To account for gas consumption in private homes and at enterprises, a flow meter is installed. The device of the gas meter may be different. The difference in design does not affect the accuracy of measurements. But this affects the duration, reliability and features of the repair of the device.

The need for a gas meter

Federal Law No. 261 “On Energy Supply” obliges all owners of private houses and apartments to install a suitable gas meter in their homes. Installation is at the expense of the consumer. An exception is some categories of citizens: in this case, flow meters are mounted for free.

Installing devices is required. If the homeowner refuses to voluntarily install the flowmeter, the gas service employee has the right to do this by force. Otherwise, Gorgaz has the right to sue for obstruction of maintenance. In case of a positive court decision, the owner is obligated to pay the installation of the meter and a fine.

In fact, the terms of mandatory equipment by flow meters have been extended several times. There are not enough accounting tools and specialists; the queues for installing the flowmeter are huge. This allows many owners of private homes to ignore government demands.

The first step in the installation process is to apply to the local gas service department. If the owner does not file it, no sanctions can be applied to it. And since there is a large queue of those who are already waiting for the installation, Gorgaz temporarily ignores people evading the installation.

If the apartment has only 1 gas appliance - a stove, and gas is consumed only for cooking, it is allowed not to install a flow meter.

Varieties of gas meters

The gas meter measures the gas flow. The device is built into the gas circuit through which energy is supplied to the home. In a private house or enterprise, the device is mounted on the street - in a special cabinet under a canopy. In an apartment building, the flow meter is installed directly in the room.

The gas meter device depends on many facts: registration measurement mechanisms, power, purpose, throughput. The main consider 2 categories:

- Mechanical - gas flows through the pipe at a certain speed, depending on pressure. Its flow drives the transmission mechanism to the counting device.

- Electronic - sensors determine the volume of gas being transported and send corresponding pulses. The number of pulses is recorded and converted into the flow meter. Electronic models are equipped with an LCD display.

Each species has its own advantages and disadvantages. Mechanical models are easier to maintain, independent of electricity. Electronic more accurately and longer.

By design, accounting funds are divided into 5 groups.

Membrane

A diaphragm or membrane flow meter is most often found in everyday life. The device is easy to maintain, designed to measure small and medium volumes of gas.

A diaphragm or membrane flow meter is most often found in everyday life. The device is easy to maintain, designed to measure small and medium volumes of gas.

Advantages of membrane arrangement:

- a working life of more than 20 years is important, since the replacement of a spent meter is done at the expense of the consumer;

- large inter-check interval - 10 years;

- may work with insufficiently purified methane;

- low price.

Disadvantages:

- large sizes - in a cramped kitchen it is difficult to find a place for him;

- the device is noisy, and the greater the flow rate, the stronger the noise emitted.

The design is complex but reliable.Several sensitive membranes are associated with a system of channels and valves. When gas enters the meter, it fills the first chamber, after which the valve opens and passes gas into the second. The cycle is constantly repeated while gas is flowing through the pipe. Since the volume of the chamber is known, it is not difficult to count the number of openings in the volume of gas passed through the meter. Valves are controlled by transmitting force through a crank mechanism.

Rotational

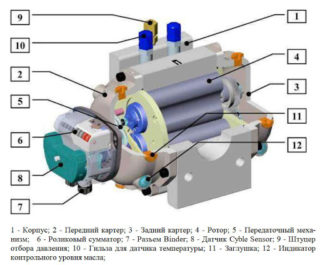

A kind of mechanical models. They are used in everyday life, in boiler rooms, in small and medium enterprises. They are independent of electricity, reliable, easily tolerate short-term loads.

The principle of operation is as follows: 2 eight-shaped rotors rotate in the housing, rolling around on the side surfaces. The first is connected with the transmission mechanism, the second - with the counting. The rotors rotate due to the difference in gas pressure that occurs when entering through the inlet pipe and the output through the outlet.

The accuracy of the measurement depends on the ease of movement of the rotors. When inspecting the counter, this parameter is carefully evaluated.

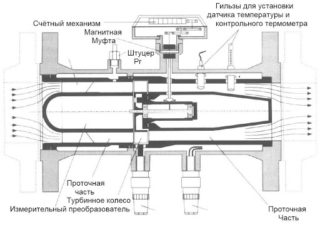

Turbine

More complex in design and include a turbine with rotary supports, a jet rectifier and a pump assembly. The latter serves rotation bearings. Depending on the pressure, the turbine rotates at different speeds. The number of revolutions is fixed by the counting mechanism.

A mechanical device can be automated. In this case, accounting control is performed by a computing device.

The turbine meter is reliable, easy to maintain, and creates little noise during operation. Used in enterprises. Disadvantage: the accuracy of the measurement depends on the stability and continuity of the flow. In pulsating mode, the measurement error increases markedly.

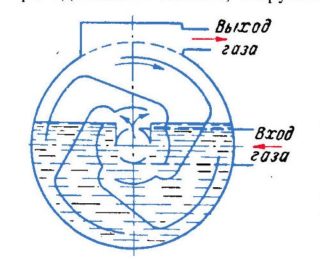

Drum

Such a counter works on the principle of crowding out. In the gate fluid - water, oil - the drum rotates under the action of pressure. In this case, 4 measuring chambers are filled and emptied. The gas volume in this case is measured directly. A thorough calibration of the cameras ensures a very high measurement accuracy.

The drum counter does not depend on temperature or the degree of gas purification.

Devices are used in places where high accuracy is most important: in factory laboratories, in institutes.

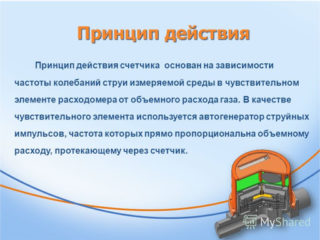

Whirlwind

They are based on the creation of vortex motion in a stream of gas, steam or liquid. In the pipe through which the gas is supplied, a trapezoidal flow body and sensors are installed to fix the magnitude of the appearing turbulence. The pair of sensors provides higher measurement accuracy and is insensitive to vibration and acoustic noise.

Vortex gas meters are designed to work in pipes with a diameter of 50 to 500 mm at a pressure of up to 30 MPa and a temperature of -60 to +500 C.

Device and principle of operation

The principle of operation of any gas meter depends on the device and method of measurement:

The principle of operation of any gas meter depends on the device and method of measurement:

- The diaphragm flowmeter is divided into 2 or more chambers. Each is connected to a valve mechanism, and a counter is connected to the shaft of the latter.

- Rotational is similar. Here mechanical energy is created by rotating rotors.

- in the turbine, the turbine acts as a working fluid.

Although the devices themselves are mechanical, the counting device in modern models is a real computer system.

Counter circuit

The general scheme is as follows:

- The working fluid or mechanism, placed in the gas stream, does some mechanical work: the rotor rotates, the chambers are filled.

- The mechanical work is fixed in some way: the counter registers the number of revolutions, the cameras measure the volume of gas, the rotation energy is converted into electrical signals.

- Sensors transmit data to the measuring device. The latter is usually placed on the pipe.

The design may include additional devices.For example, a temperature compensator avoids errors when the temperature rises.

The principle of operation of the electronic gas meter

Smart gas meters are equipped with electronic measuring modules. Instruments are fully automated and usually independent of electricity. The electronics are powered by a rechargeable battery.

The electronic module provides several advantages:

- Greater measurement accuracy - the conversion of mechanical energy into electrical energy is faster and more accurate, sensor sensors allow you to take into account changes in pressure at different gas temperatures and more.

- Counters are equipped with LCD displays. They are more convenient and transmit more information to the user.

- Modules have memory. The device allows you to record current indicators and compare all measurements over a long time.

- Accuracy of adjustment - measuring modules literally “adjust” to the indicators of the supplied gas.

- Electronics needs more protection. But as a result, the entire device is more durable.

Models may include options: a shut-off valve that triggers when a gas leak occurs, a smart card reader mechanism that allows you to immediately pay for blue fuel.

Selection rules

The device is selected according to the recommendations of the gas company serving the building. On their part, these requirements are due to the features of the gas circuit, the degree of gas purification, and maintainability.

The user takes into account other characteristics:

- Throughput - the maximum amount of gas that the device can pass through is indicated in the product passport. The flow rate of the flow meter must exceed the total consumption of all gas appliances in the home by 10%.

- Design features - produce right- and left-side counters. Depending on the direction of supply of the gas mixture - left or right, select the desired type of device. The diameter of the connecting pipe is also taken into account: it must coincide with the cross section of the pipe.

- Thermal corrector - gas changes in volume when the temperature rises or falls. A conventional flowmeter is designed to measure at a normal temperature of +20 C. Thermocorrecor takes into account changes in volume.

- Date of manufacture - the life of the device does not begin from the moment of installation, but from the date of issue. It is indicated in the data sheet.

- Installation site of the meter.

- Intertesting interval - the larger it is, the less often you will have to pay for inspection.

The temperature in the apartment is stable. A temperature corrector is required in private homes and boiler rooms.

Mounting Features

Only employees of the gas company carry out the installation. However, the consumer should also know the basic requirements for installation:

Only employees of the gas company carry out the installation. However, the consumer should also know the basic requirements for installation:

- According to the rules, the temperature of the supplied gas should be in the range from -20 to +60 C. In fact, the smaller the spread, the better. If we are talking about a country house, threaded gas pipes should be insulated.

- Install the flow meter at a height of not less than 1.6 m. A distance from 0.8 to 1 m is maintained before the heating appliances that affect the meter’s operation.

- The room in which the meter is mounted should be well ventilated.

- In an apartment building before installation, turn off the gas supply in the entire entrance. On the supply pipelines, shut-off valves are closed.

After installation, the meter must be sealed before commissioning.

Advantages and disadvantages

The advantage of any measuring and measuring means is the ability to accurately evaluate the flow rate. An approximate measurement based on average consumption indicators actually makes the consumer pay 30% more. The counter solves this problem.

The disadvantages are related to the need to install, maintain and replace devices after the expiration of their useful life.These procedures are not free: the consumer pays for the meter, inspection and repair.