The submersible pump is a very convenient and multi-functional unit that has been widely used in various fields: from water treatment and removal of sludge and drilling mud from wells to cleaning sewer and drinking wells, extracting sand and clay from quarries. Often they are used for domestic purposes for pumping septic tanks and sedimentation tanks, replacing low-power and unable to absorb solid particles drainage and fecal pumps.

Submersible slurry pump device

A similar unit consists of the following parts:

- stainless steel or gray cast iron housing;

- power plant - an electric motor (hydraulic motor), on the shaft of which are located the working bodies of the unit;

- impeller (impeller) open type stainless steel;

- agitator (agitator) - a nozzle located on the shaft of the power plant, consisting of 2-4 blades, designed to destroy the bottom sediment and mix it with the liquid above it; for more effective performance of its function, the angle of the blades relative to the bottom plane is 60-80 degrees;

- an outlet pipe for connecting a hose to the pump that discharges a suspension of water and solid particles from the unit;

- electrical cable or hydraulic flexible hoses for supplying electricity / oil flow to the power plant.

To protect the impeller from damage by stones during immersion, a cylindrical casing with holes is used. In a submersible slurry pump with a hydraulic drive for supplying oil to the power plant on its upper part there are two nozzles for hoses.

Units are used when it is necessary to pump out not only contaminated liquid, but also the sediment located at its bottom. Therefore, their use instead of fecal and drainage analogues, pumping out only the liquid fraction of effluents, is impractical and disadvantageous - the cost of buying and operating a slurry pump is very high, part of its functionality will not be used if used for other purposes.

Principle of operation

The process of operation of a slurry submersible pump consists of the following operations:

- Placed strictly perpendicular to the bottom of the tank or reservoir, the pump abuts against the solid sediment located there;

- When the drive is turned on - an electric motor or a hydraulic motor - an agitator rotating at high speed destroys the solid bottom layer;

- The suspension formed during the operation of the mixer is sucked in by the impeller blades;

- The impeller’s rotating blades feed the liquid contaminated with solid particles into the outlet pipe, from where it comes to the surface or is pumped to another tank / reservoir under high pressure through a hose connected to it.

Due to the presence of an agitator, the pumping out of the suspension occurs without the use of filter elements.

Application area

Slurry pump due to its performance and reliability is widely used for the following purposes:

- cleaning wells from the bottom layer of sand;

- pumping of a layer of sludge from sewer sumps and highways;

- pumping out viscous domestic sewage;

- mining of sand and clay from quarries;

- deepening the bottom of silted beaches;

- sand removal during wastewater treatment in appropriate facilities;

- sludge pumping at mining and processing plants;

- drainage of construction pits flooded by rain and groundwater;

- cleaning of old and silted reclamation canals.

The submersible slurry pump has also been used for pumping clay and drilling mud from deep wells.

Main characteristics

The most important indicators characterizing the operation of a slurry pump are given in the table.

| Characteristics | Values |

| Maximum performance | From 20-40 to 300-430 m3 / hour |

| Power plant power | From 1.5-2 to 70-75 kW |

| Maximum head | 10 to 40-60 m |

| Operating temperature range, | From -35 to +45 |

| Density | 1.3-1.5 to 2.5 g / cm3 |

| Temperature | +1 to +35 |

| Acidity | 5,5-13 |

| Maximum size / solids content in the pumped liquid | 5-10 to 30-40 mm / 20-25% |

Maximum productivity, power and pressure has a range with a fairly wide range of values. This is due to the wide variety of models and their purpose. Household pumps are characterized by lower power, performance and maximum pressure, while industrial models are characterized by higher values of these characteristics.

Security systems

The following protective devices are used to prevent pump breakdowns:

- Leakage protection sensor - mounted in front of the sealing ring separating the engine compartment from the impeller working chamber. If water enters, to prevent a short circuit or leakage of oil, the power unit turns off.

- Temperature sensor - is installed in the stator (fixed winding of an electric motor) and serves to protect the unit during operation from overheating.

- Float - used in household units and serves to automatically turn off the pump when the level of pumped liquid falls below the protective casing on its impeller.

If at least one of the protective devices is turned off, the unit may fail at the most crucial moment.

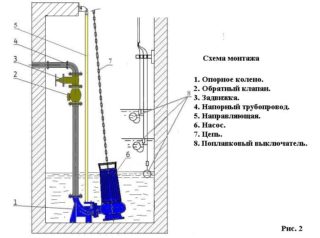

Installation Features

When pumping contaminated solid particles of water with a slurry pump, the following features of its installation are taken into account:

When pumping contaminated solid particles of water with a slurry pump, the following features of its installation are taken into account:

- The location of the unit is perpendicular or at a small angle to the bottom plane - with its working bottom surface, the pump must be in full contact with the bottom, otherwise the mixer will not be able to destroy and put into suspension the sediment located on it.

- Mobility - the pump must be suspended on the movable boom of the crane, the bucket of the excavator and in the process of pumping the liquid with their help should move along the bottom. This is necessary in order for the unit to pump out the maximum amount of bottom sediment, rather than digging into it while in a stationary state.

- Full coverage of the pump housing with working fluid for efficient cooling.

If at least one of the indicated mounting features is not observed, the pump will not be able to pump out the suspension well, dig into the bottom, or overheat during operation.

Advantages and disadvantages

The main advantages of slurry pumps are:

- high performance;

- reliability and durability of work units;

- the ability to work in difficult conditions;

- pumping water heavily contaminated with solid particles.

Among the shortcomings can be identified:

- high price;

- low maintainability on their own;

- high cost of spare parts.

Also, the disadvantages of such units include their large weight compared to drainage pumps.

Major manufacturers

Among a wide variety of companies producing slurry pumps, the most popular are:

- DAMBAT;

- Hycon;

- Dragflow

- Tsurumi Pump;

- Dynaset;

- Grindex.

These manufacturers have a wide range of models for domestic and industrial use.