The most common gas supply method is to supply natural gas through a centralized gas pipeline. Autonomous gasification involves the storage of a certain reserve of natural gas in the tank. At the same time, the user does not depend on the mode and quality of gas communications, however, he is forced to periodically replenish his fuel reserves.

What is autonomous gasification

There are 2 storage options: cylinders and gas holders. The first method is suitable only for cooking in the country. An extensive tank provides fuel for a stove and oven, a heating boiler, heaters, a heating boiler.

Contained in the gas tank is not natural gas. It is very difficult to store methane: gas is liquefied at a temperature of -160 C under a pressure of at least 200 bar. It is extremely difficult and expensive to provide such conditions in a tank intended for domestic needs. Therefore, instead of methane, a propane-butane mixture is pumped into the gas tank.

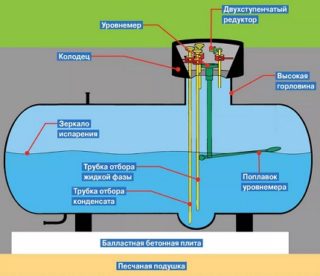

The gas mixture is stored in a gas tank in a liquefied form. The mixture is supplied to the outer pipes in a gaseous state, since it easily evaporates when the pressure in the gearbox decreases. Through the internal pipes, gas is supplied to the stove, boiler, boiler. Fuel can be used to generate electricity, if you put a gas generator.

The autonomous gas supply of a private house has many advantages:

- safety - leakage or fire is practically excluded;

- low price of the mixture;

- ease of use.

There is one important feature. In the cold, condensation forms inside the tank, which greatly interferes with the fuel supply. To avoid this, gas holders in Russia are placed underground. The depth of the trench under the tank depends on weather conditions. The gas holder should be located at a depth where the temperature never drops below 0 C. This makes installation of the device very difficult, especially in the northern latitudes.

Propane-butane gas burns with the release of 28.4 kW / m3. while the combustion of the same amount of methane produces only 9.4 kW.

Elements of an autonomous gasification system

The gasification system of any country house should include the following elements:

- The gas holder is a sealed tank made of high strength steel. Here the propane-butane mixture is stored under pressure. The deeper it is necessary to install the gas holder, the more robust the structure must be.

- Reinforced concrete slab - the capacity must be completely stable. The base eliminates the displacement of the tank during any movement of the soil.

- Cathode-anode protection - steel is prone to corrosion. In contact with the ground, this quality is enhanced, since the metal accumulates electricity, thereby provoking an electrochemical oxidation reaction. The protective system slows down rusting.

- Butane vaporizer - during prolonged cold weather, butane accumulates at the bottom of the system and shuts off the fuel supply.

- Gas pipelines - external and internal. The underground part can be made of polyethylene. Lay it at a depth below the level of freezing under a slope. However, under the rules, underground gas entry into the building is prohibited. To do this, equip the base input - a structure that includes a steel pipe, a crane and a bellows compensator.The latter provides gas to the house during any movement of the soil.

- Shut-off and control valves are valves, relief valves, safety valves, pressure regulators.

- Measuring equipment - sensors and devices for measuring pressure, temperature, accumulation level.

- Gas equipment - stove, boiler, boiler.

Some models are equipped with a manhole, through which a specialist can get inside the tank and inspect it. An additional valve can be installed in the basement module to shut off the gas supply to the house when a leak is detected.

Different types of gas holders

There are several types of gas holders. For autonomous gasification of any private home, category 1 reservoirs are used that are designed to store the gas mixture under a pressure of 3–6 bar. Category 2 models work at 30 atm. and are used in enterprises.

Gas tanks are classified according to a number of signs.

Depending on location

According to the installation method, ground and underground storage facilities are distinguished.

Ground models are placed above the ground on a concrete base. Earthwork is minimal, so installation is inexpensive. Inspection of the tank also does not cause difficulties. However, this solution is suitable only for regions with a warm climate, since even at 0 ° C moisture condensation occurs, which blocks the gas supply. In other areas, the structure must be insulated, which is much more expensive.

Another significant difficulty is the size. It is very difficult to establish such a large object in a small suburban area. You will have to sacrifice part of the garden and the yard, and this is not enough for anyone.

Underground installation is more complicated and expensive: you need to dig a trench, the deeper the colder the winter in the region, fill the stove, place a gas holder and pipes. But in all other respects this option is more profitable. The area of the site remains free, thermal insulation is not needed, gas does not escape into the air during leakage, but enters the soil, which eliminates explosion or fire.

By design

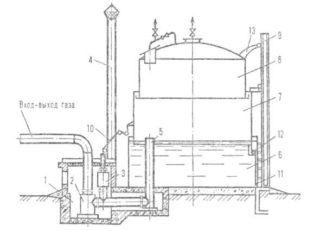

Distinguish gas holders with variable and constant volume. The first are used in an industrial environment. Here, the gas pressure is maintained by a mechanism separating the working and vacant volume of the tank. Gasification of the house is carried out by installing gas tanks with a constant volume.

Constant volume designs are divided into 2 types:

- Horizontal - gas tank capacity depends on the surface of the liquefied phase. The larger it is, the greater the volume of the vapor phase. In horizontal containers, the liquefied phase mirror is larger, therefore such models are more productive.

- Vertical - the surface of the mirror is smaller, which means that gas evaporates more slowly. However, the vertical design takes up less space.

If they live permanently in a gasified private house, horizontal containers are installed.

Neck height

For the gas holder to work efficiently, the fittings should be placed almost at ground level. This also solves another problem: the danger of flooding in high groundwater.

Low-neck models are installed in the southern region, where there is no need to lower the tank below the level of freezing. In the middle and northern latitudes, the gas holder is mounted at a depth of 1.5 m or deeper. In such cases, you need a tank with a high neck.

Lengthening the reinforcement casing does not solve the problem. Sealing creates a danger of explosion, since in this case propane-butane does not absorb into the soil when it leaks, but goes into the air.

Installation and Maintenance

The autonomous gas scheme at the summer cottage is the result of several specialists. Inside the building, the placement of gas appliances and a gas pipeline is designed by the architect. The external pipeline and the location of the gas tank are planned by a representative of the gas company.It is necessary to evaluate the relief of the site, analyze the building plan and only then find a place for the gas tank.

The project of a gas station for a private house needs to be approved. Only after this start construction.

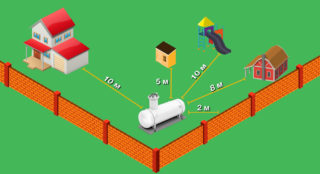

- The gas holder must be at a distance of at least 1 m from the residential building, at least 5 m from the garage, at least 10 m from the well or pool, at least 2 m from the fence. A pit is excavated at a selected site with a depth of at least 1.5 m. The customer can do this himself.

- At the bottom of the pit, a reinforced concrete slab is laid on a pillow of crushed stone and sand.

- A gas holder is installed on the base. Then equip the grounding, mount the pressure regulators, evaporator and other equipment. At the same stage, a condensate collector is installed.

- They dig a trench and lay pipes to the basement entrance.

- The system is checked for leaks. To do this, pump air for a day. If there is no leak, the trench is covered with sand, and then with earth.

- Equip the basement and mount the internal gas pipeline.

- At the last stage, gas appliances are connected, gas detectors and measuring instruments are installed.

- Commissioning is carried out before the installation and launch of the gas meter. After completion, the meter is sealed.

Despite the large amount of work, autonomous gas supply is equipped in 1-2 days. From the moment of the first inspection of the site to the start-up of the system, an average of up to 7 days is required.

Design and documentation

Any gas supply system must be registered with the gas management. Reliability and safety are the main requirements for gasification. The proof is the project documentation:

- site plan, where all the buildings and laid communications are marked;

- technical specifications and passports of all elements of the system: from the gas holder to the gas meter;

- gas pipeline scheme - external and internal;

- building plan showing the location of all gas appliances.

You will also need papers evidencing the rights of the applicant: a passport, a document confirming ownership of the site, and so on.

Based on the documents, a project for the construction of an individual gas storage is developed and calculations are made. The project must be approved by the Ministry of Emergencies and environmentalists.

Then the proposal is submitted for approval to the city gas industry.

The cost of the system and gas

The price of autonomous gasification consists of 2 components: the cost of equipment and design and installation work. It is determined by:

- gasified building area;

- length of communications;

- type and capacity of gas tank;

- the availability and nature of additional equipment;

- the complexity of the project;

- location of the object - on average, gasification of houses in the city is cheaper.

Autonomous gas is a mixture of propane-butane. Its price is higher than methane - 17-18 p. for 1 liter. The cost of the mixture depends on the content of butane. Winter gas is more expensive - it includes only 10-30% butane. In the summer, the share is 40-50%. Butane at a low temperature evaporates much worse.

Advantages and disadvantages of autonomous gasification

An autonomous system provides many advantages:

- The work of gas appliances in the house does not depend on accidents on the highway or pressure changes. The gas tank delivers fuel under constant pressure.

- Gas for the home - the propane-butane mixture burns with the release of a large amount of heat .;

- The gas holder is safer. With a possible leak, the gas is absorbed into the ground, and does not escape into the air.

- Autonomous system is very easy to maintain.

- Gas equipment lasts longer. The propane-butane mixture does not contain sulfur compounds, and upon contact with them, the metal is destroyed faster.

Minuses:

- initial construction is more expensive than conducting a gas pipeline from the main;

- you should independently monitor the fuel level in order to replenish supplies on time;

- during the operation of the gas tank, condensation may precipitate, which disrupts the gas supply. This indicator needs to be observed.

Maintenance and inspection of the gas tank and pipeline should be carried out by gas service employees. The cost of repair and inspection is borne by the owner of the house.