As a source of energy, not only ready-made natural gas is used. It is produced independently, by burning one or another type of organic fuel, in particular firewood. You can assemble a gas generator with your own hands, which will cost much cheaper than the finished unit. Combustible gases CO, CH4, H2 and others are formed in the gas generator, which are then used for various purposes.

The device and principle of operation of a gas generator on wood

Under ordinary conditions, with free access of oxygen, the process of burning wood is accompanied by the release of a certain amount of heat. But when oxygen is not enough for active burning, firewood smolders to produce wood gas, which includes combustible gases CO (carbon monoxide), H2 (hydrogen), CH4 (methane) and unsaturated hydrocarbons without resins. Also, non-combustible substances are formed at the outlet: CO2, O2, N2, H2O, which are ballast, and ultimately the gas mixture must be cleaned of them.

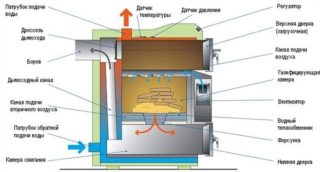

The gas generator is arranged as follows:

- The case is made of steel most often cylindrical in shape. There is a filling chamber into which fuel is loaded. The camera is mounted inside the housing and bolted. The loading chamber hatch is equipped with a seal.

- The combustion chamber is installed in the lower part, it is ceramic inside. The fuel burns in it. Resin cracking occurs in its lower part - there is a neck made of chrome steel with an asbestos cord, which plays the role of a sealing gasket between it and the body.

- Air is supplied to the combustion chamber through openings connected to the air distribution box, the so-called tuyeres. A check valve is installed at the outlet of the chamber to prevent the escape of combustible gas. A fan installed at the inlet allows you to increase engine power or burn fuel with a moisture content of more than 50% in a wood gas generator.

- The grate is located at the bottom of the gas generator and is designed to hold hot coals. It provides holes through which the ash falls into the ash pan. Its middle part is movable so that it can be cleaned.

- There are several loading hatches: the top with a shock absorber that lifts the lid at overpressure, and two side ones: one above to add fuel to the recovery zone, and the other below to remove ash.

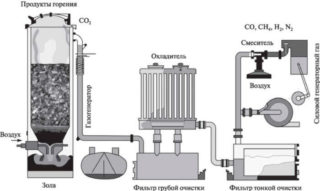

- A cyclone vortex filter is located behind the housing. Coarse gas cleaning is carried out here. Then the gas mixture is cooled in a cooler, enters the fine filter. After the filter, it is sent to the mixer, where it is saturated with air. Then the gas-air mixture flows to the place of use.

The pipeline through which gas is transported to the place of direct use is most often connected to a pipe installed in the recovery zone. While the gas is hot at the outlet of the gas generator, it can be used to heat water, to dry the firewood in the loading chamber. For example, in the latter case, a pipe is passed between the gas generator body and the filling hopper.

Combustible gas in the gas generator is obtained as follows:

- At the top of the loading chamber, the temperature is between 150-200 ° C. Due to the fact that an annular pipeline is organized through which hot gas passes, which has just left the gas generator, firewood is dried here.

- The middle part of the hopper is a dry distillation zone. At this level, the fuel is carbonized at a temperature of 300-500 ° C without access of air. Resin and acid are released from the fuel.

- In the combustion zone, which is located below the combustion chamber, the temperature is maintained at 1100–1300 ° C. Carbonized fuels, as well as tar and acids released from it, are burned up by the supply of air to produce CO and CO2 gases.

- The recovery zone is located above the combustion zone: between it and the grate. The CO2 gas that has formed in the combustion zone rises, overcomes the hot coal and interacts with the carbon of the coal, thereby recovering to form carbon monoxide. In addition to CO, CO2 and H2 are also formed.

At the exit from the reduction zone, the gas mixture is cooled, then it is cleaned of acetic and formic acid, ash particles and mixed with air.

Types of gas generators

There are gas generators of direct, reverse and horizontal process. In gas generators with a direct type of gas generation, air is supplied from below through the grate, and gas is taken from above. Such a gas generator is optimally suited for the combustion of semi-coke coal and anthracite. The power of the generator increases due to the enrichment of gas with hydrogen from water.

The reverse process gas generator is characterized in that air is supplied to the combustion zone, to the middle part, and gas is taken from the ash pan, below the combustion zone. In such a gas generator, gas is usually used to heat wood. The device is ideally suited for burning fuels containing resins: wood waste, firewood, charcoal.

In gas generators of the horizontal process, air is supplied from the side, at the bottom, and a fan is installed at the outlet of the air intake chamber to pump air. The active zone occupies a small place - between the lance hole and the gas vent. Such a generator quickly warms up and responds to changing operating modes.

The pyrolysis boiler has an improved design compared to a simple gas generator. It has two combustion chambers: in the first of them, fuel burns and combustible gas is formed, and in the other gas it burns and heat is transferred to the coolant. To turn the gas generator into a pyrolysis boiler, you need to add another combustion chamber and a heat exchanger.

The action scheme of the pyrolysis gas generator is as follows:

- Air is supplied to the combustion chamber through an adjustable window of the primary air intake chamber until firewood burns up.

- The oxygen supply is reduced. The boiler goes into gas generation mode, firewood begins to smolder slowly. This is achieved with the help of an automatic regulator, which reduces the access of air to the furnace.

- As a result, pyrolysis gas begins to be released. He enters the afterburner.

- When the boiler goes into gas generation mode, the secondary air necessary for afterburning is supplied. While the air reaches the desired chamber, it heats up to the temperature at which it reacts with the pyrolysis gas.

- In the upper chamber are air distributors with holes. Through them comes the secondary air, igniting the fuel gases. Due to this, pyrolysis gases are converted into thermal energy.

Emissions of hazardous oxides into the atmosphere are minimal, the temperature of the gases from the wood leaving the pyrolysis gas generator does not exceed 130-160 ° C. The heat carrier passes from the lower to the upper part of the boiler, taking thermal energy from all surfaces.

Connecting and starting a gas generator on wood

It is necessary to consider the features of using a gas generator on wood when connecting it to a car.Experts do not recommend completely abandoning gasoline, because it is problematic to start an engine on wood. It is recommended to start the engine by supplying gasoline, and only then switch to gas. Switching to different types of fuel can be organized using a mixer made according to the scheme of I. Mezin.

There are other limitations:

- The size of firewood is no more than 6 cm.

- Only dried wood is used as fuel, because additional heat is expended on the process of water evaporation, in this case less pyrolysis gases are formed.

- A wood-burning gas-generating engine loses 50% in power compared to a gasoline engine.

- Ignition is carried out with the fan on 20 minutes before departure.

Working on improvised fuel, the engine wears out faster.

Advantages and disadvantages of gas

One of the advantages of a gas generator is the wide possibilities of using combustible gas:

- for cooking food;

- for heating the house;

- as fuel for internal combustion engines.

In the first case, the pipes from the gas generator are led to the stove. In the second, the resulting gas is burned in a pyrolysis boiler and is used for heating residential buildings, greenhouses, as well as industrial premises, workshops and enterprises. Gas-fired internal combustion engines drive electric generators, pumping stations, and even automobiles.

In addition, other positive aspects stand out:

- Some models of gas generators on wood are autonomous. They can be installed where it is impossible to conduct electricity or where gas supply in cylinders is difficult.

- Compared with a solid fuel boiler, the efficiency of which is about 60%, the gas-generating boiler works with an efficiency of 80–95%.

- In an ordinary boiler, firewood burns out in 3-5 hours. In the gas generator, one tab burns out in about 8-12 hours, and the burning rate depends on the type of fuel and the device of the boiler. If the boiler is with top burning, firewood burns up to 25 hours, and coal 5-8 days.

- Wood fuel burns out completely, so you do not often have to clean the flue and ash pan.

- The power of the gas generator is adjustable from 30 to 100%.

- The gas generator practically does not emit harmful substances into the atmosphere.

- Installations are economical compared to conventional gas or liquid fuel boilers.

- Some gas generators cope with incompletely dried wood and even freshly chopped wood.

- It is not necessary to chop logs; you can lay firewood up to 1 meter long in gasgen.

- It is possible to load polymeric materials into rubber gas generator on sawdust and firewood: rubber, polyethylene, plastic.

- A gas generator is safer when compared with a solid fuel boiler.

Disadvantages:

- A gas generator costs about 2 times more than a conventional solid fuel boiler.

- Not all models can work without electricity, some devices use a fan to blow air, which requires an electrical connection.

- The consequence of using at incomplete power is unstable combustion, which leads to the formation of tar.

- A low return temperature (below 60 ° C) causes condensation to form.

- Some models work only on well-dried wood.

Given the cost of consumables, even a self-made wood-burning gas generator will be quite expensive.

DIY gas generator manufacturing

You can make a diagram of the gas generator yourself, having studied the principle of its operation, or use as a basis a drawing of a finished boiler and assemble its analogue. Craftsmen themselves even collect gas generators designed to generate electricity on wood.

To make a gas generator on wood for a motorcycle with your own hands, you will need:

- 100 liter metal barrel;

- thick-walled pipe with a diameter of 160 mm;

- filters for fine and coarse cleaning;

- stainless steel teapot;

- mower drive;

- hexagon;

- low temperature battery;

- chimney pipe;

- fire extinguisher;

- metal can;

- receiver.

Holes are drilled in the pipe for installing tuyeres. A hole is made in the disk from the rotary mower for the diameter of the pipe. The disk and pipe are welded together. A can is welded on top, as well as nozzles for supplying air and venting gas.

A fire extinguisher is needed to make a centrifugal cleaner. Two nozzles are welded to it - from above and from the side, and the fire extinguisher itself - to the barrel, which has no lid and bottom. In the barrel, in the lower part, a hole for collecting ash is cut out and closed with a threaded plug.

The welded construction of the pipe and can is installed in the barrel. Previously, the supports are welded to the disk and on the chains, from below, an ashpit made of a teapot is suspended. A barrel cover with a hole pre-cut in it is mounted on the can.

A cooler is constructed from a low-temperature battery and connected to the finished structure using flanges. Be sure to make a hole to drain the condensate.

The filter is made of two metal buckets of paint. They are put on top of each other and welded. Holes are made in the bottom. The top is filled with mineral wool, and the bottom with expanded clay.

The ignition fan can be made from the tractor's oven. It is installed in the front area of a motorcycle stroller with a subframe and connected to the system using polymer pipes. Two ball valves are mounted as gas supply regulators: one to the ignition fan, the other to the mixer. The mixer is placed in front of the carburetor and connected to the distributor. Under the carburetor, a collector of steel pipes is constructed.

The solid fuel hopper is fixed inside the housing or a part of the gas generator housing is diverted for this purpose by separating it with metal sheets.

To the bottom of the barrel is to weld the legs, which will ensure the stability of the structure.

It is necessary to carefully seal the self-assembled gasgen, because the lack of uncontrolled access of oxygen is the main condition for the correct operation of the device.

Operation tips

Gas generators, as well as heating boilers operating on the principle of a gas generator, are installed inside residential buildings, in specially designated premises - basements and basement floors. In addition, they can be placed on the street. The place is selected depending on the type of boiler and the features of its device. Pyrolysis boilers are often installed inside the house, because when they are serviced, a lot of garbage is not formed. In addition, the fuel is quite light and there are no special problems with its movement.

Gas generators working on wood, coal and especially designed for burning long logs are best installed outside the house: it will be easier to clean the device from ash and load firewood. In addition, the gasgen installed on the street is more fireproof.

If the boiler is located outside the house, it is necessary to perform bulk insulation so that the ambient temperature does not affect the operation of the gas generator in any way. It is recommended to protect the control system with a cover with a cover so that precipitation does not get inside. If the gas generator is used as a heating boiler, gas exhaust pipes are laid in the ground to avoid significantly cooling the gas mixture.

It is recommended to connect the chimney in the reverse order to the direction of smoke movement, then less particles of fumes and tar will accumulate on it.

The space around the boiler must remain free because it is very hot.