A high-quality drainage system allows you to drain the soil on the site and thereby maintain the integrity of the stone buildings. Important elements of communication are wells - viewing, turning, overflow, revision. They are mounted from prefabricated concrete rings or plastic tanks. However, PVC or PET pipe for a drainage well can be useful no worse than ready-made containers.

Types and arrangement of drainage wells

All wells of the drainage system are classified by purpose:

- Revision. Designed to assess the state of all communication. The viewing shaft must be large enough to allow a person to go down if repairs are necessary. More often, the revision is mounted on long sections of the system (from 10 meters) or on its corners.

- Overflow. It is mounted if the drainage system is arranged on a difficult terrain and the master is unable to observe its smooth slope in specific areas of the site. It has a sealed bottom.

- Turning. A kind of revision well, designed to make sharp bends in the system.

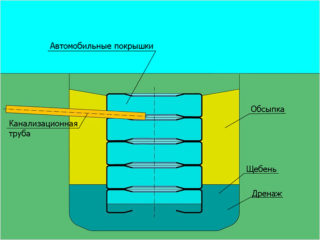

- Absorption (drainage). It is often called filtering. As a rule, it is installed if it is not possible to discharge the accumulated moisture into the city highway. The absorption well is the end point of water diversion from the site and is located in its lowest part. The filter shaft does not have a sealed bottom. Instead, they lay a drainage pillow of crushed stone and pebbles.

- Cumulative (collector septic tank). This is a tank with a sealed bottom for collecting rainwater. Subsequently, the liquid is either discharged by a pump into the nearest body of water / ravine, or used for household purposes (irrigation, watering).

When constructing a drainage well for a septic tank, you can use not only store items in the form of concrete rings or corrugated pipes, but also improvised tools such as rubber tires, plastic barrels.

Production material

For the manufacture of drainage system wells, two popular types of materials are used:

- Plastic. The polymer has a low weight, which is convenient when installing the system in the country with your own hands. In addition, plastic (polyethylene, polypropylene) is resistant to aggressive environments, inert to temperature extremes. And special rings in the corrugation of the polymer pipe play the role of stiffeners. That is, such a shaft is well resistant to seasonal swings and prone to linear tension. It is worth considering that working with plastic is easier when forming holes for drains. Yes, and serves as a polymer for 50 years or more.

- Concrete. Strong, strong and durable material. A well of concrete rings, even in very heaving soil, is firmly fixed. Due to the fact that the tank is assembled from individual elements, it is possible to mount shafts of different heights. Concrete serves no less than plastic. But when installing the well, it is necessary to use special equipment, since the mass of the rings is impressive.

You can do it yourself if you just pour a concrete shaft from the prepared solution into a specially prepared formwork. After the solution dries, it is removed and a durable, reliable well is obtained.

When careless work with concrete rings, you can disrupt the structure of the material. Concrete is able to crack under strong mechanical stress.

Criterias of choice

Choose the type of well according to the following criteria:

- Dimensions For many owners, the weight, length and cross section of the shaft matter.

- Technical characteristics of the material: durability, resistance to corrosion and aggressive environments, fracture and tensile strength.

- Cost. For many masters, this parameter is important, since the device of an extended drainage system can cost a pretty penny.

Often, in order to save money, owners of summer cottages decide to mount a drainage well of tires or polymer containers with their own hands. But the tightness of such a tank remains in question, since it is difficult to achieve the absolute integrity of the mine. Over time, it will still pass underground water, and the tires will deform under the influence of heaving soil.

Self-assembly of drainage wells

If the master decided to make a drainage well from an iron barrel with his own hands, it is important to consider that the metal will rust and eventually become unusable. From improvised materials it is better to use a plastic container or rubber car tires. The sequence of work in this case will look like this:

- Prepare a pit for the installation of a well. Its depth should exceed the height of the finished tank by 30 cm. The cross section should be more than 40 cm. The distance along the edges will be used for backfilling.

- The bottom of the pit is carefully tamped and a sand pillow 30 cm thick is laid in it. The sand is slightly moistened and well compacted.

- In the barrel at a distance of 30-40 cm from its bottom form partubki for drains.

- A barrel is installed in the pit, pipes are connected to it and filled to the top with water. Only when the tank is full can it be carried out circular filling with soil and gravel. Otherwise, the barrel will burst under soil pressure.

- Falling asleep around the earth, you need to ram it well.

If the well will be built from a corrugated pipe, it is necessary to first cut it in height and buy an additional bottom / manhole cover. In the corrugated pipe, holes are also made for nozzles into which drains can be supplied.

Installation of a well from tires

You can mount the shaft drainage system of rubber tires. Here the work will look like this:

You can mount the shaft drainage system of rubber tires. Here the work will look like this:

- Dig a hole of the desired depth and diameter.

- The bottom is well rammed and covered with a layer of sand.

- Alternately set one on one tire, smearing the edges of each subsequent bitumen mastic. It forms a protective sealed layer.

- The bottom of the well from the tires is poured with concrete mortar to form a completely solid tank.

- After the concrete dries, the mine is covered with soil in a circle.

For the construction of a drainage mine from tires, it is important to use only whole elements, otherwise groundwater will ooze into the well during the rainy and melting seasons.

The device of a concrete well from rings

In working with concrete rings, the procedure is slightly different. Here, the installation sequence looks like this:

In working with concrete rings, the procedure is slightly different. Here, the installation sequence looks like this:

- Under the installation of rings dig a hole of the desired diameter.

- As soon as the pit is ready for the first ring, it is set according to the level.

- Continue to dig the soil until the first element is lowered and free up space for the second. In this sequence, the required number of well rings is set.

- Joints of elements are coated with bituminous mastic, and all rings must be fastened together with special metal (steel) brackets. Otherwise, the soil may shift them over time, which will lead to depressurization of the mine.

- The bottom of the mine is rammed and covered with a sand cushion. Fittings are laid on top and concrete mortar is poured.

- After the bottom dries with the help of special crowns, holes for drainage are cut out in the ring from the inside of the shaft.

If you need a filter well, instead of a concrete bottom, a pillow is made of sand, fine gravel and gravel. All loose lay in layers of 20 cm each. The top layer is broken brick or river stone.

All drainage wells should be checked periodically for leaks.Properly mounted shafts serve from 40 years or more.