Sewerage treatment plants (sewage treatment plants) is a set of technological equipment that allows wastewater to be cleaned to standard levels so that it can be discharged into a reservoir or city sewage without harm to the environment and human health. Perhaps their secondary use for the technical needs of industrial facilities.

Varieties of sewage treatment plants

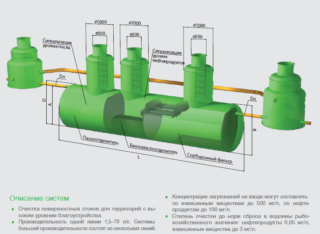

City-wide cleaning devices pass through a mixture of domestic, industrial and storm drains after rain or snow melt. Local (VOC) are being built at enterprises to eliminate pollution in effluents before dumping them into the collector network of the city or before reuse. An autonomous type of VOC is chosen for cleaning sewers in private homes.

The main types of treatment plants are:

- mechanical OSK;

- biological treatment systems;

- devices for oxygen enrichment of clarified waters;

- adsorbent filters;

- installations for ion exchange;

- electrochemical and physico-chemical blocks;

- disinfecting systems.

The cleaning equipment can include tanks where the filtered sludge is stored and processed.

Features of functioning

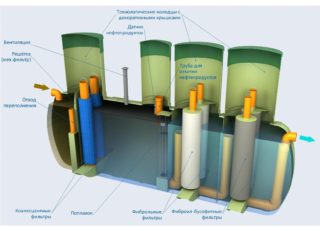

The scheme of the sewage treatment facilities (WWTP) is based on four stages:

- Mechanical Large fragments of suspensions and debris are eliminated with the help of primary sedimentation tanks, sand traps, grids that prevent the entry of debris and leaves.

- Biological After most of the water-insoluble impurities are removed and the effluents are clarified, the liquid for subsequent purification enters the aeration tank - a unit with extended aeration. It consists of two parts for aerobic and anaerobic cleansing. As a result, organic dirt breaks down, phosphate and nitrate compounds are eliminated. After this, the sludge goes into the tank, settles a second time and is divided into an active sludge substance and purified water.

- Tertiary treatment. It is carried out in self-washed sand filters or in modern membrane filtering devices. At this stage, the volume of suspensions decreases to 3 mg / L.

- Disinfection. It is carried out by treating the liquid with ultraviolet radiation with additional purging with air to increase efficiency.

Effluents after all stages of purification do not pose a danger to nature and can merge into a reservoir.

Types and principle of operation of stand-alone devices

This type of VOC is installed on personal plots. The main types of such sewage treatment facilities are septic tanks and filtration complexes.

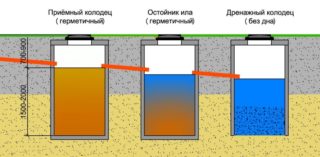

The principle of operation of simple sewage treatment plants of this type:

- From the sewage system, sewage is sent through a pipe to the first sump, where coarse and heavy contaminants settle.

- When the overflow level is reached, water flows into the second compartment, and large fractions remain in the first.

- Further purification of effluents is due to the work of anaerobic bacteria that contribute to the decomposition of mud residues into water and nitrites. Water is passed through filtering devices and purified up to 65 percent. The result of the work of microorganisms can be the appearance of an unpleasant odor.

- Then the liquid enters the irrigation dome - the infiltrator.After it passes one more filter - soil, the quality of purification reaches about 95 percent. This water can be watered plants in the garden or garden, as it is considered safe.

Most of these systems operate without the use of electrical energy. Non-volatility is one of the main advantages of autonomous installations.

The choice of the optimal system and design features

The selection of a home cleaning device is based on the following criteria:

The selection of a home cleaning device is based on the following criteria:

- the amount of water that is consumed per day, depending on the number of users;

- mode of use of the sewer system;

- characteristics of the climatic zone and soil;

- soil freezing depth.

When installing production VOCs, the location of the supply manifold and compressor devices, the possibility of placing the outlet of purified water, and the need for additional equipment are additionally taken into account. You will also need a free access for garbage trucks and special construction equipment.

The design of the construction should include all the operational characteristics of the system, sanitary standards and the legal framework.

SNiP regulation

Cleaning structures must comply with sanitary standards and requirements so that no problems arise in the future. The main documents that should be studied before the construction of the installation:

- clauses on “Sewerage of external networks and structures” are prescribed in SNiP 2.04.03-85;

- Clause 4.5, SanPiN 2.2.1 “Sanitary protection zone and protective sanitation of classifications of industrial facilities”, where the standards for the installation of facilities are described;

- FSUE NII VODGEO, which describes the rules of calculations during design.

Compliance with all sanitary and technical rules allows us to guarantee the quality of installation work and to avoid a variety of problems with organizations involved in monitoring.

System installation

The technology for the construction of a cleaning device involves the following steps:

The technology for the construction of a cleaning device involves the following steps:

- design development;

- assessment of the preparedness of the site for installation work;

- system installation;

- connection to communication lines;

- setup adjustment, regulation and tuning of automatic units.

A comprehensive analysis of the installation is carried out based on the structural characteristics of the structure: its performance, equipment, as well as taking into account the particular location of the installation.

Maintenance of treatment facilities

Professional and on-time maintenance of treatment plants allows for the efficient operation of equipment. Similar works involve:

Professional and on-time maintenance of treatment plants allows for the efficient operation of equipment. Similar works involve:

- removal of delayed water-insoluble impurities;

- identification of the volume of the formed sludge;

- oxygen testing;

- control by chemical and microbiological criteria;

- performance test of all blocks.

The main stage of VOC maintenance is the prevention of electrical equipment: devices for pumping air and pumps for pumping, ultraviolet units with disinfection radiation.

If we talk about autonomous installations, the main point of service is the pumping of solid sediments and sludge from the receiver. Such an operation is performed approximately every three years. After that, it is necessary to introduce anaerobic microorganisms into the compartment with brushes and fill the tank with water. To reduce the contamination of the device, you need:

- selection of the installation of the required volume and performance;

- updating the composition of microorganisms;

- periodic mixing of filter granules.

It is not recommended to pump out all sediment. About 20 percent must be left so that all microorganisms do not disappear.

Proper maintenance of the sewage treatment plant helps to extend its operation time and allows you to seek help from specialists less often.