Revision installations are equipped so that the distance from the earth's surface to the bottom of the well exceeds a meter. In order to audit utility pipelines and troubleshoot, the wizard must go down. To do this, he will need a ladder. It should be strong, light and securely attached to the concrete base of the well. Specialized sewers and gutters meet these requirements. They are designed to simplify access to pipelines at various levels.

Sewer ladder requirements

Work in the audit wells is harmful and dangerous. The equipment has quite stringent requirements.

Qualities that must be possessed by devices for lowering into sewer and drainage wells:

- Resistance to moisture. In places of the sewerage highways the increased level of humidity. Even with temporary use of staircases, water destructively affects their surfaces. The materials from which the stairs are made must be corrosion resistant.

- Strength. By itself, falling into a well shaft threatens injuries, and if it is also filled with sewage, the danger doubles.

- Reliable fastening on a side of audit. Stairs are more often hinged, since the bottom of sewers is hidden from the eyes by sewage, it can turn out to be uneven and slippery. It is much more reliable to strengthen structures with the help of special hooks.

An important requirement is ease of use. Massive, heavy and impractical structures are not suitable for revision. Light, mobile and versatile needed.

Varieties and design features

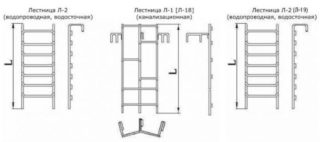

According to GOST, metal staircases for the needs of the sewage system are of two types. These are sewer stairs marked KL 1 and gutters - VL 2. The length of both can be from 1 to 6 m, the diameter of the elements is from 20 to 28 mm. The interval between the steps is half a meter. Weight varies: for KL 1 models it varies in the range from 25 to 103 kg, and for VL 2 it varies from 15 to 87 kg. This is due to design features: KL 1 - the structure is double, with equal spans on one side and different spans on the other. This allows you to get to the most remote sections of the pipeline.

According to GOST, metal staircases for the needs of the sewage system are of two types. These are sewer stairs marked KL 1 and gutters - VL 2. The length of both can be from 1 to 6 m, the diameter of the elements is from 20 to 28 mm. The interval between the steps is half a meter. Weight varies: for KL 1 models it varies in the range from 25 to 103 kg, and for VL 2 it varies from 15 to 87 kg. This is due to design features: KL 1 - the structure is double, with equal spans on one side and different spans on the other. This allows you to get to the most remote sections of the pipeline.

The upper parts of the stairs are equipped with reliable hooks that firmly fix them on the well neck. When the master descends into the collector, the design does not swing.

Workshops for the manufacture of stairs are guided by state standards, but if you need a product that is suitable for certain conditions, specialists are ready to fulfill the order according to the drawings. In shallow wells, special brackets are often used, fastened with fixing elements in the ring of the upper plate.

In addition to standard ladders, home-made rope structures are also used for descent into observation tanks. Their advantages in mobility and cheapness: you can create a product with your own hands. The loops are knitted at a distance of 40 cm, and hooks or another device for holding the stairs is attached to the pole. Such options do not take up space during storage and weigh very little. Really adjust their length. The disadvantage is that if the ropes rot, the user risks health and even life.

Production material

Standard staircase structures - KL 1 and VL 2 are created from smooth reinforcement made of high-quality stainless steel.Reinforcing rods are practically not susceptible to corrosion, resistant to stress and very durable thanks to professional welding.

Analogues of steel plants are fiberglass products. This material is distinguished by such positive qualities:

- resistance to moisture and aggressive liquids;

- dielectric properties, which is important when working near electrical wires;

- strength and lightness.

Fiberglass staircase manufacturers promise their long life.

Rope products are made of cotton or synthetic fibers (nylon, polyester). The rope in cross section should be more than 10 mm. The steps are made of thick plastic, stainless steel and even polished shovel cuttings.

When working in inspection wells, the use of equipment made of wood or iron without anti-corrosion coating is not allowed. Under the influence of moisture, these materials are quickly destroyed, which increases the risk of injuries and emergency situations.

Homemade stairs are attractive because they cost almost nothing. But those who do not like to take risks prefer manufacturing products with reliable fasteners - durable and withstanding heavy loads.