of the stairs is a variable quantity. But there are maximum and minimum values for each type of product. For example, a meter of stairs in a sewer well should not weigh more than 25 kg. The stationary ladder class VL-2 has a maximum weight of one meter reaches 45 kg.

- The length of the product according to GOST should correspond to the height of the well, but it should not be less than 11 m.

- The reliability of the structure is determined by the weight that the steps of the launching equipment are able to withstand. According to the standards, it is assumed that each withstands weight up to 120 kg (the mass of a person with repair equipment).

- The current rules determine the choice of the method of protecting metal from corrosion, therefore, mainly the products described are made of stainless steel, of a rod with a diameter of at least 25 mm. When choosing other materials, paints and a primer are used that can protect the metal and prevent rusting.

Replacing stairs is troublesome and costly from a material point of view, so it is important to immediately purchase options that meet the stated requirements and ask the manufacturer for certificates confirming GOST standards.

Folding structures made of aluminum can only be used to service wells located in private areas. Their compliance with GOSTs and SNiP is also regulated by law. Displayed in factory certificates.

Features of installation and operation

Installation of stairs in manholes is carried out in accordance with existing rules. Their design is attached to the walls with the help of special brackets made of metal corners, dimensions 50x50x5. The distance to the bowstring should be at least 10 cm. The minimum distance between the bottom of the well and the very last step of the stairs should not exceed 30 cm.

If portable equipment is used, metal hooks should be present on its top. They will help to fix the staircase to the neck of the hydraulic structure and fix it in the right position. From below, vertical guides are equipped with rubber and steel plates to ensure the safety of a descending person (in specialized circles they are called “thrust bearings”).

When choosing a ladder that will then be used to lower it into a hydraulic well, it is necessary to pay attention to the correspondence of its design and manufacturing method to safety and reliability standards. They are regulated by SNiP and GOST. These factors should be taken into account in the independent manufacture of the described equipment.