The obvious advantages of polymers lead to an ever-increasing proportion of plastic pipes in sewage systems. What materials are used in their production and how to make the right choice?

Where are plastic sewer pipes used?

In place of cast iron, steel, asbestos and concrete, which provided the needs of communication systems in the last century, came plastic of various modifications. In the external and internal drainage systems, waste channels, pipes made of polymer are successfully used.

Features of the composition of the plastic determine the operating conditions and scope of the pipe. It can be both gravity systems and pressure systems with a pressure of up to 10 atm.

Low hydraulic resistance, durability, resistance to chemical attack, easy installation and transportation make pipes of all types of plastic very attractive for developers.

Types of pipes and differences in application

Installation of sewer hydraulic systems involves the use of pipes from the following materials:

Installation of sewer hydraulic systems involves the use of pipes from the following materials:

- polyvinyl chloride (PVC);

- polypropylene (PPL);

- polyethylene (LDPE or HDPE).

In the construction of a modern housing stock, PVC pipes with a continuous inner wall were most widely used. They have a monolithic (single layer) or three-layer construction. In terms of ring stiffness SN there are five categories: 2, 4, 8, 16 or 32 kN / m2. Accordingly, the thinner the wall, the lower the stiffness indicator, which means that the pipe can withstand less load.

To facilitate stiffness control, the products have a different color. SN2 and SN4 are gray and are used only indoors, in boxes, trays and gates. The wall thickness is 2.7 mm.

Orange SN8 pipes (three-layer) have a wall of 3.7 mm and are intended for use outside buildings, can be laid in trenches, and can withstand significant mechanical stress.

White color indicates that the pipe wall has a thickness of 3.4 mm. This is a three-layer design with increased noise absorption.

Polypropylene has greater elasticity, is stable to temperatures up to 70 ° C and can withstand short-term exposure (no more than 60 seconds) 90 ° C.

When transporting and installing at low temperatures, PPL pipes better withstand shock loads.

Low pressure polyethylene (HDPE) is characterized by high strength, it is used in pressure drainage systems. Able to carry pressure up to 10 atm. But there is a limitation on the operating temperature (up to + 60 ° C). With prolonged exposure to hot water, it deforms.

It is an elastic material with a high yield strength. It responds to a longitudinal tensile load by lengthening rather than fracture.

Spiral pipes are made of polymerized ethylene with diameters up to 1600 mm. At the same time, the inner surface is smooth so as not to increase the hydraulic resistance. This two-layer design significantly extends the throughput of sewage.

Varieties of forms and compounds

One of the main advantages of plastic pipelines is its simple installation. This is possible thanks to a wide selection of shapes, sizes and standardization of compounds.

One of the main advantages of plastic pipelines is its simple installation. This is possible thanks to a wide selection of shapes, sizes and standardization of compounds.

The main elements of engineering structures for drainage:

- a pipe with a diameter of 32 mm to 200 mm;

- tee;

- knee with different angles of rotation;

- coupling;

- revision clutch;

- transition to another diameter;

- stub.

All engineering tasks that arise during the operation of the system are solved by installing the appropriate components.

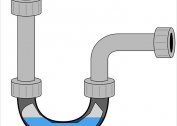

For PVC and PPL products, detachable joints are characteristic, providing reuse of structural elements. The bell is equipped with a special sealing rubber, which, when properly installed, guarantees a tight connection over the entire life cycle (guaranteed 50 years).

Polyethylene pipes are connected in one of three ways:

- with rubber seal;

- glue;

- welded.

In the welded method, the material is heated and, as a result of the diffusion of the areas subject to thermal effects, a strong connection is created. This is an integral way.

Standard sizes

For household sewage 3 standard sizes are used: 32, 50 and 110 mm. Such diameters make it possible to ensure wastewater in residential premises. For each plumbing unit, there is a recommended diameter of communications.

For household sewage 3 standard sizes are used: 32, 50 and 110 mm. Such diameters make it possible to ensure wastewater in residential premises. For each plumbing unit, there is a recommended diameter of communications.

Washing, dishwashers are connected to the system through a diameter of 32 mm. Washbasin, sink, bathtub, shower stall - 50 mm. Toilet bowl - 110 mm. With this arrangement, the pipe cross section fully copes with the assigned load.

The main channels can be assembled on the basis of pipes of a larger cross section, depending on the design operating conditions.

Features of installation and operation

Installation of detachable structures based on PVC or PPL is simple, due to the low weight of the products. Installation of pipes, assembly of all elements should be carried out in strict accordance with the project. It is important to observe the angle of inclination of the pipe to ensure a natural flow of liquid. The smaller the diameter, the greater the slope. For a cross section of 50 mm, the slope on each meter should be 30 mm, and for a 110 mm pipe, a 20 mm slope is sufficient.

Installation of detachable structures based on PVC or PPL is simple, due to the low weight of the products. Installation of pipes, assembly of all elements should be carried out in strict accordance with the project. It is important to observe the angle of inclination of the pipe to ensure a natural flow of liquid. The smaller the diameter, the greater the slope. For a cross section of 50 mm, the slope on each meter should be 30 mm, and for a 110 mm pipe, a 20 mm slope is sufficient.

For polyethylene products, it is important to remember the coefficient of thermal expansion. During installation, compensation gaps should be left so that expansion does not lead to pipe deformation.

When organizing an external sewage system, it is necessary to exclude freezing of the structure in the winter.

If a polyethylene pipe loyally reacts to freezing and restores its shape after defrosting, then PVC can get cracking and depressurization. It is important to prevent freezing temperatures in the system.

When choosing material for utilities, the design operating conditions should be taken into account. In standard living conditions, PVC pipes cope with water disposal, the most affordable. If there are no special conditions - this is the perfect solution.