The construction of a residential building includes the installation of electrical wiring, to which many devices of various capacities are connected. Despite their reliability, there is always a risk of breaking current through the housing and human injury. In addition, there is a high probability of lightning falling into the structure, which is fraught with fire and destruction. To make life in the house safe, you need to equip the grounding in accordance with the EMP, which will ensure the absorption of electricity by the ground in case of emergency.

Issues addressed in the EMP

The Electrical Installation Rules approved by the Ministry of Energy of the Russian Federation regulate the scope of application of protective equipment, grounding rules and the procedure for its arrangement.

This term refers to a combination of metal parts that, when assembled, provide electrical contact between the devices and the ground. The document describes the equipment grounding requirements, specifications, and standards.

- Means of production. These include machine tools, hoists of all types for people and goods, refrigeration units, generators, electric motors, heaters, conveyors and other products installed in the factory floors.

- Electrical appliances for domestic and industrial use. The neutral grounding of the transformer according to the PUE, stabilizers, KTP, rectifier and storage devices is regulated.

- Residential and private houses, cottages and cottages. In buildings of the old construction, only the grounding of cabinets according to the PUE is carried out. Connection of apartments with outlet to sockets is carried out individually at the initiative of residents.

- Pipelines through which explosive and combustible materials are transported - oil, gas, gasoline, diesel fuel, solvents.

- Power transmission towers. Grounding requires a structure made of metal, which is an excellent conductor of current. It is also necessary to equip concrete pillars with a protective structure, the height of which does not exceed 6 m.

- Metal towers for spotlights, antennas and for observers. In addition, the buildings are equipped with lightning rods.

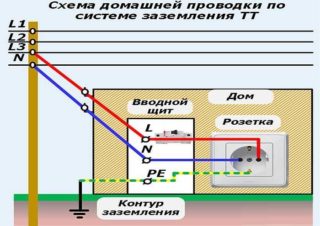

In accordance with the PUE, the ground loop should provide a guaranteed reception of electricity leakage under any conditions. For this, installation standards for various types of soil have been developed.

Circuit design

Regulates the apparent grounding of equipment clause PUE 1.7.139. In accordance with the document, the connection of parts should be distinguished by strength and reliability, structurally ensuring continuity of the chain. To distribute energy to consumers, an electrical cabinet is installed, which itself is re-equipped with appropriate protection against penetration into the case.

Regulates the apparent grounding of equipment clause PUE 1.7.139. In accordance with the document, the connection of parts should be distinguished by strength and reliability, structurally ensuring continuity of the chain. To distribute energy to consumers, an electrical cabinet is installed, which itself is re-equipped with appropriate protection against penetration into the case.

The components of the grounding system according to the EMP are as follows:

- Circuit board. The part is located in the switchboard, into which cables from grounded objects are routed. The line to external structures is fastened with a nut and bolt. The door of the shield must be permanently locked. As a rule, switchboards are installed inside buildings. In the private sector, it is allowed to install the box outside, provided it is equipped with a canopy.

- Communication. Designed to connect the mounting box with a structure buried in the ground. The material is a copper cable with armor and iron rods, welded together. The line runs under the floor of the room, the external walls, along the drainage drain pan.According to the PUE, grounding of electrical equipment should be carried out by a cable with a cross section of at least 5 mm.

- Vertical pins. Designed for electrical contact with the ground. Depending on its type, they are driven to a depth of 100-250 cm. The pins are made of black iron or stainless steel. The choice is determined by the financial capabilities of the builder.

- Circuit. Serves as a harness for recessed pins. In accordance with the PUE, the building's metal structures must be earthed using a circuit with a side of at least 200 cm. An individual can ground their property with a frame that can be 80-100 cm in size. According to the PUE, the grounding circuit is dug to a depth of 50-100 cm.

- Connecting bolt. Designed for metal communications and circuit communication. The outer end of the part should be above the soil at a height of 15-30 cm. For safety reasons and to avoid mechanical damage, the contact is covered by a casing.

Installation of the current leakage protection system is carried out at a distance, the value of which is determined by the specifics of the structure. For residential buildings, it is 50-100 cm. For utility structures, a contour of up to 10 m is allowed. In this case, the connection must be made with a copper cable.

Soil effect on resistance

The quality of current absorption by the soil depends on its composition, density and humidity. The better these indicators are, the greater the guarantee that electricity will not pass through the human body, but along the path of least resistance.

The quality of current absorption by the soil depends on its composition, density and humidity. The better these indicators are, the greater the guarantee that electricity will not pass through the human body, but along the path of least resistance.

At a voltage of 1000 V, the soil resistance in ohms is:

- asphalt - 200;

- pond water - 40;

- permafrost soil (loam) - 2000;

- wet clay - 20;

- semi-solid clay - 60;

- decomposed gneiss - 275;

- heterogeneous clay gravel - 300;

- Dresva - 5500;

- ash and ashes - 40;

- silt - 30;

- yellow earth - 250;

- sand is moderately wet - 60;

- sandy loam (sandy loam) - 150;

- garden land - 40;

- salt marsh - 20;

- forest loam - 100;

- peat - 25;

- black soil - 60;

- wet crushed stone - 3000;

- dry crushed stone - 5000;

Conductivity decreases when the soil is wetted. In order not to deal with this event all the time, you should install a circuit on the north side where the sun does not fall. In addition, you need to stretch the cable with a resistance of not more than 0.4 ohms.

Device and types of circuits

According to the definition of the PUE, the circuit is part of the grounding system designed to ensure contact with the ground. Metal has a much lower resistance than the human body. The product attracts electrons, taking them into an array, directing excess into the soil through the pins recessed in it.

A mandatory rule is to immerse the product below the freezing point of the soil. This is because the frozen earth has a lot of resistance, which exceeds the conductivity of the human body. Seasonal soil heaving leads to deformation of the figure, which is fraught with rupture of welding and bolt joints. In addition, the depth of digging depends on the level of groundwater. It is recommended to lower the frame 50 cm higher from their top point.

The shape of the product does not matter. The choice is made based on the availability of space and the features of the local area.

The most common types of configuration of metal frames:

- rectangle;

- square;

- triangle;

- line.

In some cases, a decision is made to install a frame around the perimeter of the structure. Such a project is in demand for equipping electrical installations of high power. The total area allocated for the construction can be up to 20 sq.m. The size is determined by the current strength and voltage, which theoretically can break through the device.

For a small private house, an internal triangular structure with an edge of 100-120 cm is sufficient. To protect against damage to an object with a power of 50 kW or more, a circuit with a total length of at least 20 m is required.

Manufacturers offer to purchase ready-made kits consisting of parts with a threaded connection and a copper coating. The cost of goods is quite high, but not sky-high. The products have excellent electrical performance, assemble without welding, are efficient and have a long service life.

Types of material

Most often, ferrous metal without any coating is used for the manufacture of metal communications. Stainless steel is less commonly used for furnishing, although its contact properties have been maintained for decades. Copper and brass have excellent characteristics, but these materials have a high price and are quickly destroyed due to electrolytic corrosion. Therefore, iron is the most popular metal in construction.

For the manufacture of immersion electrodes, fittings with a diameter of 16 mm are usually used. These products are characterized by sufficient strength, durability and conductivity.

To assemble the frame, you can use these types of rolled metal:

- tape 12-30 x 4 mm;

- corner 30-40 x 4 mm;

- round pipe with walls of 4-5 mm;

- tee or double tee from 4 mm thick;

- profile pipe 20 x 40 mm;

- monolithic pin from 10 mm.

There are no strict requirements for the form of profiles. The main condition is their integrity and quality connection.

Since the metal is prone to oxidation, the quality of the contacts is gradually deteriorating. In addition, there is a likelihood of violating the integrity of the longitudinal parts if they are long in alkaline or acidic soil. The condition of metal bonds should be checked at intervals that correspond to the chemical composition of the soil. The information obtained will help to carry out timely repairs, to reduce to zero the risk of damage to people and damage to household appliances.

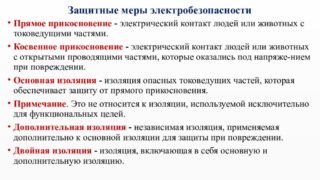

Electrical Safety Measures

Since metal communications can become a high voltage current conductor at any time, the entire system needs protection against unwanted contact.

Since metal communications can become a high voltage current conductor at any time, the entire system needs protection against unwanted contact.

The following electrical safety precautions should be observed:

- protect products from accidental contact;

- exhibit fences and fences;

- lay plates and open cables in a plastic box or corrugated tube;

- close the junction of the core and the circuit with a sealed box;

- install protective circuit breakers with a threshold of 30 mA in the circuit;

- provide automatic power outages;

- introduce potential equalization and equalization devices.

When carrying out installations of devices and fixtures, you need to ensure that they do not have a mutual influence, which may adversely affect the operation of the remaining options.

Do it yourself

Self-fabrication of grounding is a sequential process consisting of several stages, each of which has its own characteristics. For this, a pile of papers is not needed, since permission is not required in private construction. Installation should be carried out in the warm season, when the soil has thawed, dried out and the donkey.

Self-fabrication of grounding is a sequential process consisting of several stages, each of which has its own characteristics. For this, a pile of papers is not needed, since permission is not required in private construction. Installation should be carried out in the warm season, when the soil has thawed, dried out and the donkey.

To work, you will need:

- welding machine;

- grinder, puncher;

- level, tape measure;

- pliers;

- shovel, sledgehammer;

- brush, paint;

- corrugated tube;

- aluminum tape.

The work is performed in the following sequence:

- Designing a project. Based on it, the calculation of materials and equipment is carried out. A small margin should be made, as errors may occur during operation.

- Markup. The turf layer is carefully removed, then the foundation pit of a given shape comes off. The removed material must be stored, as it will go to the backfill.

- An even trench is dug from the middle of one side or from the corner to the building. It is needed for laying a cable or other current conductor between the frame and the electrical panel.

- Electrodes are cut out. Their ends are sharpened for easier immersion in the soil.After this, the pins are driven into the ground at the corners of the trench. If a corner is used, the holes are pre-drilled, and the openings are filled with a mixture of earth and salt.

- Saw the sides of the contour. They are connected to the electrodes and to each other. Welding spots are painted over.

- Near the ditch, a bolt is welded to the frame to the house. A cable is screwed to it. The joint is closed with a plastic bottle, the neck of which is sealed with aluminum tape.

- Entering the house is done in the basement. To prevent fraying of the cable insulation, a flexible steel tube is inserted into the hole. The cable is pulled into it and connected to the shield.

- The final stage is filling the ditches with soil, its leveling and tamping.

During operation, it is necessary to regularly water the location of the circuit with salt water. Especially often this should be done in arid times.