To access underground utilities through manholes, various types of hatches are used. Outwardly, they differ little from each other, although they have one goal - to protect passers-by from falling into the sewers. To understand which products should be installed, you need to understand the materials and methods of closure, as well as the sizes and shapes of the locking structures.

Scope of sewer hatches

The cover of the sewer manhole performs a dual function - it protects people from falling into the underground labyrinths of sewers, and also prevents clogging of the mine with debris and foreign objects.

Products are used wherever it is necessary to close access to inspection wells:

- storm sewer;

- domestic wastewater;

- electrical cable;

- telephone line;

- gas pipes;

- heating main;

- water pipes.

Depending on the expected load, the material and the method of opening are selected. In private areas, easier to use locks are installed, since the likelihood that the device will be removed is small. On your own site, you can install a less durable design of the sewer manhole, since the potential load on it will be small.

On the roadway you need durable products, for example, made of cast iron, which can withstand a constant load in the form of passing cars.

Well arrangement

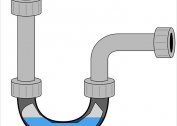

Sewer manhole is a product consisting of a housing and a cover. Both are made of the same material.

Sewer manhole is a product consisting of a housing and a cover. Both are made of the same material.

They produce lockable and non-lockable structures. The former are installed where there is access to various expensive equipment inside the mine and there is a high probability of intentional damage or theft.

Wells may be round, rectangular or square in shape. In most cases, round sewer manholes are used, since they are the most practical and economical.

There is a hole in the lid. It serves to open with special hooks or to control, for example, gas leakage in a gas pipeline.

The lid itself is made slightly convex so that water does not accumulate in it and does not freeze in the winter. Relief is necessary so that the wheels of cars or passers-by do not slip on the metal.

There is a special marking to identify the communications to which it leads:

- TS - heating main;

- T - telephone cable, varieties - GTS and MTS;

- MG - pipes of the main gas pipeline;

- GS - gas network;

- PG or G - fire hydrant;

- K - domestic wastewater (sewage);

- B - water supply;

- D - drainage or rain sewage.

Label hatches on top with letters or drawings. For example, access to an electric cable may be indicated by lightning.

Sizes of hatches and diameters of covers

Sewer manholes are distinguished by the class of loads:

Sewer manholes are distinguished by the class of loads:

- For pedestrian areas of a private area, light small-sized hatches are suitable. Marking according to EN-124 - LM (A15). A load of at least 15 kilonewtons (1 ton = 10 kilonewtons). Product weight 45 kg.

- In pedestrian areas of public places light, but more massive products weighing up to 60 kg are installed. The rated load is also equal to 15 kN. Marking - A15 L.

- The middle hatch has a safety margin of up to 125 kN and weighs 95 kg. Recommended for parking lots, sidewalks, park areas. Marking C (B125).

- Heavy sewer manholes are used on roads with an intense flow of passenger vehicles. The hatch weighs 120 kg and the rated load is 250 kN. Designation - T (C250).

- Heavy main hatches withstand a load of 400 kN, having a mass of 140 kg. They are used on interurban highways, where, in addition to cars, truck wagons and buses run. Marking TM (D400).

- Extra heavy sewer manholes are used in the construction of airfields and docks, where the weight of the transport exceeds 100 - 200 tons. Loads over 600 kN with a product weight of 155 kg. Marking - ST (E600).

In the designs of heavy and superheavy products, elements that cause a concentration of the load at one point and provoke a break in the metal are excluded. Such hatches are made on machines with numerical software, which ensures a tight fit of the cover to the body, eliminating uneven loads during collision.

The dimensions of the case and covers are greater, the more load the product can withstand.

| Title | Housing - dimensions in mm (diameter of the manhole / height) | Cover - dimensions in mm

(diameter / height) |

| Light small-sized less than 1 t | 720/60 | 600/25 |

| Lighter than 2 t | 750/90 | 690/55 |

| Lighter than 5 t | 750/90 | 690/55 |

| Medium less than 5 t | 750/100 | 690/50 |

| Heavy less than 25 t | 800/110 | 700/70 |

| Square less than 2 t | 640/640 | 600/600 |

These dimensions relate to standard cast iron designs. Although the industry produces hatches of different sizes. You can find very small - with a diameter of 38 cm - cast-iron, and polymer 1 m in size.

Lid locks

Locks are designed to prevent unauthorized entry into the system and theft of expensive equipment or cable, which is usually made of non-ferrous metals. Such wastes are resold to scrap collection points.

Locks prevent the cover from sliding, which can break under constant load. On the freeway, this leads to an accident, as the car’s wheel enters the hatch and the suspension breaks.

In pedestrian areas usually put two covers - locking and protective. The locking cap is located below and has a lock with a secret, which is performed in four versions:

- Spacer mechanism.

- Crab (or beam).

- The body and cover are connected by thread.

- A lock in the form of a flag between the body and the cover.

The most reliable are considered expansion and crab lock mechanisms.

Varieties of material

Sewer manholes are made of the following materials:

- gray cast iron;

- high-strength cast iron, which at rated load is 4-5 times higher than gray;

- polymer sand mixture;

- plastic;

- composites;

- strong rubber;

- reinforced concrete or concrete.

Each material has its advantages and disadvantages.

Cast iron products

Gray cast iron is an alloy of iron and carbon. It is characterized by low shrinkage, that is, it does not shrink and does not expand under the influence of temperatures. It is widely used in industry, since the cost of its production is relatively low, and its characteristics are not inferior to more expensive alloys and metals.

Advantages at operation of cast-iron hatches:

- durability;

- withstanding heavy loads;

- resistance to sudden changes in temperature.

The disadvantage is the large weight of the products, as well as the possibility of sparks, which in some areas is unacceptable. For example, when installed on a gas main, an explosion may occur. Cast iron products often become objects of theft, so additional protection against opening locks is required.

High-strength cast iron is distinguished by the presence of graphite in the alloy. It is used in places where heavy traffic occurs and rated loads exceed 250 kN.

Plastic hatches

One of the advantages of plastic sewer manholes is their low cost, since they can be made from recycled materials. Every year, the industry offers more and more durable models that are not inferior to metal ones.

Plastic can be given any color by adding pigment at the melting stage.Plastic models in private septic tanks and storm sewers are especially popular. They install polymer hatches in pedestrian areas without fear that they might be stolen - plastic is of no value to robbers.

Synthetic materials are not affected by temperature and do not fade under the influence of ultraviolet radiation. The appearance of the site will remain for a long time. If you do not exceed the load, then the plastic will last a long time.

The only drawback is that such materials are not suitable for high-traffic motorways, as they are quickly destroyed.

Polymer sand mixture

It is a combination of sand - 70% and plastic waste - 30%. The quality of the finished mixture depends on the purity of the raw material - the absence of technical oils in it. After grinding and melting the components from the mixture, a product of any shape can be cast. After solidification acquires the following characteristics:

- not affected by aggressive liquids, therefore, it can be used in wells with household and industrial waste;

- resistant to low and high temperatures;

- weighs little;

- does not cause a spark, therefore the product is safe.

Hatches do not represent material value in comparison with cast iron or iron.

Due to the fragile component in the composition - sand - sewer manholes made of polymer sand mixtures do not withstand heavy loads. They are used in private septic tanks, green and pedestrian areas.

Composite hatches

The composite premix material is popular. The production is based on the use of nanomaterials, which allow good mixing of the components in the composite.

Premix contains:

- fiberglass;

- calcite;

- polyester resins;

- other additives.

The material is obtained by heating to 100 degrees, after which products of the desired shape are cast from it. Composite hatches can withstand loads of up to 40 tons, have light weight and excellent durability. They are not valuable for robbers, therefore they serve longer.

The price of a composite sewer manhole is quite high - this is the only drawback.

Rubber sewer manholes

Cast-iron structures can be replaced with high-strength reinforced rubber. Such material does not rust, does not crack. Specially prepared rubber is resistant to high and low temperatures, aggressive liquids.

Rubber caps are used in various systems - fire fighting, water supply and sanitation in the private and industrial sectors. Robbers do not touch them, so in public places such models are safe to install.

For a quality installation, it is necessary to prepare the base - pour it with concrete. The cover is mounted on one level with asphalt or soil.

Concrete and reinforced concrete

For the manufacture of concrete and reinforced concrete hatches, high-quality cement is used - resistant to moisture and mechanical stress. It is used in combination with concrete rings: after installing the top plate with a hole for the hatch. For convenience, metal handles are poured into concrete.

Advantage:

- low cost;

- weight - it is almost impossible to lift a heavy plate for children or adolescents;

- durability.

The disadvantages lie in the appearance of the product - it will not work to give concrete a certain color due to poor adhesion with dyes.

Installation and fixing

Light polymer or polymer sand hatches can be installed independently. Heavy cast iron or concrete structures will require the help of other people or equipment. On walkways, covers should be flush with the cover. If the hatch is placed on the flowerbed, it is better to raise it slightly above ground level so that dirt does not fall into the well.

DIY installation steps:

- First, the support ring is installed on a solid base - formwork. For accuracy, you must use the level. If the installation is made at a slope, then the design will eventually become unusable and collapse. A cement mortar is used to connect the concrete rings to the manhole support ring. When it has completely hardened, work can continue.

- The cover is mounted. How to do this depends on the model.

- The final stage is the filling of the blind area. It is done at a distance of 1.5 m from the center of the hatch. A cement mortar is used. So that the blind area has a neat appearance, the edges are fenced with brick or bending metal, the bottom is covered with sand and poured with concrete. When it freezes, the devices are removed.

After installing the sewer hatch, it can be decorated with artificial stone or covered with a layer of synthetic grass. Flower beds are sometimes arranged in the lids so that the vegetation hides the presence of a septic tank on the site.

It must be remembered that at any time, maintenance of the well may be necessary, so the top of the lid cannot be heavily cluttered.

Prices for various types of hatches

The cheapest will be products that can not be given a heavy load. These are hatches made of plastic or polymer-sand mixtures. Low cost, but higher performance features rubber. If we are talking about installing on a summer cottage or near a private house, then there is no need to overpay for cast iron products.

Composite materials and ductile iron are distinguished by a higher cost. These materials are selected if pressure will be applied to the hatch every day, for example, the sewer well is in the vehicle’s driving range. The price of a cast-iron sewer manhole is comparable to the cost of a synthetic material.

The cost of products also depends on the size - diameter and height of the cover.