The most important condition for the operation of the gas supply system is the complete tightness of the pipes and connecting elements. To verify that the system is ready for action, a control pressure test of the gas pipeline is performed. Without this last test it is forbidden to put into operation a pipeline of any level.

The need for control pressure testing of the gas pipeline

Crimping is a procedure carried out to test a closed system working under pressure for strength and density. The test is carried out by pumping air under pressure into the circuit, the value of which is higher than the working pressure in the network. At the same time, it is easy to detect the smallest errors when joining pipes or welding seams.

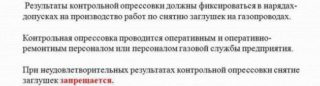

After the crimping, the selection committee draws up an acceptance certificate and allows you to start the gas pipeline. If malfunctions were found, the commission issues an order to eliminate the identified defects. The acceptance certificate is signed by the installation and maintenance company. Frequency not established: tests are performed as needed.

Preparatory work

Before the control pressure testing of the internal gas pipeline, certain preparatory work is performed:

- checking the scheme of the actual placement of the gas pipeline and its compliance with the data of technical documentation;

- selection of the installation location of all plugs, sensors, meters and compressor;

- employees undergo additional or repeated training on compliance with TB and inspection regulations.

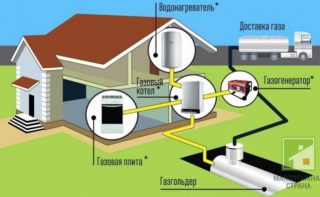

Gas and gas pressure testing is performed not only when the system is put into operation in an apartment building or at an enterprise. The test is also performed when connecting new equipment, after repair and replacement of part of the pipes.

Norms and rules for crimping

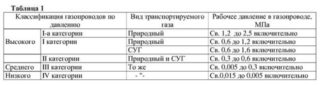

Testing of internal gas pipelines is regulated by GOST R 54983 2012. General rules are the same for testing any part of the circuit under high and low pressure.

- Pressure testing of gas equipment and pipelines with air is carried out before the line is cut into the central highway.

- For testing, air is injected into the cut-in section of the gas pipeline under a pressure of 100 kPa and held for at least 60 minutes. Measure the pressure in the circuit with a pressure gauge. The accuracy class of the device must be less than 0.6.

- If the circuit is tight, the gauge of overpressure is maintained until the end of the crimping. If the pressure gauge detects a decrease in pressure, there is a leak in the pipe. According to SP 62.13330.2011 re-crimping is done six months after the control.

For pressure testing use air or inert gas.

In an apartment building

Pressure testing of the internal house gas pipeline is carried out after an external inspection. After maintenance, the gas pipeline is checked for strength. Air is pumped into the circuit with a pressure of 1 kgm / sq. see. So check the pipeline from the switch at the entrance to the house or to the landing to the cranes on holidays to the devices. A complex gas pipeline is checked by dividing into separate sections.

If gas meters are mounted in the building, they are turned off during pressure testing, and the sections are connected by a jumper. Testing begins 3 hours after the pressure rise.Check for leaks with soap and water. If defects are detected, the commission fixes them.

Crimping gas inner tubes includes a density test.

- The gas pipeline is filled with air under a pressure of 400 mm of water. with working meters and gas devices. If there are no meters in the circuit, air is pumped under a pressure of 500 mm of water. Art. The gas supply system has passed the test if, within 5 minutes, the pressure drop does not exceed 20 mm of water. Art.

- When connecting new gas equipment to a gas pipeline already existing in an apartment building, pressure testing is carried out by gas. The emulsion is applied to all loose and threaded connections to check for leaks.

- Automation devices only check for density. Air pressure during pressure testing reaches 500 m of water. Art.

It is strictly forbidden to cover defects of any type with putties.

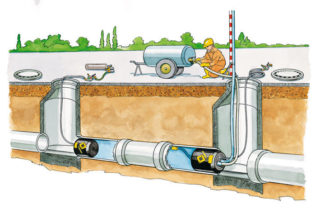

Underground gas pipeline

Pressure testing of the underground gas pipeline is carried out after installation in trenches and full or partial backfill - at least 20 cm. Each section of the line, from plug to plug, is checked separately.

- Tests begin with air injection under test pressure. Withstand the time required to equalize temperatures.

- Measurements are made with pressure gauges with accuracy class 0.4 or 0.6.

- A section of steel and polyethylene gas pipelines is crimped separately.

- Pressure testing of underground external gas pipelines laid in cases is carried out three times. For the first time immediately after welding and before laying. Then, after backfilling into the trench, and finally, along with the entire gas pipeline.

- Verification of multilayer pipes is carried out in 2 stages. First, they test for strength by pumping air for 10 minutes with a pressure of 0.1 MPa, and then test for leaks under a pressure of 0.015 MPa.

Testing of special technical devices is carried out according to the standards for lines with the same pressure.

Internal low pressure gas pipeline

Pressure testing of equipment and the internal gas pipeline is carried out with an air mixture under a pressure of 1000 mm of water. Art. The surveyed area is from the main crane to the switch in front of the burners. Testing lasts 1 hour. During this time, a pressure drop of 60 mm of water is allowed. Art.

Pressure testing in an apartment building includes inspection and verification of household equipment.

- A manovacuum meter and any device with a variable volume will be connected to the nozzle of the gas stove. With its help create excess pressure up to 5 kPa.

- Open the valve of the burner under test and fill the tank with gas.

- Close the tap on the gas pipe. Gas is squeezed out of the container to create pressure.

- The burner valve is closed and the tightness is checked with a vacuum gauge: after 5 minutes, the pressure can drop by no more than 0.3 kPa.

- If the pressure drops faster, there is a leak. It is found by applying a soap solution to joints and threaded joints. Once a leak is detected, turn the valve on the burner so that the gas pressure on it drops. Then one of the burners is lit, the gas is gently squeezed out of the tank and the pressure gauge and device are disconnected.

The selection results are entered into the acceptance certificate by the acceptance committee.

Crimping objects and algorithm of actions

The air test is carried out in the following cases:

- during the installation of internal and external gas pipelines, equipment, tanks, filling gas tanks;

- after the assembly of gas control points and installations;

- after replacing or repairing gas pipes or apparatuses, as well as connecting new ones.

Pneumatic testing of the gas pipeline for density and strength is strictly regulated.

- The studied section of the gas line is turned off. To do this, close the high pressure tap. Twist the low valve and install plugs at the ends of the circuit.

- If a break in the flange connections is detected, install jumpers.

- Connect the rubber-fabric sleeve and bleed the gas to a safe place. If possible, burn.

- The pipe is purged and mounted with a manometer and compressor. If the site is small, you can do with a hand pump.

- The compressor pumps air at the necessary pressure. After that, the tests begin.

When crimping, all shut-off devices on the air supply must be closed.

Gas pipeline pressure test results

Tests are considered satisfactory if the pressure on the site remains stable. The standards are as follows:

Tests are considered satisfactory if the pressure on the site remains stable. The standards are as follows:

- in an external gas pipeline, a change in pressure leaves no more than 10 daPa per hour;

- in domestic, the decrease does not exceed 60 daPa / h;

- in the internal gas pipeline of houses, a pressure drop of no more than 20 da Pa in 5 minutes is allowed;

- in liquefied gas tanks, the parameter can change by no more than 0.3 MPa in 1 hour.

If the pressure has changed above normal, the result of the pressure test is considered unsatisfactory. In this case, the site is inspected to detect leaks and repair the damage. The control crimping is repeated.

If the readings meet the standards, the site is taken into operation.

Basic safety provisions for starting gas into the system

When starting and checking the circuit, the following safety rules must be observed:

- The gas starts at a certain rate. The feed speed is maintained at the level of 15–25 m / s.

- When filling, the pressure should be kept at 0.1 MPa.

- All participants in the installation and inspection of the gas pipeline are required to wear protective suits, a helmet, and shoes. Workers should carry a fully equipped first-aid kit.

- The site on which the crimping is performed is fenced.

It is strictly forbidden to smoke, use lighters, carry out any hot work in the area of pressure testing the gas pipeline.