Pipes of various diameters are one of the main elements of the sewer system. It is necessary to devote time to their study and selection. The term and the effectiveness of the operation of the system will depend on this. Pipes and fittings are made of materials that differ in technical characteristics.

Scope of sewer pipes

Various types of sewer pipes are used in internal and external systems. Distinguish them by color. The external sewer pipe is made of material painted in orange so that they can be seen during excavations during the repair. They are stronger and more durable than internal grays, since they are operated in extreme environmental conditions, they are exposed to temperature differences and mechanical stresses of the soil.

The inner pipes are gray or white. It is not recommended to use them for external drainage, because they have less load capacity and there is a risk of premature failure.

Black pipes are the middle link in technical specifications between internal and external communications. They have temperature limits - you can not transfer hot liquid.

Green sewer pipes are designed for drainage system. Sometimes sold with a geotextile filter. Drainage communications are pipes with openings. Through them, the liquid enters the filtration fields and goes into the ground.

Pipes for arranging internal and external sewage, stormwater and drainage systems can be combined and have a common well.

Types and arrangement of pipes for sewage

In addition to the direct parts, the system uses elements for connections - fittings. They are designed to go from a narrow section of a pipe to a wide one, turning, branching, connecting parts:

- coupling - has a sealing ring and is designed to connect straight sections;

- retraction - used in places where you need to observe a certain angle when branching;

- a crosspiece - allows you to connect several pipes of a smaller diameter at once;

- reduction - connects samples of different diameters;

- tee - combines several pipes of small diameter into one wide one - usually at the junction of internal and external sewers or at the exit from a specific site - a kitchen, a bathroom;

- stub - viewing unit.

- Coupling

- Reduction

- Spider

- Stub

- Challenge

- Tee

In addition to these devices, two-knee siphons and check valves are used. All components have different wall thickness and diameter.

By types distinguish:

- steel;

- cast iron;

- ceramic;

- plastic - PVC, polypropylene, fiberglass, polyethylene, HDPE;

- concrete.

Each type has its positive aspects, if you properly install and operate the product.

Production material

There are materials that are practically not used in everyday life, for example, black steel. The material is durable, but problematic in terms of installation. To equip the sewerage at the summer cottage, it will require the involvement of construction equipment and welding specialists, since there are no other connection methods for metal.

The advantage of black steel is that it withstands high temperatures and is resistant to aggressive substances. But such properties in a home sewer system are not useful, so there is no point in overpaying for them.

Ceramic pipes

Ceramics is a very durable material that is used in adverse conditions. If the groundwater level is close to the surface, then ceramic pipes do not face corrosion, unlike metal pipes. The material withstands chemicals. The diameter of the ceramic sewer pipe allows them to be used in areas with intensive drainage. The wall thickness makes it possible to lay the pipeline in areas of motorways with active traffic.

Disadvantages of ceramic communications and installation:

- the material is brittle, so cutting it is problematic, it can be damaged during loading;

- parts are made of small length, so installation is longer and labor-intensive;

- It does not tolerate low temperatures, so they need to be laid deeper or wrapped with insulation.

Thus, ceramics is not a practical material, although it has some advantages.

Plastic materials

Among modern polymers, one can distinguish especially popular varieties:

- PVC - polyvinyl chloride. Often used in internal and external home sewage systems. The inner walls are smooth and the fluid easily moves by gravity to the sump. Of the minuses - exposure to temperature extremes. It is allowed to use water, the temperature of which is not higher than 60 degrees, a short-term increase to 100 degrees is possible. There are light, medium and heavy PVC products that are used depending on the load on the site where communications are laid.

- Polyethylene. The temperature range is small: from - 40 to +40 degrees, which excludes the use of polyethylene communications where the working temperature of the effluents is higher. Most often, such pipes are laid in the ground or used for cold water supply. HDPE - low-pressure polyethylene - a more versatile material that is resistant to short-term pressure increases, can withstand high temperatures, is not deformed at the same time. Of the minuses, it is suitable only for underground installation, as it loses properties under the influence of ultraviolet radiation. Of all types of polyethylene, only cross-linked polyethylene can withstand high temperatures.

- Polypropylene. Has a declared service life of up to 100 years. Withstands aggressive environments and high temperatures, does not break during deformation. Of the minuses - increased sensitivity to ultraviolet and softness, which requires additional strengthening before laying in the ground.

One of the varieties of sewer pipes is corrugated. The inner surface is smooth, and the upper has a corrugated polyethylene lining. It is used in outdoor systems where increased strength is required. Corrugated pipes can be laid to a depth of 15 meters. The industry produces various product sizes and material combinations to improve technical specifications.

Concrete

Concrete communications have a high rate of environmental friendliness, but they are very difficult to install - you can not do without special equipment. A significant minus is the rough inner surface. In a home system, this will lead to fast sticking of waste to the walls and clogging. When loading and unloading with concrete or asbestos-cement pipes, you need to handle carefully, as they can be damaged. Reinforced concrete is stronger in this respect.

Cast iron

If you choose between steel and cast iron pipes, the advantage will be on the side of cast iron, because it is not subject to corrosion. Prices are higher, especially for a modified one, which is more ductile and durable - there is a low probability of cracking and spreading.

In domestic sewers, where a lot of fatty waste is produced, the rough inner walls of cast iron contribute to the buildup of dirt, so you will have to clean them more often.

The problem is created by the weight of the cast-iron structures; therefore, communications are mounted only with auxiliary equipment.

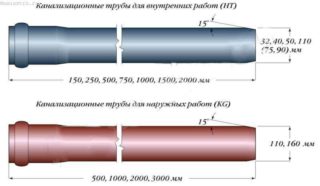

Pipe sizes

For internal wiring, the diameter is selected from 50 to 100 mm, depending on the type of plumbing. For sinks, showers and bathtubs, 50 mm is sufficient. The toilet is connected by a pipe of 100 - 110 mm. The same section for a common riser. In a private house in the basement, pipes with a diameter of 150 mm are installed through the transition fitting. At the exit from the house, the diameter should be no less than 150 mm in order to eliminate the risk of clogging at the junction of internal and external sewers.

Key selection criteria

When choosing sewer structures, it is necessary to rely on two indicators - wall thickness and pipe diameter. The strength of the trunk will depend on the thickness, and uninterrupted operation and the absence of blockages will depend on the diameter.

When choosing sewer structures, it is necessary to rely on two indicators - wall thickness and pipe diameter. The strength of the trunk will depend on the thickness, and uninterrupted operation and the absence of blockages will depend on the diameter.

For gravity systems, the wall thickness of the internal wiring should be at least 1.8 mm. With the depth of laying the outer line up to two meters in the soil, the walls of the products should be thicker - 3.9 mm. When laying up to 4 m - 4.9 mm, up to 6 m - 5.9 mm. The deeper the trunk lies, the greater the surface load.

Take into account the pressure in the pipeline. In gravity systems, it is less than with a running pump that pumps fluid. The pump is connected if it is not possible to comply with the necessary slope of the sewer.

Most often, for the arrangement of local sewage, PVC or polypropylene material is chosen. Fiberglass is popular, but a sewer pipe made of this material is more expensive, because it has a service life of about 100 years.

To clean your home system less often, it’s best to select materials with a smooth inner surface that grease and other debris do not stick to.

Cost of sewer pipes

You can overpay for sewer pipes if they are bought to supply drinking water to the house. For example, PVC and polyethylene are not suitable for this purpose, since they emit harmful substances, although a rational decision is made to drain drains.

The cost of steel pipes does not justify itself. They are not suitable for drinking water, and soon they will rust in the sewage system. Cast iron sewer is expensive and heavy, but reliable, especially if an alloy with magnesium is used.

In terms of price and quality, the best are polypropylene and fiberglass structures. They are the most durable and at the same time environmentally friendly. They are used both in the drinking water supply system and for the construction of sewers.