The electric plug is designed to connect electrical appliances to an energy source. The mains plug is always attached to the end of the cable coming from the motor or motor of the device. There are different types of devices that differ both in characteristics and in belonging to a particular type of electrical network.

Types of Plugs

Russian production of electrical appliances is somewhat different from European. However, the forks have similar features and appearance. Devices are collapsible and non-collapsible.

- C5 - is an analogue of the European device CEE 7/16. The pins are insulated to half their length. They have a rounded shape, their thickness is 4 mm. The maximum load current for a plug of this type is 6 A. It can withstand up to 1300 watts.

- C6 - similar to the European version of CEE 7/17. These devices, in turn, are two and three-pole (without grounding and with it). The diameter of the rounded pins is 4.8 mm. The maximum load current is 10 A, with this parameter the plug can withstand power up to 2200 watts.

- C1-b - equipped with round pins with a diameter of 4 mm. No ground contact. The maximum load current is 6 A.

The manufacturer indicates the amount of current that the plug is capable of conducting. This designation does not mean that the device can be used under the condition of a given current strength.

main parameters

During the contact of the plug with the socket, high voltage is transferred from the source to the consumer. This device has several parameters, without which it is impossible to select a product.

- The number of contacts. The most common plug option has two pins. The American plug with a wire is equipped with three contacts (grounding is present).

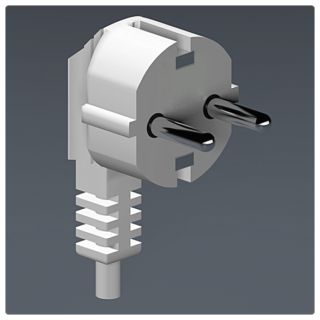

- The form. The fixture can be round, square, oval or angled. It all depends on what design the manufacturer of electrical appliances comes up with.

- According to the design variant, the forks are collapsible and cast. The first consists of a plastic case connected by special bolts. The non-separable device is made of dense rubber or rigid plastic.

- Conforms to a certain standard: European or American.

In addition to the parameters, it is necessary to take into account the convenience and safety of the plug when choosing.

Almost all modern forks are repairable provided they have a collapsible design.

Grounded plug

An electric plug with grounding is used if a three-phase network is installed in the house. Otherwise, the third contact will not be involved. This design is used exclusively in new buildings and creates additional safety when using an electric device.

Equipped grounding allows you to transfer a breakdown of current through a system of conductors, preventing the ignition of electricians and personal injury.

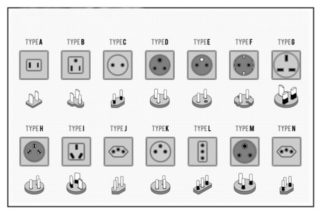

World markings

The marking on the wire plug depends on which country the structure was made in. For each state standard, it is customary to assign individual types of plug devices.

- American specimens belong to types A and B. Such devices have flat pins. Option A is manufactured without grounding, and the fixture with the designation B provides a place for its fastening.

- The euro plug is of type C. Equipped with two round contacts with missing ground.

- The designation D is assigned to devices of the English production. It has three contacts: one thin and two thick.

- The plug for a socket with flat contacts of type F is grounded, it has two plates for this.

- Two rounded pins are inserted into the French, and the third is arranged in sockets.

- Plugs for the Australian-type electrical cord are I, and in Israel they are assigned the letter N.

If electric plugs do not fit a standard household outlet, begin to sparkle, it is advisable to use special adapters or extension cords.

Features of Russian electric plugs

In Russia there are collapsible and molded forks. They are usually already installed on the cords of electrical appliances, therefore, do not require special inclusion. C5 type plugs are common, they have round thick pins. Suitable for powering equipment with power up to 1.3 kW.

There are single-phase plugs that come complete with powerful electrical appliances: saws, grinders, drills. Usually their design is non-separable, rubber is taken as the basis of production.

Designs of type C6 are found on different versions of household appliances. They are designed for power up to 2 kW, have two or three contacts with a diameter of 4.8 mm. Designs C1-b are intended for devices with a capacity of not more than 1.3 kW.

Which fork is better

Electrical plugs and sockets must match each other in the number of contacts and in the number of amperes. It is believed that the collapsible design of the plug is less reliable. In it, the contacts often loosen, connecting bolts relax after prolonged use. As a result, using the design is unsafe.

The molded products have a sturdy case with reliable rubber or rubber insulation. Such a plug can last much longer without replacement. Also, some features differ devices depending on the class belongs.

- Class A. Typically, structures of this type are operated in Central America and Japan. One plug is thicker than the other. This is done to maintain polarity.

- Class B. Designed for domestic use, has a grounding contact. Optimum current up to 15 amperes.

- Class C. European standard, has similarities with the options used in the USSR. Such plugs are convenient and are included in the connectors of a new type, while only a flat socket is suitable.

- Plugs of other standards. They are all different, but can have a single connection method. Therefore, each of the options can be operated on any of the continents. Samples with the designation D, E, F, and others can be used for electrical networks of the Russian Federation and Soviet outlets with a special adapter.

To create a unified standard of electrical connection on the whole planet, it will be necessary to shut down all energy systems for a while.

Fork Connection Rules C1-b

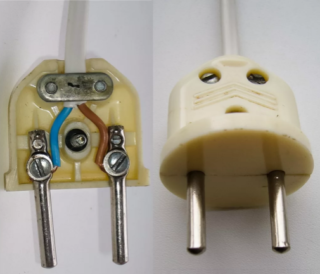

For each individual device, depending on its class, there are individual connection nuances. Collapsible plugs should be connected if the pins are in good contact with the conductors.

- The insulation is removed from two contacts at a distance of 2-2.5 m from the ends.

- Rings are formed and cleaned from veins.

- Contacts are switched with pins.

- Fit in seats.

- The details of the plug body are interconnected and twisted with bolts.

Be careful when stripping insulation, it is better to use special scissors.

Attaching the wire to the plug C5 and C6

In devices such as C5 and C6, special compartments for installing contacts are already provided. Power cables, consisting of three conductors, must be folded in half and twisted before connecting to the pads. Then the contacts are simply clamped in the seat with special screws.

If there is no ground contact in the outlet, the green conductor must not be used and connected to the base of the appliance or left open in the wall. It is better to insulate it for reliability.

When installing the plug on a powerful electrical appliance, it is necessary to provide for possible overheating. It is desirable that the plug-in device has a power reserve, in no case should the indicator be less.

When replacing the plug on the wire, it is important to take into account all the marking designations and the features of the outlets that will be used as the power source of the electrical appliance being repaired.