Sewer wells - part of the system that transports sewage to the place of treatment or disposal. They are installed throughout the highway so that at any time it is possible to repair or replace a section of the pipe.

Current requirements for sewer wells

The main requirements are for the location of the sewer wells, their types, sizes. A well should also be equipped on a private site - this facilitates repairs that will have to be done sooner or later.

For central city sewage systems with pipe widths of up to 150 mm, inspection hatches are provided every 35 meters. If the pipes have a diameter of 200 mm, hatches are equipped every 50 m. In addition, the wells are installed in each section where the trunk turns, changes in its level, slope, branching or change in the diameter of the pipes. In such places, blockages most often occur, which must be eliminated mechanically.

Technical specifications and operating instructions are developed separately for each material of which the pipes are made.

The diameter of the inspection hatch depends on the diameter of the line:

- with a width of up to 150 mm the hatch must be at least 70 mm;

- 600 mm - diameter 1 m;

- 1200 mm - hatch diameter 2 m.

If the line is over 1500 mm, the inspection well should be about 3 m. This is necessary for high-quality repair of the pipeline, where usually several people work simultaneously.

Construction requirements include a sequence of actions, the selection of suitable materials, based on the characteristics of the soil, its mobility, depth and natural and climatic conditions.

The main types and arrangement of sewer hatches

Types of sewer wells are distinguished by the method of maintenance:

Types of sewer wells are distinguished by the method of maintenance:

- inspection - their diameter does not allow a person to descend inside, all work is carried out using tools from the surface of the earth, a plastic pipe with a diameter of up to 700 mm acts as a well;

- Serviced - a person can go down and carry out repair measures, the diameter of such hatches is from 1000 mm.

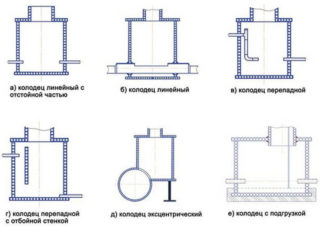

According to the functionality, they distinguish:

- Accumulation well. The volume depends on how many people live in the house. The function is to collect and distribute sewage. To facilitate the transportation of wastewater, a storage tank is installed at a low point in the site to avoid blockages along the sewage route. They are made of plastic, brick, reinforced concrete rings, concrete.

- Filtering. It performs the function of removing the liquid fraction through the open bottom. It is usually installed after the storage tank - the settled liquid without solid particles flows into it. The presence of a filtering well increases the time intervals between the pumping of sewage. In the second septic tank there may be bacteria that help break down the organic component of the effluent.

- Lookout. Designed to assess the state of sewage in the city or on its own site. Over a large area, it is recommended to put several hatches in those places where the pipe changes diameter, turns, changes the angle of inclination or before tapping into a centralized system.

- Turning. Install in places where the system branches into several directions or turns. If the sewage system becomes clogged, most likely it will happen in this area.

- The overflow well of the sewage system is installed in the case when the complex terrain does not allow you to correctly set the angle of inclination of the highway. The differential hatch is distinguished by the presence of a vertical pipe, for which an angle of 45 degrees is set.

Inspection hatches are used for any type of wastewater - domestic, industrial or natural - rain, melt snow. The material of the pipes is chosen so that they withstand the temperature and chemical composition of the transported liquids.

Wells - components

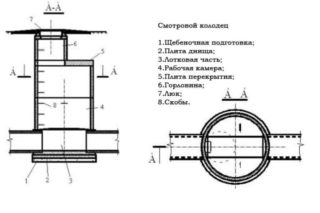

The main parts that are present in the inspection wells:

The main parts that are present in the inspection wells:

- a working chamber of sufficient size so that it can fit the person who serves this system;

- neck;

- hatch that is made of concrete or plastic;

- tray;

- the base of a concrete slab laid on a layer of crushed stone.

The working chamber is equipped with iron brackets (steps) along which the workers descend inward. The layout of the sewer well device depends on the functions of the line. If this is a home system, its scheme will be simplified. If industrial, with various branches and slopes, the scheme will need a more complex and functional.

Materials for the manufacture of wells

Previously, the main material for the construction of inspection wells was brick. It was laid out and fastened with cement mortar. Now in some old cities there are still examples of such hatches. The arrangement took time and effort. The tightness of masonry deteriorates over time and odor can spread.

Over time, the brick began to be replaced with concrete rings. Such material lasts longer and does not allow liquid and odors to pass through. Mount it faster: you need to dig a pit of the right size and apply the technique to install the rings. To seal the gap between the components, cement is used.

Polypropylene is the material of the future when arranging inspection wells. Its chemical and physical properties allow it to work at high temperatures of liquids - the material softens at a temperature of +140 degrees. It is not susceptible to corrosion. Polypropylene can be affected by ultraviolet radiation, but since the sewage system is mounted underground, this does not affect the quality of the pipes.

Polypropylene ranks second in terms of sales in the world. Old sewer lines are gradually being replaced by plastic products.

Polyethylene is a durable heat-resistant material. It has several varieties. For example, cross-linked or ultra-high molecular weight polyethylene is designed to work in extreme conditions - in severe frosts, with a high coefficient of friction from the inside, under shock loading, for working with particularly aggressive fluids that flow from industrial facilities to their storage location.

Fiberglass is another polymer material that has a degree of strength comparable to steel products. At the same time, fiberglass products are lighter, do not corrode, are able to transport liquids that aggressively affect metal or other types of plastic. The main component is quartz fiber.

Often corrugated pipes are used for the installation of inspection wells. They have a high degree of strength due to protrusions around the circumference, withstand loads in the form of soil movement, if such phenomena are characteristic of a given area.

Design and installation steps

Before the start of construction work, preliminary activities are carried out:

- determination of the highest and lowest levels of the site;

- marking the territory for digging a pit and trenches for pipes;

- transplanting plants that are on the way of the highway;

- cleaning buildings that interfere with work.

Work begins with digging a pit and arranging the walls. Further:

- the bottom is being prepared - poured with bitumen or covered with gravel;

- the installation of concrete rings or a plastic pipe of the required diameter is carried out - it depends on whether it will be a serviced or inspected well;

- walls and joints of concrete rings are rubbed with bitumen or cement mortar;

- when connecting the inlet and outlet pipes, the joints are also smeared with hot bitumen, if plastic can be melted or welding can be used, this is an easier way to seal the structure.

At the end, a hatch made of concrete or polymer material is installed. Plastic models are more suitable for a private house because of their aesthetic appearance.

Manhole Maintenance

Wells - both urban and private - require regular inspection. Repair or cleaning is necessary if the bottom is very silty and an unpleasant odor is heard from the hatch. After the winter period, engineering networks often fail.

Usually, service specialists are called in to carry out repair work, who carried out the installation of the entire sewer system. With your own hands, cleaning the inspection well can be done with tools and experience.

In private areas, accumulation of garbage in a well is unlikely, but in the city this is the biggest problem, especially after heavy rains - the mine shafts are clogged with household waste and plastic.

With improper installation of the sewage system, repair work will become an integral part of life, so their construction must be trusted by professionals.

The price of a well under a sewer is the sum of the cost of the materials themselves, as well as the installation work. The most reliable and easiest to install are plastic shafts for wells. If desired, you can choose reinforced structures at a more expensive price, or ordinary ones to inspect the condition of the pipes. For a summer residence or a country house, it is recommended to choose polymeric materials and plastic hatches, so as not to spoil the appearance of the site.