Natural gas methane and butane extracted in the deposits of our country after purification from impurities are odorless and colorless. This is their significant drawback: if a leak occurs or the flame on the stove goes out, it will be impossible to detect the presence of gas in the air, even in a strong concentration. This poses a great danger in terms of explosion and poisoning, because this type of fuel is toxic. In order to identify a dangerous situation in a timely manner, an odor gas additive is used.

Smelling Additive Requirements

Fuel has a specific smell due to additives that are introduced into it at gas distribution stations (GDS) immediately before being supplied to consumers. The odor of gas after odorization resembles hydrogen sulfide or rotten eggs.

The substances that are added to the gas have the following requirements:

- Physiological safety. People and pets should not be affected by contact with them.

- The absence of aggressive effects on the gas pipeline, including the devices and mechanisms included in its composition.

- Giving the gas a sufficiently pronounced odor so that it is detected even in a small concentration.

Empirically, such substances were created and began to be added to main pipelines, to cylinders for stoves and automobiles.

Features of odorants

The substance added to the odor gas is a product of mixing organic compounds released from methane and oil. Since both components are the result of rotting organic matter, their smell is appropriate. Even a small concentration of odorants in the fuel leads to the fact that the smell of household gas is sharp, sharp and extremely unpleasant.

The substance added to the odor gas is a product of mixing organic compounds released from methane and oil. Since both components are the result of rotting organic matter, their smell is appropriate. Even a small concentration of odorants in the fuel leads to the fact that the smell of household gas is sharp, sharp and extremely unpleasant.

One of the features of additives is that they completely burn out without emitting smoke and soot. Such non-waste and safe technology has been adopted by power engineers all over the world.

A leak can be detected even at the initial stage, when its size has not reached a critical level, which is 5% of the volume of the apartment. The smell of gas saturated with odorants is so noticeable that a person can already feel it when the concentration in the apartment is 1%.

Compositions and odor of odorants

The production of odorants, which are added to the gas for odor, is a separate area of the chemical industry. Today, the manufacturing of additives is carried out by two large enterprises. The reason for the release of a large amount of additives is that 68% of residential buildings and thousands of industrial facilities are gasified in the Russian Federation.

The production of odorants, which are added to the gas for odor, is a separate area of the chemical industry. Today, the manufacturing of additives is carried out by two large enterprises. The reason for the release of a large amount of additives is that 68% of residential buildings and thousands of industrial facilities are gasified in the Russian Federation.

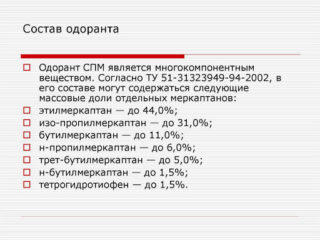

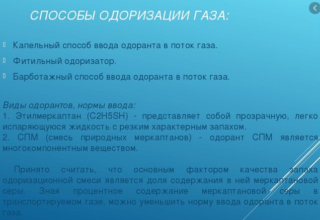

The most common and effective odorants are mixtures made from gas and oil condensate. They received the generalized name mercaptans. The compounds are based on technical alcohols, which provide volatility and combustibility of additives.

Another method of manufacturing additives is alkaline extraction of primary raw materials. Sulfide odorants are cheaper, but less effective. Upon contact with the metal pipes, substances lose some of their properties.

The high price of domestic gas is also explained by the fact that aromatic additives are introduced into it. But these are mandatory requirements of the current legislation, the purpose of which is to ensure the safety of citizens and the safety of their property.

Restrictions when added to gas

In a concentrated state, odorants are toxic and pose a danger to people.Based on this, for their transportation and storage, sealed containers with several degrees of protection are used. Tanks and warehouses are equipped with an alarm system, security is set at the entrance.

The concentration of fillers in the gas is regulated by GOST 5542-2014. In accordance with the requirements of the document, it should not exceed 0.0036 grams per cubic meter. In this case, a deviation in both directions of up to 10% is allowed. The rules for the preparation and use of odorants are described in more detail in the internal document of Gazprom WFD 39-1.10-069-2002.

Odorization Methods

Saturation of fuel with odor additives is carried out at the last stage of its transportation to the consumer at enrichment or gas distribution substations.

Saturation of fuel with odor additives is carried out at the last stage of its transportation to the consumer at enrichment or gas distribution substations.

Odorants can be added in the following ways:

- Steam saturation. Since mixtures of mercaptans are combustible, they are not heated, but sprayed through nozzles. As a result, the smallest aerosol is formed, uniformly distributed throughout the gas stream.

- Drip input. Additives are fed into the pipe in the form of a thin jet under pressure or falling drops. Then their rapid evaporation occurs under the influence of gas moving along the highway.

The odorization procedure is performed in manual or automatic mode. Calculation of concentration is carried out to determine the ratio of spent additives and pumped fuel.

The process of adding odor to gas

Before adding mixtures of mercaptans to the gas pipeline, their quality, concentration, composition and compliance with the requirements of GOST are checked. After this, the tank is connected to the installation and additives are pumped into its tank. Then the program is set if the equipment is automatic. In manual mode, the dispenser sets the parameters in accordance with the characteristics of the mixture and the pumped volume of gas.

Subsequently, the flow is switched between the units. Tucked starts to feed odorants to the highway. The devastated device stops, its maintenance, verification, refueling and preparation for further operation are carried out.

The operator does not need to check whether the gas has an odor, for this there are monitoring sensors that determine the concentration of mercaptans in it.

Safety measures when working with mercaptans

The odorants designed to prevent emergencies are themselves explosive and combustible substances of hazard class 2.

The odorants designed to prevent emergencies are themselves explosive and combustible substances of hazard class 2.

When handling them, the following safety measures must be observed:

- All manipulations with solutions and equipment in airtight rubberized clothing and gas mask.

- Double soil treatment with neutralizing solutions when mercaptans get on it.

- The presence of effective supply and exhaust ventilation in rooms where odorants are stored or used.

- Access restriction to the room where unauthorized persons reagents are stored. Reliable locks, locks, security and access control.

- Liquid transportation by special vehicles equipped with warning signs.

- The presence at the gas distribution station of sensors for determining gas leakage and odorants, as well as effective fire fighting means.

If liquid has spilled onto the floor, it should be fixed immediately with sand and then transferred to rubber bags for subsequent disposal.

If the substance gets on the skin and mucous membranes, they should be washed with warm water and soap and treated with a 2% soda solution. In the future, the injured need to be taken to a medical facility as soon as possible for diagnosis and medical assistance.