As a result of improper installation or operation, solid waste accumulates in the sewer pipe and a plug occurs. The spent liquid does not enter the septic tank, but returns back to the house and drowns the room. To prevent this from happening, it is recommended to install a small and inexpensive device - a check valve, which prevents drains from entering the house.

What is a check valve for sewage

The situation with a blockage can occur in an apartment building and a private house, where the slope of the sewer pipe is not observed or plastic bags, rags are dumped into the toilet. In high-rise buildings, traffic jams can form between floors, so residents are at risk of flooding the bathroom with sewage coming from the upper floors.

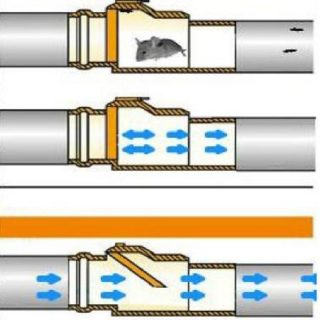

A non-return valve for sewage is a device that, at the right time, prevents the return flow of spent liquid into the room. Thanks to the simple principle of operation, water can only move in one direction - from the room. This is facilitated by the pressure created by the fluid that flows from the inside.

Scope of application

Check valves are used in pressure and non-pressure sewers and water mains. Basically, sewage systems become gravity, but if it is impossible to hold pipes under a slope, the liquid will leave more slowly, the probability of blockages will increase.

In pressure lines, a non-return valve is installed immediately after the pump so that sewage or drinking water does not pour back. Such devices are recommended to be installed in wells or wells. During operation, the check valve, or rather, its movable mechanism, also clogs over time. Therefore, it is necessary to provide for its installation in such a way that it can be disassembled and cleaned at any time.

In private houses, mice or rats can enter the room through sewer pipes. The shut-off valve prevents this.

The shutter mechanism is installed in places of sewerage where the pipe is turned at a right angle. This is considered an installation error, but in some cases it is impossible to turn in another way, therefore additional protection against blockage is put in the form of a locking membrane.

The non-return valve can not be installed if people live on the top floor in a multi-storey building.

Types of check valves and principle of operation

- At the installation site - internal or external. For external use, frost-resistant materials are chosen, the valve must have a large throughput.

- According to the installation method - coupling, flange and interflange. Clutch valves are installed indoors on pipes of small diameter. Flanged varieties are suitable for street sewers where large diameter pipes are used. The installation of interflange valves requires the use of welding.

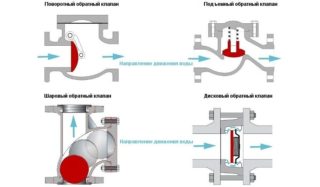

- By type of locking device - ball, lift and swivel. In a rotary design, a damper is used, in a ball - a sphere that prevents the return flow of drains. The lifting model works on a spring or under the influence of its own weight.

Each variety has its advantages and disadvantages. Wafer models are inconvenient to repair and clean, the swivel top has a cover that can be unwound and removed to remove blockage.In the lifting device, traffic jams occur more often, but they are easier to clean, as the device also has a removable cover. The ball mechanism is less clogged, but sometimes drains still seep in the opposite direction. The fountain from the toilet does not cause such an amount of liquid, so the model can be recommended as optimal.

Before buying, you need to analyze the quality and condition of your own sewer system, as well as the size of the pipes. Take into account:

- The diameter of the line. The cross-section of the inlet of the shut-off valve must match the diameter of the pipe.

- The material of manufacture. For a polymer system, a plastic device is more suitable - in quality and price. Polymers are not installed on a cast iron or steel line due to the difference in thermal expansion so that leaks do not occur.

- Installation method. For example, to connect a steel pipe and a plastic valve can only be flanged or coupling method, depending on whether the pipes are vertically or horizontally.

- The size of the fixture. For outdoor sewers or a common riser, larger models are chosen. For each individual plumbing fixture, a small device is sufficient.

The price of the product does not play a special role. It all depends on the state of the sewer. Do not buy an expensive shut-off valve model for an old sewer, which will soon have to be changed.

Materials of manufacture

It is advisable to install a check valve made of the same material as the sewer pipes so as not to waste money on additional adapters. If sewage is done from scratch, immediately select all the necessary details.

Materials from which valves are made:

- stainless steel;

- cast iron;

- bronze or copper;

- polymeric materials - PVC, polypropylene, metal plastic.

The cheapest and most convenient are plastic models. At the same time, their installation takes a minimum of time. It should be taken into account not only the material, but also the availability of space for the locking mechanism. There are vertical and horizontal devices. If there is no place for a horizontal structure, which is used most often, you have to put a vertical one.

It is not recommended to attach a heavy cast iron valve to the plastic pipe, as this may cause damage or collapse of the line.

Stainless steel

Suitable for installation on outdoor sewage and water supply systems. It has a long service life, as it does not lend itself to corrosion. The walls of the device are smooth, so organics do not have time to accumulate inside. Recommended for heavy street roads with heavy ground loads.

Cast iron

A material that has several modifications. Previously, only products with rough walls were produced, so pipes and all other parts had to be cleaned often. At the moment, you can choose products that have a smooth inner surface and do not require frequent maintenance. Cast iron structures are the heaviest of all, therefore, most often they are placed on city highways.

Polymer Check Valves

Since most private autonomous systems are made of plastic, non-return valves should also be consistent in quality. The most common are polyvinyl chloride and polypropylene. There are also metal-plastic and polyethylene products on sale. They differ in operating conditions:

- The temperature of the effluents. To drain the spent liquid from the bath, a material is needed that will withstand hot temperatures and not be deformed at the same time.

- Ambient temperature if the product is intended for outdoor sewage.

- Type of fluid transported. For domestic wastewater, the simplest material is enough, but for the removal of aggressive substances, chemically inert materials must be installed.

The coefficient of thermal expansion of materials should be almost the same if a non-return valve is used from one raw material and pipes from another.

Check Valve Dimensions

In the internal sewerage, the sizes 50, 100 and 110 mm are most often used. 50 mm - sinks, bathtubs, washing machines and dishwashers, 100 and 110 mm - for toilets. The most common model of ARV1.

For external systems, parts with a section suitable for the diameter of the pipes for which they are designed are produced - 160, 200, 250, 315 mm.

Installation Rules

The most convenient way to install a sewage check valve is during the installation phase of the entire system. In this case, it is easier to choose a place and calculate the size. But there are times when everything is already mounted, and then you have to put the locking mechanism. In such a situation, proceed as follows:

- They buy a part based on existing sewer pipes from a certain material, taking into account the diameter.

- Check the valve with water to let it pass in only one direction.

- Choose a place for installation so that it is convenient to conduct an audit.

- Read the instructions that came with the product.

- Cut a portion of the pipe along the length of the locking mechanism.

- Install the valve according to the instructions and the direction of water movement, focusing on the arrow. At this stage, you will need a sealant or a special sealing tape so that the joints do not leak.

After installation, check the operation of the device. If nothing flows, you can exploit. During operation, you will need to periodically clean the valve through the inspection hole. The instructions indicate the working hours of the internal parts, so it is advisable to change them on time.

Check Valve Cost

The cost of the check valve depends primarily on its size and material of manufacture. A large cast-iron sewer element will cost about 10 times more than a plastic one of the same size - from 8 thousand rubles apiece. A stainless steel valve will cost a little less. An ordinary pipe valve for a toilet with a diameter of 110 mm costs 9 - 10 thousand rubles.

The configuration of the device matters. Wafers are more difficult to install, but cheaper.

Consumer Reviews

Ivan: I had a story with these valves. We bought an apartment and did not ask why the previous owner lived there for only 2 years and started selling it. They made repairs in the bathroom, in the hallway, put a new laminate. After 4 months we decided to go to the sea. We arrive home, and the flood in the apartment. Yes, not anyhow, but the real fecal one. Laminate is not subject to restoration, apparently not the first day it flowed. We all understood why the previous tenant had moved out. We went to the neighbors with a proposal to change the pipes and the entire system. And they don’t need anyone - after all, it only flooded us. I had to re-buy building materials, ventilate the room. Before that, he consulted with a friend - he works on plumbing. He said to put check valves everywhere. Delivered, made repairs, live. Suddenly in the middle of the night there is a knock on the door - the neighbors on the second floor are drowning. Nothing got to us because of these valves, but they sailed to them in full. I recalled to them how I offered to change everything and went to sleep calmly. As a result, the neighbors on the second floor made repairs, installed the same device and warned the neighbors on the third floor in advance that they were next in line. A week later, a meeting of tenants was announced with a proposal to change the sewer. Changed, but I did not remove the valves just in case.