Sealing concrete rings for sewage is one of the main requirements for the construction of structures for collecting sewage and sewage. The main task of concrete tanks is not to let pollution pass through technological joints and not to infect the soil around the well, as well as groundwater.

Methods of waterproofing sewer wells

There are two main technologies that differ from each other by the types of joining of reinforced concrete rings. The latest manufacturers produce two types:

- with flat ends;

- ends with chamfers in the form of a connecting lock.

It is easiest to seal the concrete rings of the second type. They are interconnected by a castle. The upper part of the rings is a chamfer inner, the lower part of the chamfer external. When connecting two rings, the chamfers enter each other, forming a tight joint. Between the elements of the locking connection, an additional material is laid, which, when compressed under the weight of the upper ring, is flattened, filling with itself the entire joint space.

As a sealing material, hemp or other fibers treated with technical oil are used. Increasingly trying on a rubber tourniquet or foamed polymer in the form of a cylinder of small diameter. Reinforced concrete rings with a flat end are sealed differently. Joints must be covered both from the outside and from the inside.

Joint sealing materials

The market offers a large number of materials with which you can process the joints of concrete rings for sewage. They differ from each other in composition and method of application.

The market offers a large number of materials with which you can process the joints of concrete rings for sewage. They differ from each other in composition and method of application.

Previously, the joints were covered with a cement-sand mixture, sealed with water. Such a putty did not last long, especially from the inside of the well, because the solution was subjected to active pressure from the sewer. Therefore, a small amount of water glass was added to it.

Such a solution dries quickly, so it is recommended to pre-prepare the joint. The volume of the finished mixture should correspond to the speed of operations. You need an amount that can be used within 10-15 minutes. The material is applied with an ordinary spatula.

The deeper and wider the gap at the junction of concrete rings, the thicker it is necessary to knead the sealant. And vice versa: the smaller the gap, the thinner the repair mass should be.

The second type of material that is used to seal joints is water seals. These are self-expanding mixtures which, when solidified, form a solid substance. It will not crack for a long time. Water seals on the market are represented by a large assortment from different manufacturers. The most popular are HydroStop, Peneplag, Waterplag and others.

The benefits of hydraulic seals include:

- resistance to temperature extremes;

- neutrality to acids, salts and alkalis;

- long term of operation.

The downside is the high price. But even this does not stop the owners of autonomous sewer networks using precast wells made of reinforced concrete rings. The high quality of the final result in this case justifies the construction costs.

Waterproofing concrete wells

The concrete structure must be treated with protective materials in order to increase the waterproofing characteristics. Therefore, the concrete structure is waterproofed externally and internally.

For waterproofing sewer wells from the inside, only plastering materials are used.The most popular is mastic based on a bitumen-polymer mixture. This is a semi-liquid material that is applied to the inner surfaces of a concrete well with brushes and rollers. Material Advantages:

- high strength of the applied layer;

- resistance to acids, alkalis and salts, household chemicals and other types of pollution;

- ease of application;

- low price;

- does not require thorough surface preparation.

The only requirement is to apply the mastic in two or three layers. In this case, each subsequent layer is applied after the previous one dries. Depending on the air temperature, it can take 3 to 8 hours to dry.

Bitumen-polymer mastics can also waterproof the external planes of wells. But more often they use the combined version: they use mastic and roll or membrane protection. As the latter, ruberoid or special membranes are laid on the rings, based on fiberglass, treated on both sides with a mixture of bitumen and polymer. Membrane material is many times better than roofing material.

Rules for waterproofing

For the combined method of waterproofing, it is necessary to prepare a well: close the joints between the rings, clean the surfaces from dust and dirt.

The sequence of the remaining operations:

- coat concrete rings for sewage installed on top of each other with mastic;

- until it dries, lay rolls of waterproofing material around the perimeter of the structure;

- laying is carried out from the bottom up so that the upper strips overlap the lower ones with an overlap of 10-15 cm;

- on the laid roofing material apply another layer of mastic;

- stack strips of waterproofing material in the vertical direction, taking into account the overlap of its edges within 10-15 cm;

- apply another layer of mastic;

- when it dries, fill the soil between the walls of the well and the walls of the pit.

The first layer of waterproofing roll must be laid so that the joints of the strips do not fall on the joints of the rings. This will provide a high degree of waterproofing.

Input sealing

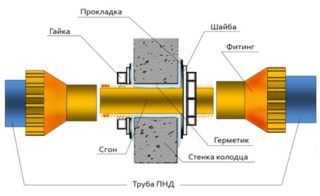

The inlet is the place where the sewer pipe enters the well of reinforced concrete rings. For this, a hole is made in one of them, usually the top one. It should be slightly larger than the diameter of the sewer pipe.

The main task is to introduce the pipe into the well and fix it firmly so that it does not hang in the hole. For this, a cement-sand mortar is usually used. In order for the latter to last longer and not crack during operation, a liquid plasticizer is added to its composition.

The second option is to fill the input with hot bitumen. Not the best way, because under the influence of temperature changes, bitumen cracks and flakes. But this is the cheapest method. In the requirements of SNiP for the arrangement of trays in sewer wells this technology is not taken into account.

The third option is to use the finished device: two steel disks with a hole inside, the diameter of which is slightly larger than the diameter of the sewer pipe. Between the discs there is a sleeve into which pipes are inserted. First, a sleeve is inserted into the hole in the concrete ring. One disc is put on the pipe. Then they put it through the sleeve, then put on the second disk. Then both discs are pulled together by four bolts or studs.

No matter how reliable the input is in terms of sealing, it is exposed to the negative effects of groundwater. Therefore, it is recommended to make a drainage layer around the sewer pipe. This is a bulk material of different fractions. It is covered in turn, for example, first sand, then crushed stone, or expanded clay first, and then clay is laid.