To install the sewer network, pipes and fittings are required - components. The effectiveness and duration of the system depends on the correct selection of these parts.

Materials of manufacture

Pipelines for sewage are made of cast iron, polyethylene, polypropylene, polyvinyl chloride, steel, asbestos cement and ceramics. Components are selected from the material used for the manufacture of pipe segments.

Most often, polypropylene, polyethylene and PVC elements are chosen. They are less durable compared to metal, but have the following properties:

- incombustibility;

- resistance to external factors;

- immunity to corrosion;

- resistance to aggressive chemicals.

Plastic parts do not react with acids and alkalis. Affordable price is also an advantage.

In second place in popularity is malleable cast iron. It can withstand any load and, unlike other ferrous metals, it does not rust. But such pipes weigh a lot, which complicates installation, and are prone to siltation. They are more often installed in enterprises where the issue of the strength of the trunk under high load is important. Pipelines from other materials are mounted extremely rarely.

If the sewage system is forced, it is important to choose the pressure elements of the line. They are also made of plastic or cast iron, but are designed for more pressure, because the possibility of a breakthrough should be completely excluded.

Varieties of components

The internal sewage system consists of pipes and fittings. When installing highways, fittings such as elbows, tees, and couplings are usually used. The former can have one or two sockets, they are used to combine different branches and on the corners of the pipeline. Tees are used to divert additional branches from the trunk. They are produced with an angle of inclination of 45, 65 and 90 degrees. The coupling is required when joining pipes of the same cross section.

The internal sewage system consists of pipes and fittings. When installing highways, fittings such as elbows, tees, and couplings are usually used. The former can have one or two sockets, they are used to combine different branches and on the corners of the pipeline. Tees are used to divert additional branches from the trunk. They are produced with an angle of inclination of 45, 65 and 90 degrees. The coupling is required when joining pipes of the same cross section.

Other elements for internal sewage may be needed:

- Reduction - for the transition between sewer pipes of various sections, as well as for articulation of cast iron and plastic products.

- Two-plane crosspiece - to make two branches at right angles to pipe segments with the same or different sections, tilt angles - 45 and 90 degrees.

- Single-plane crosspiece - for the device of two parallel branches with an angle of inclination of 45 and 90.

- Retraction - when creating turns in the laying of two parallel pipelines, angles of 30, 40 and 90 degrees.

- Compensation pipe - to eliminate damage by replacing the problem section of the line, which is cut out in advance.

- A cap is an element that blocks the transported drains when performing repairs or revisions.

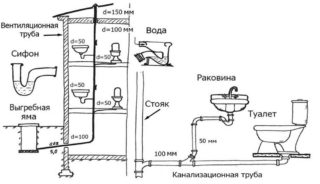

An aerator or sewer valve is used to block the exit of gases to the bathroom through the toilet as a result of rarefaction of air inside the fan pipe, due to which the water trap is pulled out of the siphon device. It is mounted on the upper riser end.

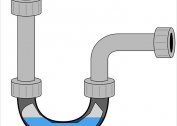

For installation of external sewage, a check valve is used. It is used to block the reverse of the circulating fluid and is mandatory installed on pipelines laid with an inclination of less than 2 cm. A two-knee siphon is also required, which combines two parallel pipe sections. The bending created at the junction prevents the return of sewer gases.

Sewer Fittings Sizes

To lay the internal sewage, pipes of such sizes (cross-section) will be needed:

- shower, sink, bidet, sink, bath - 40 mm;

- combined drain for shower, bath and sink - section 50 mm;

- toilet bowl and central riser - 110 mm;

- bends from the main riser - 60 mm.

To install external communications use pipe sections with a section of 160-200 mm. The dimensions of the plastic sewer pipes and the corresponding fittings must match. According to GOST, couplings are usually produced with a cross section of 110–400 mm and a length of 120–330 mm. The standard diameter of the bends is 110–400 mm, the distance between the sockets is 15–90 mm. 45-degree tees are made with a cross section of 110–400 mm, the length of the side sockets is 140–530 mm, and the height from the end part to the beginning of the socket ledge is 140–500 mm. The cross-section of the return valves is 110–250 mm, double-knee siphons 110–200 mm, lengths from 300 to 520 mm and from 510 to 820 mm, respectively.

Recommendations for choosing pipes and fittings

For reliable long-term and safe operation of the sewage system, follow these recommendations:

- Before purchasing pipe sections and fittings, draw up a project indicating all drain points and plumbing fixtures. It will help you find out what section and length pipes are needed and how many components are needed. The last indicator will depend on the number of turns and branches.

- Add a 10% margin to the calculated pipe length.

- If possible, equip the line with fittings of the same manufacturer as the pipe sections. Buy parts with exact match in size.

- Pipes for the internal and external piping should be sized appropriately so that too much sewer pressure does not lead to a pipe break.

The more shaped elements in the pipeline, the higher the likelihood of blockages. Simplify the geometry of the sewage system as much as possible, and place the sockets in such a way as to ensure free outflow of water.

Mounting Features

In order to ensure maximum density of the joining of elements and to avoid leaks, the assembly and connection of pipelines made of plastic is carried out in compliance with the following requirements:

In order to ensure maximum density of the joining of elements and to avoid leaks, the assembly and connection of pipelines made of plastic is carried out in compliance with the following requirements:

- Large-sized plastic parts are cut using a special tool - a pipe cutter. Instead, you can use a grinder or hacksaw.

- The slice is performed at right angles to the axis of the pipe, since it will not be possible to make a tight connection in the presence of a skew at the junction.

- The ends of the joined pipe segments are made as even as possible. The edge of the saw is subjected to sandpaper or a file.

- The joints of glued fitting elements are degreased first, then the glue is smeared and the parts are joined. The exposed glue is removed with a rag. Using fittings with a sealant, the surface of the joints is coated with silicone sealant.

- Details are not inserted all the way, but with a distance of 1 cm to create a compensation gap. To do this, make preliminary measurements and put a mark on the pipe segment to limit the depth of entry.

Avoid joints at an angle of 90 degrees, it is better to replace one knee at a right angle with two 45.

The price of pipe segments and fitting elements depends on the material, purpose and manufacturer. For example, pipe sections with a cross section of 50 mm and a length of 500 mm made of polypropylene from the Sinikon company are sold at a price of 63 rubles. The same part of the Politron brand can be bought for 41 rubles. The Hemkor pipe with similar dimensions, but from NPVH costs from 34 rubles.