A practical and accurate gas pressure gauge is necessary for measuring fuel pressure in cylinders and other containers, as well as in gas pipelines. To choose the right device, you must first familiarize yourself with its structure, the principle of operation, classification, installation and operation rules.

Pressure gauges for measuring gas pressure

A gas pressure gauge helps to find out the differential, overpressure or full pressure values for general technical purposes. Such devices are divided into several categories according to the features of work, purpose and type of measured data. The standard view mechanism includes a case with a protective glass, a Bourdon tube, a link gear and a scale with an index arrow.

In the process of measuring indicators, the pressure inside the device acts on the tube from the inside and displaces its loose end. After the arrow comes into motion, stopping at the desired elevation. Good regulators for gaseous media have an increased level of resistance to vibration with a frequency that cannot exceed 10-55 Hz, amplitude with an offset of up to 0.15 mm, and accuracy classes ranging from 1 to 2.5.

Pressure gauge requirements

The exact indicators according to which the device takes measurements directly depends on the correctness of its selection and installation in combination with operating conditions. When selecting, the physical and chemical properties of the measuring medium and the expected pressure data should be taken into account. For example, for conditions with a high content of aggressive gases, it is better to purchase special devices made of durable materials. The diameter of the glass of the pressure gauge should be at least 10 or 16 cm, if it is placed at a distance of 2 to 3 meters.

Devices used in gas environments have different shades of the case, for example, blue indicates working with oxygen, yellow with ammonia, red and black are suitable for combustible and non-combustible gases, respectively. According to safety rules, it is not recommended to use pressure gauges with an expired verification period, as well as in the absence of a seal or mark on this procedure. If the arrow of the device does not return to zero after shutdown, it is also considered inoperative.

Any damage, such as deformation of the case or broken glass, indicates that the regulator needs to be changed, since they directly affect the accuracy of the meter.

Classification of pressure gauges by type of measured pressure

Classification of regulators according to pressure type:

- vacuum gauges and manovacuum gauges;

- barometers;

- head gauges;

- differential pressure gauges;

- gravimeters.

The principle of operation of any of them depends on the structure, in addition, it must be borne in mind that the meters are divided into categories within a single class, taking into account the level of accuracy.

Vacuum devices are designed for rarefied gas. Head gauges are able to determine the ultimate pressure parameters with indicators up to 40 kPa, traction meters up to -40 kPa. Other differential devices help you find the difference in performance at any two points.

Barometers are most often used to clarify only atmospheric pressure in a particular environment.

Functional classification

By the way they work, devices can be water, electric or digital, in addition to these categories, there are other varieties.

By the way they work, devices can be water, electric or digital, in addition to these categories, there are other varieties.

Water

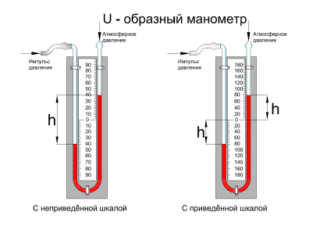

Water devices operate on the principle of balancing a gas substance with pressure, forming a column with a liquid. Thanks to them, one can clarify the level of sparseness, difference, redundant and atmospheric data. This group includes U-shaped regulators, the design of which resembles communicating vessels, and the pressure in them is determined taking into account the water level. Compensation, cup, float, bell and ring gas meters are also considered to be water, the working fluid inside them is similar to a sensitive element.

Electric

This household gas pressure transmitter converts it into electrical data. This category includes strain gauge and capacitive pressure gauges. The first ones change the readings of the conductor resistance after deformation and measure indicators up to 60-10 Pa with insignificant errors. They are used in systems with fast-moving processes. Capacitive gas meters affect the movable electrode in the form of a membrane, the deflection of which can be determined by the electrical circuit, they are suitable for systems with accelerated pressure drops.

Digital

Digital or electronic devices are highly accurate devices and are most often used for installation in air or hydraulic environments. Among the advantages of such regulators are convenience and compact size, the longest possible life and the ability to calibrate at any time. Basically, they are used to monitor the condition of the nodes of vehicles. In addition, digital type gas meters are included in the fuel lines.

Other

In addition to regulators with standard characteristics and settings, other types of instruments are used to obtain accurate data. This list includes deadweight gas meters, which are unique samples for checking similar devices. Their main working part is a measuring column, from which the error value changes from the state and accuracy of the readings. During operation, the cylinder is held inside the piston at the desired level; at the same time, calibration weights affect it on the one hand, and only pressure on the other.

Functional classification

By its purpose, the pressure gauge for high or low pressure gas can be general technical, reference or special.

General technical

Such devices help to measure the maximum and vacuum pressure and are most often used in production, including in the process of technological work. They are suitable for measurements in gaseous media, and they should be non-aggressive for copper alloys at temperatures up to 150 degrees. These devices withstand vibrational oscillations with limits from 10 to 55 Hz, an amplitude of up to 0.15 mm, and their accuracy class varies from 1 to 2.5.

Reference

Instruments of this type are designed to test, configure and calibrate other devices to ensure the most accurate measurements. Such pressure gauges for measuring gas pressure are divided into three categories, their list includes control and reference regulators, as well as their analogues, designed for ordinary and composite cylinders. Gas meters of the first type are used most often and help to control the reliability of these devices at the installation site, their operating limit ranges from 0.06 to 1600 bar.

Special

Special regulators create for a specific type of gas, as well as the medium formed by it. The housings of such devices are painted in a variety of colors, taking into account the type of substance for which they are intended.Manometers of this purpose are made of durable materials capable of withstanding the effects of gaseous media. They are considered the most common and have a simple design.

Instrument selection criteria

When selecting a device, all the requirements for pressure gauges used in the gas industry should be taken into account. The main criterion is the measuring range, during the selection process it must be remembered that the standard pressure must be in the range from 1/3 to 2/3 on the measuring scale. An ideal option would be a regulator with a scale of up to 0-10 atm. In second place in terms of importance is the indicator of the accuracy class, showing the normal error of the measurement results during the operation of the device.

If desired, this indicator can be calculated individually, for example, if the device is designed for 10 atm, and its class is 1.5, the error rate of such a gas meter is 1.5% of the total scale. According to the type of fitting fitting, the pressure gauges are radial or end-face; in addition, the regulators are supplemented with a metric or pipe type thread. When choosing a device, it is necessary to take into account its calibration interval, it will be better if it is two years.

Household devices may not go through the verification procedure, but it is mandatory for devices used in factories, gas pipelines, heating or furnace-type points, as well as similar objects.

Pressure gauge mounting

So that the gas meter can measure and regulate the pressure correctly, it is installed in areas where it will be as simple as possible to take indicators, carry out maintenance and repair of the device. There are limit intervals between the regulator and the walls that must be observed during installation. If the device is placed at a height of up to 2-3 meters, the diameter of its body must be at least 160 mm.

In addition to the mounting design of the pressure gauge, a three-way valve is installed, which is installed between the pipe and the regulator itself. If the unit is operated under conditions due to which high temperature, precipitation or other external factors can affect its functionality, it is additionally protected by siphons, buffer elements or other protection, as well as thermal insulation if necessary.