The number of technologically new household appliances and tools is growing. Accordingly, there is a need to purchase a cable for connecting to the network. It is important to know how to choose a durable, flexible and fireproof PVA wire.

PVA wire: decoding and application

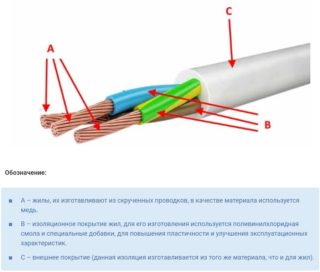

It is the best option for living conditions, which makes it especially popular. The abbreviation indicates its following characteristics: “P” - wire, “B” - vinyl insulation; "C" is a connecting one. The product is round in section.

There are options marked with PVSP. In this case, the veins are parallel, and their shape in the section is oval. It is often called flat. The PVS-T marking can be decoded as operation in conditions of high dampness. The PVSN wire indicates that the product is of the fifth class of flexibility. The absence of the letter “A” at first indicates that the cores are copper.

It can be used in the manufacture of tools and electrical appliances, as well as in all spheres of human activity:

- connection and repair of household appliances;

- arrangement of temporary wiring in residential and domestic premises;

- as a connecting, extension cable for different needs;

- power supply for small agricultural and garden equipment;

- in production, for equipment with high energy consumption.

It is a structural element of almost all household appliances and locksmith tools.

PVA is a cable or wire

PVA - one of the most common types that can be used for networks with voltages up to 380 volts, has from two to five cores. Each core consists of thin twisted wires enclosed in a separate insulation. For ease of installation, the insulation of the phase conductors can be brown, white, red or black. Zero is painted blue or blue. Grounding conductor insulation is yellow-green. The general shell also has a wide gamut of colors.

There are a lot of options, they differ in the following parameters:

- The outer one has three cores - phase, zero, grounding. It is convenient for supplying power from an external transformer to a distribution board in a room.

- The inner wire is arranged in the same way. It has no protection against climatic conditions and dampness. It can be used indoors.

- Copper - high strength, has low resistance and increased conductivity, is resistant to corrosion.

- The advantage of aluminum is the price. Alumina treatment increases service life.

Decipher the labeling of other varieties as follows:

- T - resistance to mold and fungi;

- B - armored cable;

- U - increases the temperature minimum;

- PS - self-extinguishing shell;

- G - without isolation;

- SP - power;

- T - telephone cable.

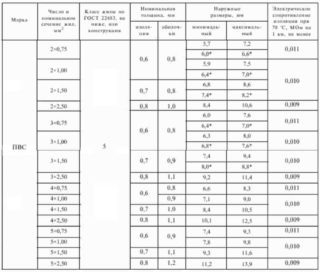

Also, the wire is divided into sizes according to the number of cores, weight and profile in the section.

Specifications

The main ones are the operational data, the number and cross section of the cores. For all types, the same characteristics apply:

- maximum allowable voltage of 450 volts;

- it is intended for networks where current with a frequency up to 50 Hz;

- permissible core heating up to 70 °, thermal stability - class Y;

- fire resistance class - standard;

- operating temperature from - 20 ° C to + 40 ° C.

The wire has increased mechanical strength, high resistance parameters. It is able to withstand up to 30 thousand bends.

What regulatory documents govern the use of

In the manufacture of PVA are guided by the requirements of GOST 7399-97. The section includes basic information about the assortment, a list of tests, safety requirements. The technical standard governs the basic mechanical and electrical threshold data. The manufacturer may change individual specific numbers within the specified acceptable limits.

In accordance with GOST, the wire according to the number of cores can have 4 versions. The cross-sectional area of the cores varies from 0.75 to 16 mm2. Products with maximum parameters are produced only by cable factories.

According to the norms, twisting of the wire 0.75–2.5 mm2 should be done in the left direction, without filler.

When working in a mobile position, the operating life is 6 years. In static mode, the service can last up to 10 years.

Mounting Features

When connected to a vending machine, plug and other device, the ends are exposed, stripped. According to the PUE, the wires are connected by crimping the tip.

When laying the network on the street, it is necessary to take into account temperature fluctuations, humidity, the negative impact of UV rays, the risk of mechanical damage. The main requirements are strength, hygroscopicity and resistance to burning. Outdoor laying is performed in corrugated pipes that are attached to a wall or other stationary objects.

PVA is not intended for laying in the ground. In extreme cases, it can be hidden inside a double-walled pipe. When mounting in a damp room, the connection rules must be followed. Twisting is not allowed. The best option is to use shrink tubing.

How to choose a PVA

Description of technical characteristics allows you to choose a product in accordance with the requirements and operating conditions. They release a cable 10 meters long in bays. The cost per meter depends on the number of cores and cross-section, the quality of manufacture and manufacturer.

Description of technical characteristics allows you to choose a product in accordance with the requirements and operating conditions. They release a cable 10 meters long in bays. The cost per meter depends on the number of cores and cross-section, the quality of manufacture and manufacturer.

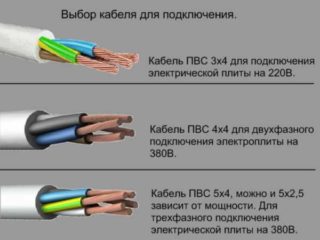

In everyday life, a three-wire wire is enough. It is selected depending on the power of the equipment to be connected. There are many fakes on the market, so it’s advisable to independently check the main parameters. In order not to purchase a counterfeit product, you need to check the certificate of conformity.

For industrial purposes, it is important to have a grounding conductor. For such electrical installations, a four-core copper cable is mainly used.

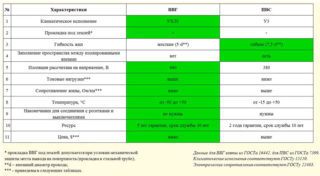

VVG cable in comparison with PVA

The VVG cable has good qualities and a relatively low price. Its purpose is AC networks: voltage from 660 to 3000 V, operating voltage from 1 kW to 3.5 kW. It can have from 2 to 6 conductors, core section 1.5 - 250 mm2.

They have the same copper conductive cores and PVC insulation. The main difference in flexibility class. PVA is elastic and belongs to Grade 5. The VVG cable has a 1 or 2 class. The diameter of the wire and their number in the core depends on this. For example, a VVG cable of class 1 flexibility with a cross section of 2.5 mm2 may have only one wire 1.78 mm in diameter. The same PVA will consist of 50 wires with a diameter of 0.25 mm.

The product has a different profile. The veins of small diameter are round, large - sector. Another difference is the thickness of the insulating material and the sheath. For the cable, the thickness of the inner layer is 0.8 mm, the outer one is 1.5. For PVA, respectively, 0.8 and 1.1 mm.

There are various modifications of the VVG cable. Concealed indoor wiring possible. It is used for outdoor installation. An air or underground power cable needs additional protection with a corrugated sleeve.

Advantages and disadvantages of PVA

The main advantage is the relatively light weight, softness and flexibility of the cord.This makes it possible to lay in complex systems, structures with a steep transition radius, a large number of bends and turns.

It can be used in electric networks at 220 and 380 volts. The wire has a standard fire resistance class. The insulation material does not ignite from an external flame and does not support combustion.

With it, it is not recommended to perform flush mounting, since the service life is not more than 6 years. Having a round cross section, it is inconvenient for installation under plaster.

PVA is widely used and is in great demand among customers. However, for electrical wiring it is better to choose the most suitable cable for this purpose VVG, VVGng, or another analog.