GOST R 55473-2019 allows the use of polyethylene pipes for the installation of a gas pipeline. Apply purely polymer models and reinforced with steel or aluminum foil. Gas pipes made of polypropylene appeared later, therefore they are not regulated by GOST. However, these products are used for gas distribution in the house.

What a high-quality gas pipeline consists of

There are 4 types of gas pipelines:

- Main - gas pipeline of the 1st category. The gas pressure here is 0.6–1.2 MPa. Liquefied gas is transported under pressure from 1.6 MPa and above.

- High pressure gas pipeline - category 2. The pressure is lower - from 0.3 to 0.6 MPa.

- Medium pressure pipelines - from 0.005 to 0.3 MPa. These are systems discussed in urban areas.

- Low pressure - with indicators below 0.005 MPa. Blue fuel is supplied to the home without pressure.

The lower the pressure, the less durable the material can be. Characteristics are regulated by GOST R 55473-2019 and GOST R 55474-2013. For the supply of gas it is allowed to apply:

- Steel pipes - seamless from cold-rolled steel for a high pressure system, with a straight seam for high and medium pressure communications and gas-water pipes for gas distribution in residential buildings. Their advantages are strength, high tightness of pipes and joints, lack of linear expansion. At the same time, steel products are very heavy, they are joined only by a weld seam, they are prone to corrosion.

- Plastic - able to withstand pressure up to 1.6 MPA, however, it is forbidden to use them for laying liquefied gas pipelines. The plastic gas pipe is flexible with high strength: communication can have a very complex shape. The material is resistant to chemically aggressive substances and completely free from corrosion. However, a gas pipeline can only be underground. It is forbidden to operate in areas with a temperature below - 45 C.

- Copper - the metal is corrosion resistant, strong, ductile and very durable. However, it is suitable only for a low pressure gas pipeline.

The circuit is collected from pipes of different materials. Often the main line is made of steel, and in an apartment building gas is supplied to homes through plastic gas ducts.

Varieties of plastic pipes for gas and their characteristics

Plastic pipes mean the entire range of polymer products. Not all of them are suitable for gas transmission. The main difference of special plastic gas pipelines is a high degree of gas impermeability.

- Polyethylene - have sufficient strength, impervious to gas, resistant to chemically aggressive substances.

- Polypropylene - appeared on the market rather late, therefore they are not regulated by GOST standards. This limits their use. Officially, gorgaz may refuse to accept the system assembled by their polypropylene pipes. It is recommended to use reinforced.

- Polyvinyl chloride - used for the organization of sewers and gas pipelines of low pressure. Cheap, but faster fail.

- Polypropylene

- Polyethylene

- PVC

To transfer gas, special products with the corresponding marking are produced. It is forbidden to use pipes designed for water supply or drainage for a gas pipeline.

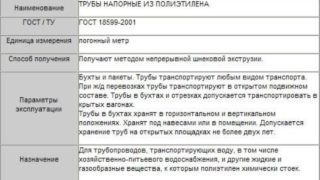

Low and high pressure polyethylene pipes

Low and high pressure polyethylene has different qualities. Products from it are exploited in various fields:

- LDPE - temperature sensitive.It cannot be operated already below 0º C. At temperatures above +40 C, the material softens and the pipe deforms. The gas and vapor permeability of the LDPE is quite low, but does not allow the transfer of gas. LDPE pipes are used for cold water supply and sewerage.

- HDPE - the material is much more rigid and durable due to additional stitching. The temperature range of operation is much wider, and gas permeability is 5 times lower than that of LDPE. Polyethylene pipes are used for the construction of a gas pipeline, starting from category 2.

Significant parameters of PND pipes for gas supply:

- Low gas permeability - methane and propane molecules are very small, so a material with high permeability does not provide sufficient tightness.

- The walls of the product remain smooth throughout the life of the product. This facilitates the transfer of raw materials especially over long distances.

- The service life of plastic pipes is at least 50 years. This is much higher than steel counterparts.

- Polyethylene does not corrode and does not need protection.

- The polymer is a dielectric. Unlike steel piping, plastic does not accumulate electricity and does not require specific maintenance.

Restrictions on the use are associated with insufficient mechanical strength of the material. The gas pipeline can be laid only underground, but at a depth of not more than 1 m. Under the autoway or other areas where the load is very high, the pipes are protected with special cases.

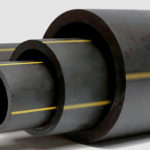

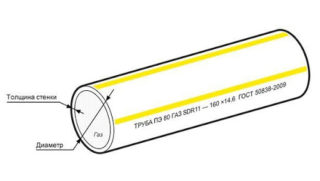

Polyethylene pipes for gas are marked accordingly. Color - bright yellow or with yellow stripes. For a gas system use:

Polyethylene pipes for gas are marked accordingly. Color - bright yellow or with yellow stripes. For a gas system use:

- PE-80 - withstand pressure of 3–6 atm, wall thickness of 2–3 mm. Models with an SDR of 17.6 and 11 are available. The latter tolerate higher pressure.

- PE-100 - designed to transfer gas under pressure of 8-12 atm. The wall thickness is 3.5 mm. They produce PE-100 with an SDR of 17.6, 11, and 9.

Diameters range from 32 to 630 mm.

Although HDPE pipes withstand pressure up to 16 atm, they are not suitable for a category 1 gas pipeline.

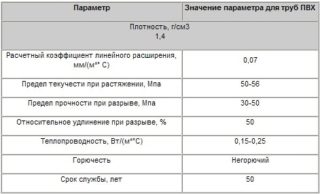

PVC pipes

PVC products have many advantages. They are lightweight, strong enough, poorly breathable. Nevertheless, their use is very limited by a small temperature range - not lower than 0 C and not higher than +45 C.

Since the material is chemically inert, PVC pipes are used in the oil industry. However, they are not suitable for supplying oil and gas.

In private homes you can find sleeves made of corrugated PVC pipe. Their length does not exceed 2 m. However, it is impossible to build a gas pipeline from this material: gorgaz will legally refuse to register such a system.

Polypropylene

Is it possible to use polypropylene rather than polyethylene pipes for gas, a moot point. Compared to polyethylene, its density is lower - 0.91 g / cm3, which is the lowest among plastics, the material begins to soften at +140 C. On the other hand, polypropylene is harder and less susceptible to wear, chemically inert, and is only very affected strong oxidizing agents, however sensitive to the sun and oxygen. The latter is the largest drawback of plastic used to produce pipelines. It is compensated by the addition of stabilizers. A more reliable option is reinforced polypropylene pipes, since aluminum or steel foil does not allow oxygen to pass through.

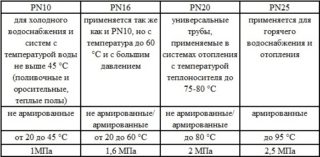

The following brands are produced:

- PN 10 - designed for cold water supply. Pipes withstand pressure up to 10 atm, but tolerate temperature only up to +45 C.

- PN 16 - withstands pressure up to 16 atm, the temperature of the working medium can reach +60 C. However, it is not used for the gas pipeline, since it has too high gas permeability.

- PN 20 - transfers pressure up to 20 atm. Used for installation of water supply circuits.

- PN 25 - the most resistant.Allowed parameters: pressure at 25 atm. and temperature up to +95 C.

Polypropylene for gas is not recommended because of the high gas permeability and sensitivity to light. The material has not been tested as the basis for a gas pipeline.

Features when comparing with steel counterparts

Steel acts as a reliable material for the gas pipeline due to zero gas permeability, the ability to create tight joints and high strength. However, the metal also has a drawback: high weight, the ability to accumulate electricity, a tendency to corrosion. A plastic gas pressure pipe can replace steel in some cases.

Advantages of polymer materials compared to metal:

- Polymer plastics are insensitive to corrosion, unlike black steel.

- Polyethylene does not accumulate electricity. A gas pipeline made of plastic does not require special protection, while a metal pipeline is equipped with at least a cathode and periodically take measures to "remove" the accumulated charge.

- Plastic is chemically and biologically inert: it does not decay, does not decompose, and does not react to the effects of acids, alkalis, fats, saline solutions.

- The walls of polypropylene or polyethylene pipes remain smooth throughout the entire life cycle. System performance changes over time.

- The material is quite flexible, a large number of various elements allow you to mount a contour of any complexity.

- Plastic lasts up to 50 years, and the duration of the operation of steel lines does not exceed 10-15 years.

- Plastic pipes are lightweight. Installation of the gas circuit takes a minimum of time and does not require sophisticated equipment.

Disadvantages of a plastic gas pipeline:

- The gas permeability of plastic is higher than that of metal. It is impossible to transfer gas under high pressure, although purely mechanical material can withstand such a pressure. Polyethylene pipes may be used in gas pipelines not higher than category 2.

- Lay the system only underground. In the house, pipes are placed on the wall.

- The outer pipes must be protected from the action of the sun.

- Plastic is flammable. The material is self-extinguishing, but this is not enough to ensure complete fire safety.

In apartments and in a private home, plastic pipes are preferred, as they are easier to maintain, more aesthetically pleasing and more durable.

Features of the installation of plastic pipes for gas

The recommendations are simple and related to the features of the material:

- PE pipes do not tolerate direct sunlight. The circuit is protected from the sun or laid underground. This requires preparation: marking, digging trenches, backfilling.

- The mechanical strength of plastic is inferior to steel, so the gas pipeline is installed in secluded places.

- In contrast to metal, the coefficient of thermal expansion of plastic is much higher. This does not affect the functionality of the pipeline, but obliges you to lay pipes in an open area. Installation under the floor or walls is undesirable.

- Plastic attracts with its flexibility and the ability to build a complex system. It should be noted that the fewer bends and turns in the system, the better it functions.

- Every 2-3 meters, the pipe, both vertical and horizontal, must be supported by an additional fastening or support.

For installation, crimp or extruded fittings are used. They guarantee reliable docking.

Mounting Methods

Connect the plastic pipes by welding. The method is very simple, since the welding temperature is low, even a novice master can handle the docking.

The most popular 3 methods:

- Joint - mount perform joint in joint. So lengthen the pipe or make a branch.

- Vrastrub - when connecting to the joint, an additional layer of polymer is welded.The method is recommended for pipes with a diameter of more than 15 mm.

- Electrofusion - gas ducts are connected by welding through a fitting. So they change the direction of the pipeline, make branching or merging.

All methods provide a tight connection. Electrofusion - the most convenient and fast.