Storm sewage - communication to remove excess rain / snowfall from hard surfaces. The main element of the system is the drainage tray. It may vary in the material of manufacture and dimensions, but one function is performed - the transportation of effluents to the city receiver or a private septic tank.

Definition and purpose of drainage trays

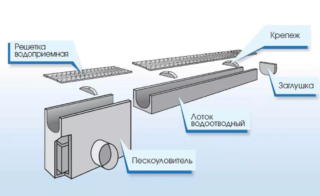

A gutter with a U-shaped or U-shaped section is called a drainage tray, regardless of the material of its manufacture. The upper part of the product is a durable protective grille made of polymer, cast iron or galvanized stainless steel. All gutters for water drainage from the roadway are produced strictly according to GOST, since they have high expectations regarding strength and durability.

A gutter with a U-shaped or U-shaped section is called a drainage tray, regardless of the material of its manufacture. The upper part of the product is a durable protective grille made of polymer, cast iron or galvanized stainless steel. All gutters for water drainage from the roadway are produced strictly according to GOST, since they have high expectations regarding strength and durability.

Use catchment trays for the following purposes:

- open drainage of concrete coverings: foundation, blind area, garden paths;

- removal of rain or melt water from autobahns and city / country roads;

- diversion of industrial effluents;

- collection and transportation of water from car washes, gas stations, runways.

In some cases, concrete gutters can be used as channels for laying cables. Such products are not used as a drainage system in the ground. Special perforated pipes made of fiberglass or other elastic material are needed here.

Types and device

Structurally, the sidewalk trays for water drainage look like a truncated pipe from above. The gutter has an incomplete diameter. U-shaped products, U-shaped and trapezoidal, are distinguished. The latter is produced with a factory telescopic slope for cascading drainage along the highway. Without fail, each tray is equipped with a protective grill. It prevents garbage from entering the sewers.

Structurally, the sidewalk trays for water drainage look like a truncated pipe from above. The gutter has an incomplete diameter. U-shaped products, U-shaped and trapezoidal, are distinguished. The latter is produced with a factory telescopic slope for cascading drainage along the highway. Without fail, each tray is equipped with a protective grill. It prevents garbage from entering the sewers.

Two types of gutters are distinguished: horizontal and vertical.

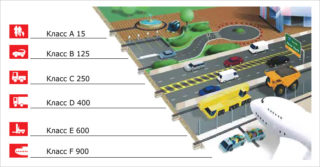

According to the load on the gutters, their types are distinguished:

- A 15. Withstand dynamic load up to 15 tons. Such gutters are laid in pedestrian areas, on bicycle paths, in the garden of a private house.

- At 125. The maximum load is up to 12.5 tons. Stacked in parking lots and in areas of city roads.

- C 250. Load up to 25 tons. Stacked at large car washes, in car service, at gas stations.

- D 400. Withstand loads up to 40 tons. Most often used for storm sewers on roads, highways, in large industrial enterprises.

- E 600. The maximum load level is 60 tons. Mounted in the area of logistics centers, large warehouses. In this class, the gutters of PPK Apatek, eco-gutters, and Biolot are made.

- F 900. Load class up to 90 tons. The trays are used for the installation of hydraulic stormwater in airports, at military bases.

Materials of manufacture

Drainage trays are made from durable materials. The most popular are concrete, polymer, composite.

Concrete gutters

Products are classified as E600 and F900. Made by vibropress. As a result, monolithic trays have several advantages:

- high strength to mechanical stress;

- inertness to moisture and aggressive environments;

- lack of corrosion;

- resistance to temperature fluctuations;

- durability (50 years or more).

The disadvantage of concrete can be considered the weight of the products. For laying gutters, it is necessary to use special equipment, which is expensive. Because of this, trays are not used in private construction of reinforced concrete products.

Composites (polymer concrete and polymer sand mixture)

Polymer concrete trays are produced with the inclusion of special resins in the solution.They make the final product more ductile and also light. With concrete strength, the tray can be laid without the use of special equipment. In addition, polymer concrete gutters have a smoother inner surface, which prevents siltation of storm sewers.

For the production of polymer sand (composite) products using the pressing technique. The mixture consists of quartz sand and polymer chips. The resulting tray has the following positive characteristics:

- high strength and inertness to shock loads;

- resistance to aggressive environments;

- low level of water absorption;

- light weight and the ability to work alone when laying sewers;

- favorable cost;

- environmental friendliness of products.

Polymer sand trays have a strength class of C250, so they are not suitable for laying on large-scale objects with a high load.

Polymers (plastic)

From HDPE and polypropylene, trays are manufactured in class A, B, C. They are ideal for private construction. Plastic gutters have special stiffeners, which prevents them from breaking even in heaving soil. The advantages of such products include:

- high strength;

- resistance to temperature extremes;

- inertness to chemical inclusions;

- wear resistance;

- long term of operation;

- simplicity of installation (plastic is easily cut and joined).

For laying stormwater in a private home, it is better to use polymer gutters.

Tray sizes

Reinforced concrete gutters for rainwater drainage have a length of 500 to 3000 mm. In rare cases, it is possible to manufacture trays of concrete with a length of 6 m. In this case, the internal hydraulic section varies in the range of 100-500 mm. The width of the gutters ranges from 400-1900 mm.

The length of one section of the polymer tray for drainage is 1-2 meters. The inner diameter varies in the range of 60-311 mm.

Metal (cast-iron) trays are used extremely rarely due to their high cost and huge mass.

Criterias of choice

Going after the gutters, it is worth taking into account the following nuances:

- Throughput and product load class.

- The material of manufacture. The transportation process and the complexity of laying the sewage system depend on it.

- The quality of joints and grooves. They ensure the integrity of the final communication.

- The presence of a factory bias. It is extremely important if it is not possible to create a slope when digging trenches due to the characteristics of the soil or topography on the site.

When buying, pay attention to the grille. It is desirable that it has a locking mechanism if the system is mounted in public places.

Installation Rules

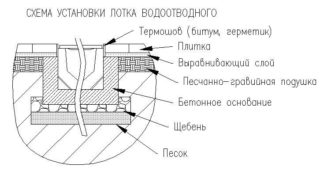

Regardless of the material of manufacture, the gutters are laid in the same way:

Regardless of the material of manufacture, the gutters are laid in the same way:

- Prepare a trench for the installation of stormwater. It is immediately done with a bias towards the receiver. At the same time, the depth and width of the channel is increased by 15-20 cm based on the further strengthening of the gutters.

- The bottom of the trench is well compacted and covered with sand with a layer of 10 cm. It is slightly moistened and also compacted.

- Concrete mortar is poured onto a sand cushion. It will serve as the basis for the trays. For greater strength, the fill can be reinforced.

- Once the concrete has dried, you can begin laying the gutters. They are carefully joined together. In polymer trays, seals are used. For concrete channels, bitumen or acrylic mastics are used.

- Once the trays are stacked, you can mount a special grid along their edges from the outside and fill the gutters from the ground with concrete mix. It will work as a limiting factor in case of possible heaving of the soil.

- Lastly, protective grilles are installed. It is important to ensure that they are located slightly below the site from which rainwater will be discharged.

Laying trays is best done on the control thread. So the evenness of the channel will be perfect.

Cost of water drain trays

The price of trays for storm sewers varies depending on the material of their manufacture, length, section, width, load and the manufacturer, the region of Russia. Average cost of rain gutters:

| Tray name | Section length | Inner section | Price, rub.) |

| Drainage tray polymer Standart | 1000 mm | 60 mm | 290 rub |

| Standart tray | 1000 mm | 160 mm | 440 rub. |

| Polymer gutter Standart | 2000 mm | 200 mm | 720 rub |

| Max polymer tray with cast-iron grate | 1,500 mm | 220 mm | 1100 rub. |

| Polymer drainage gutter with cast iron grate | 2000 mm | 101 mm | 1200 rub. |

| Concrete Standart Tray with Cast Iron Lattice | 1000 mm | 140 mm | 930 rub |

| Standart galvanized steel gutter | 1000 mm | 140 mm | 1660 rub. |

| Standart Concrete Tray with Cast Iron Grill | 1000 mm | 165 mm | 1670 rub. |

| Polymer concrete trench | 1000 mm | 140 mm | 870 rub |

| Reinforced concrete can tray LAN | 1000 mm | 300 mm | 840 rub |

| Concrete drainage tray Standartpark | 1000 mm | 140 mm | 370 rub |

| Composite tray "Ekolot" for Russian Railways | 4080 mm | 500 mm | 8 500 rub / running meter |

| Gutters "Biolot" composite | 2480 mm | 750 mm | 9500 rub / meter |

| Composite Tray Ekolot | 2080 mm | 1000 mm | 9000 rub / meter |

The price list shows prices for the most popular types of gutters. This will help to approximately calculate the total cost of the storm sewer. High-quality drainage of water from the building allows to extend its operation.