To automate the processes of turning on, reversing and disconnecting three-phase electric motors, an electromagnetic starter 220 V or 380 V is used. The device is compatible only with asynchronous motors, the supply voltage of which is no more than 600 V. Before connecting it, you must correctly select and study the circuit.

Areas of use

The purpose of the electric starter is to start, stop and reverse motors. The device is also suitable for controlling the lighting line, specialized equipment - pumps, air conditioners, conveyor belts, compressors.

Despite the fact that the contactor has supplanted the device, it is used in production or communication systems.

The principle of operation of the electromagnetic starter

For control, the start and stop buttons are used. The automatic device has a simple algorithm of action:

- Supply voltage to the active coil.

- Formation around an element of a magnetic field.

- Pulling in a metal core with fixed metal contacts.

- Short circuit of power contacts - current flows to the load.

The reverse is carried out using a coupling of two starters.

Device device

An electromagnetic starter for 380 or 220 V consists of the following elements:

An electromagnetic starter for 380 or 220 V consists of the following elements:

- core;

- electromagnetic coil;

- anchor;

- connecting frame;

- mechanical sensors;

- central and auxiliary contactor system.

Among the additional components of the device can be electric fuses, an additional set of terminals, a starter and a protection relay.

Starter design features

An induction motor, when turned on, has a starting current of 6 times the rated current. To prevent contact wear and loosening of moving parts, a magnetic starter is used.

An induction motor, when turned on, has a starting current of 6 times the rated current. To prevent contact wear and loosening of moving parts, a magnetic starter is used.

Sector designations

The principle of operation of the device can be understood from information from the sectors:

- the first indicates the scope and general data - AC frequency, current rating and conditional thermal current;

- from the second sector, you can find the maximum load power when connecting power contacts;

- in the third sector there is a graphical diagram with an electric magnet coil and contacts.

By the presence of a dashed line from the coil to the contacts, their synchronism of action can be determined.

Contact groups of the magnetic starter

The following markings are used to indicate power contacts:

- 1L1, 3L2, 5L3 - input elements designed to supply power from a direct or alternating current line;

- 2T1, 4T2, 6T3 - output contacts for connection to the load;

- 13NO-14NO - auxiliary elements for self-grip, help to keep the Start button steady while the engine is running.

The load or power source may be connected to any of the groups.

Stop key

Regardless of the modification, the control of the starter for the electric motor is performed using the “Stop” or “Start” button. Some models have a reverse mode. The stop button can be identified by the red color.

For unhindered current flow, normally closed contacts are mechanically connected to the stopper. Without pressing a key, the contacts are closed with a metal bar. To stop the device, you need to press the button - it will open. If there is no latch after lowering the button, the contacts will close.

For this reason, the electric motor is controlled using special circuits. To simplify installation, the device is mounted on a DIN rail.

Start key

The green or black button connects to normally open contacts mechanically. It differs from the stop key by the state of contacts. After pressing it, the circuit closes, and current flows through the contacts. The group of elements is held by a spring, which returns it to its original position.

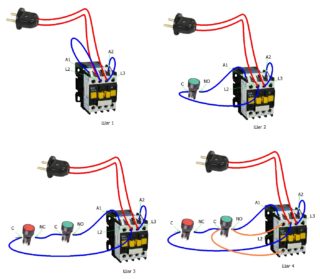

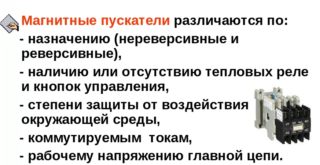

Device types

Starters for 380 V motors with squirrel-cage rotors allow you to remotely connect them to the network, reverse and stop. Devices are:

Starters for 380 V motors with squirrel-cage rotors allow you to remotely connect them to the network, reverse and stop. Devices are:

- Open type. Installed in panels, enclosed boxes and places protected from dust.

- Closed execution. They are placed indoors, control buttons are on the case.

- Dustproof. Suitable for indoor and outdoor installation, as they are protected from dust and moisture by a special visor.

- Relay. Magnetic starter with thermal relay protects the motor in conditions of short overloads on the line. The relay switch is combined with the device or connected to it.

- Three phase. A feature of a three-phase starter is the inadmissibility of an excess of the starting current above the nominal. If this is not the case, the phase is restored using the apparatus and uninterrupted operation of the motor is ensured at low starting currents.

With frequent overloads at the starter, the winding may burn out.

Design versatility

By design, magnetic starters come with 3 and 4 poles, i.e. with 3-4 contacts. The fourth in the normally open state blocks the control circuit.

By design, magnetic starters come with 3 and 4 poles, i.e. with 3-4 contacts. The fourth in the normally open state blocks the control circuit.

The electromagnetic mechanism is located inside and is a fixed W-shaped core and a coil with a winding. A movable unit is an anchor connected to a traverse and plastic. On it are contact bridges with active elements. For a smooth closure, springs are used.

A fixed group of contacts is soldered onto plates with screw clamps. With their help, you can connect the cable from the external line. Additional contacts are located on the side of the device.

Some models have a special cover for the main contact group.

Electric starters with thermal relays

Magnetic starters with thermal relays protect the motor from short overloads. The setting current indicators can be set using the regulator - it is turned with a screwdriver. To prevent short circuits, models with thermal relays are not used.

Degree of protection

The device with IP54 protection is suitable for installation in open areas, in a humid and dusty room. It is advisable to install modifications with IP20 protection inside the box. In addition to the numerical index, it is necessary to take into account the wear resistance of the device under conditions of frequent load drops.

The larger the numerical index, the less requirements for mounting the starter.

Subtleties of connecting a device to 220 V

To connect a single-phase magnetic starter and prevent its vibrations, a din rail is used. The device must not be placed next to rheostats or in the heated part of the box. The tinned end of the conductor connected to the device is bent in the form of a ring or letter P. A layer of lubricant is applied to the aluminum cables (technical petroleum jelly, Tsiatim). The device is turned on according to several schemes.

Classic

Suitable if the load sources are motors or heating elements. The scheme consists of several parts:

- Power. This includes contacts in three phases, an automatic switch (placed between the input and the power source).

- Load. A powerful consumer is required.

- Chain. It consists of a start and stop button, coil, additional contacts, pops up on phase and zero.

Starter contacts are closed, and the voltage is supplied to the load after pressing the "Start" button.By pressing the stop key, the contacts open and voltage is no longer supplied.

Power circuit specifics

The single-phase starter is powered through contacts A-1 and A-2. They are supplied with voltage of 220 V, if a coil is designed for it. The phase is fed to A-2, the power source to the elements at the bottom of the case. Voltage can be supplied from a wind generator, battery, diesel generator. To remove it, the terminals are used - T-1, T-2, T-3. The minus of the circuit is the need to use a plug to turn the machine on or off.

How to change the control circuit

The power system of the device during modernization is not affected. They work according to the following principle:

- the buttons of the button post (in one casing) have normally open terminals at startup and normally closed at installation;

- the buttons are set in front of the magnetic starter in a sequential position - Start and Stop;

- contacts are manipulated using a control pulse;

- the start button supplies voltage to the coil and generates a pulse;

- Key support is carried out using self-locking contacts that supply voltage to the coil;

- self-locking contacts open, self-feeding the coil.

The magnetic starter stops after breaking the last circuit.

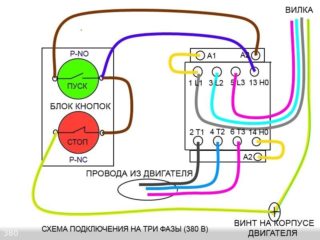

Connection to a three-phase network

The starter is connected to a three-phase network by means of a coil, which operates from a 220 V network. The signal circuit is not finalized. Phase and zero pop up on the corresponding contacts. The phase wire extends between the start and off buttons. The jumper is installed on normally closed and open elements.

The starter is connected to a three-phase network by means of a coil, which operates from a 220 V network. The signal circuit is not finalized. Phase and zero pop up on the corresponding contacts. The phase wire extends between the start and off buttons. The jumper is installed on normally closed and open elements.

The power circuit is slightly upgraded. The phases are fed to the inputs L1, L2, L3, the load is fed to T1, T2, T3.

This circuit is suitable for an induction motor.

Service Specifics

For proper maintenance, it is necessary to deal with device malfunctions. Elevated temperatures are the consequences of inter-turn short circuits of the coil, which must be changed. Overheating is also observed with poor connection of the contacts, their wear or overload of the network.

If the machine is humming, the anchor does not fit snugly to the core, is dirty or damaged. When seizing the active parts or lowering the voltage by 15%, it is necessary to check the tightness of the contact clamp.

Magnetic starters are used to protect asynchronous motors. Before connecting the device, you need to understand the scheme of its operation, the possibility of integration with a thermal relay and the specifics of changing the control mechanism.