Plastic drainage trays are installed in hard-coated canals to collect melt and rainwater and discharge them into storm sewers. They are mounted at the same level with the ground surface and are overlapped by grates that prevent branches and debris from entering the cleaning system. The device of storm water inlets of this type is made of separate elements that are tightly joined together.

Scope and the device of plastic drainage trays with a lattice

Drainages from plastic modules are installed in country cottages, along pedestrian zones, in sports and playgrounds. The main condition is a small weight load per unit area. This is the main drawback of plastic trays: weight restrictions. By installing modules, in-ground basements are protected from flooding.

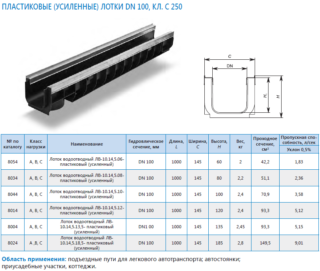

For the manufacture of rain gutters, polypropylene and polyethylene are used. Mineral based fillers are added to their composition. This increases the resistance of the material to aggressive compounds dissolved in rainwater. Trays work in a wide range of temperatures, ranging from -50 to +120 degrees. The measured length of the products is 1 m. The height varies from 6 to 79 cm, and the width is from 9 to 50 cm.

The niche of the element can be U-shaped, square and rectangular. Lattices for strong adhesion to the main structure are complemented by locking mechanisms.

Types of plastic trays for water drainage

Manufacturers conditionally subdivide products into several types:

- high-strength with stiffening ribs - used in areas with moving soil and heavy traffic;

- wear-resistant - anti-vandal coating is added;

- in-depth - water passage increases due to depth;

- universal - increase in cross section due to expansion.

The last two species have high throughput, which makes them suitable in areas with increased rainfall.

The main difference between plastic storm water inlets is a large assortment of sizes, which allows you to make the best choice without having to dig deep trenches.

Specifications

Polypropylene trays have a melting point of 160 degrees, frost resistance is maintained up to -54 degrees, density 889 kg / m3. The weight of the modules reaches 9-14 kg.

Polypropylene is a synthetic substance obtained by the synthesis of propene. It has increased strength and elasticity, does not absorb moisture, pushing it away from the surface, which increases the throughput of the modules. The material is resistant to most chemical compounds, non-toxic, easily mixed with coloring materials. The use of plastic products allows you to minimize labor and material costs, which affects their cost.

Criterias of choice

When planning storm sewers, a weight load is calculated, which depends on the availability of equipment and the number of pedestrians. In industrial and construction areas, at stations and airports, concrete trays are installed. To select the cross section, the throughput of storm water inlets and the planned amount of precipitation are calculated. The latter is obtained from a 25% increase in the average monthly rate, taken from the statistics of the Hydrometeorological Center.

When planning storm sewers, a weight load is calculated, which depends on the availability of equipment and the number of pedestrians. In industrial and construction areas, at stations and airports, concrete trays are installed. To select the cross section, the throughput of storm water inlets and the planned amount of precipitation are calculated. The latter is obtained from a 25% increase in the average monthly rate, taken from the statistics of the Hydrometeorological Center.

Lattices carry the main load.For their manufacture, steel, cast iron and polymers are used. Strength class is measured depending on the raw material. It ranges from A19 with a corresponding weight load of 1,500 tons, to the F900, designed for heavy vehicles.

Cast iron products easily carry the largest weight of up to 25 tons. The strength of steel grids depends on the manufacturing technology: cast have the lowest class up to 1.5 tons; but welded can withstand 12.5 tons, so they are installed in parking lots.

Lattices have a different design: from simple slotted and mesh, to skillfully crafted braids and ornaments, which gives the residential neighborhoods a unique look. Colors are chosen to match the road surface: black, gray and metallic. Optionally, you can order colored plastic products.

The type of trays is selected depending on the strength class and the appropriateness of use. Concrete elements have the highest strength class, but it is unlikely that their installation will be appropriate in the country, and plastic will quickly collapse in the production area.

Recently, new composite materials have emerged from which storm water inlets are produced. Polymer concrete elements have high strength, wear resistance. Their weight is much lighter than concrete products. They are not afraid of temperature changes and are inert to chemicals. Due to the smooth surface, their self-cleaning ability increases. Connect with a sealant. The service life exceeds 30 years, and weight loads are 25 tons. Products have a strength class from A15 to C250.

Polymer sand products are conglomerates of epoxy or polyester resins that bind silica sand or granite fine crumbs. The strength of the modules is increased, and the weight of the products is lower than that of concrete. The service life is 50 years.

Mounting Features

At the joints of channels from storm water inlets at an angle of 90 degrees, it is necessary to provide for the installation of caps on top. The sizes of plastic trays are easily adjusted at the place of installation. Their smooth inner surface allows the flow of water to flow unhindered into the cleaning system.

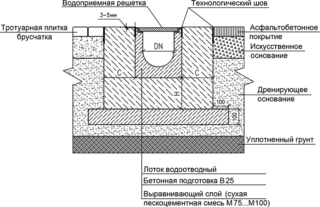

Installation of trays is performed with a slope of 1 cm per linear meter. A sand cushion is poured into the dug trench, which compensates for the pressure from the water freezing under the pipeline, leading to the protrusion of buried pipes. Before installing the trays, the bottom and walls of the trench are poured with liquid concrete to form a barrier. If possible, experts recommend adding gravel and gravel to the sand to fill in to level the swell. With loose soils, support elements are installed in the form of a metal wire or rods.

Mount the trays, cover their joints with sealant. Lattices are reliably fixed in order to avoid displacement and hit of garbage in a storm. The cover should be slightly below the surface by 3-5 cm.

Advantages and disadvantages of plastic trays

Plastic products have several advantages over other types of goods:

Plastic products have several advantages over other types of goods:

- durable (50 years) and durable;

- have a small weight;

- do not require heavy loaders for installation;

- profitable from a financial point of view.

Rain trays are laid on sidewalks, near buildings and structures, on sites and platforms. They do not interfere with communications. For their functioning do not perform special slopes that supply water to the storm water inlets. The surface drainage system requires a small cash investment. They are installed flush with the surface of the earth, do not interfere with the movement of people and vehicles.

Maintenance of plastic trays is much simpler than enclosed devices.

The cost of drainage elements

In appearance, a simple design requires thoughtful engineering solutions and the use of high-quality materials in long-term operation.

The prices of plastic drainage trays with gratings depend on the load class and material.The drainage tray AQUA-TOP with dimensions of 135mm / 100mmm class A (1.5 t) with a plastic grill will cost 500-600 rubles. a piece. In the same price range, the S’Park Class A kit with the same width and height of 90 mm (weight 0.76 t) with a plastic grill. Products are popular among owners of small areas where there are no increased requirements for the load.

Gidrolica Sport tray, load class A, LV-10.14,5.13.5 and dimensions D / W / H 119/28/14 with a galvanized steel grate costs 1800 rubles. The modules have increased wear resistance and a large selection of sections.

Storm water inlets are designed to protect land from erosion, to preserve building structures and technical structures from destruction. The most reasonable prices, from the point of view of the ordinary consumer, are sets of plastic. Their cost varies in the range from 300 to 500 rubles.