After replacing the wiring in the room, it is important to correctly and reliably install metering devices and all the necessary machines for the uninterrupted and correct operation of the connected equipment. After installation, all electrical devices must be checked for operability - load.

Briefly about circuit breakers

Circuit breakers or circuit breakers are electrical mechanisms whose main task in the event of emergency or emergency situations is to de-energize the problem line or the entire room. It monitors in real time the voltage in the electrical circuit.

Circuit breakers are widespread due to the affordable price, reliability and ease of use, installation and maintenance. A large number of modifications allows you to install the device in electrical installations of large and low power. Also, the switches are equipped with manual and remote control.

Loading Methods

During the loading, all the main characteristics of the device are changed - the protection response time in the event of an emergency, the rated current and the protection operation current. Check of circuit breakers should be carried out by qualified personnel, after which a mark with permission for further operation is left on the certificate.

The certificate must indicate the safety and voltage group at which employees can inspect electrical equipment. The paper is signed by the chief energy company.

Equipment for testing machines for breaking capacity

To check the difavtomat for operability, you first need to assemble a simple circuit, which includes the following equipment:

- current transformer - TT;

- connecting wires;

- an ammeter acting as a shunt;

- control key - KU;

- laboratory autotransformer for monitoring load changes - LATR or load transformer - NT.

Checking the difavtomat requires a partial dismantling of the device, and after checking the reverse installation.

How to check the circuit breaker for performance

For a full test of suitability requires the use of special equipment. Its loading is carried out to calculate the response time within the protected limits according to the factory characteristics. On the tested device, the load current parameter is set, which is equal to the maximum amperage for a particular model.

For a full test of suitability requires the use of special equipment. Its loading is carried out to calculate the response time within the protected limits according to the factory characteristics. On the tested device, the load current parameter is set, which is equal to the maximum amperage for a particular model.

When checking the thermal release on the circuit breaker, a triple load current and a maximum response time are set. As a rule, this time interval ranges from 5 seconds - 0.5 minutes.

The results of the tests must be recorded in a special protocol. In the normative document, the response times of the electrical device and the induced amperage should be displayed. A sample document is available on the Internet for free.

The need for operational verification

The regulatory documents do not clearly indicate the timing and frequency of inspections, so the frequency is completely dependent on the person who is responsible for the complete technical safety of the living space.

Electricians, relying on their experience, recommend that they be checked from time to time for electrical equipment.This is due to the fact that over time, each device wears out and may not work correctly or not at all fulfill the tasks assigned to it.

Setting a certain frequency, it is better to follow the recommendations of the device manufacturer. As a rule, European-made equipment does not need to be checked too often. If the circuit breaker was manufactured in China or at one of the domestic plants, it is better to carry out checks as often as possible. In any case, the owner has the right to choose.

When developing verification algorithms, a regulatory document is used - GOST 50345-2010: Household circuit breakers for protection against overcurrents.

Validation Results

The results of the verification must be recorded in a special protocol. Be sure to record information about the operation or, on the contrary, the failure of the device, the time and current at the time of operation.

The results of the verification must be recorded in a special protocol. Be sure to record information about the operation or, on the contrary, the failure of the device, the time and current at the time of operation.

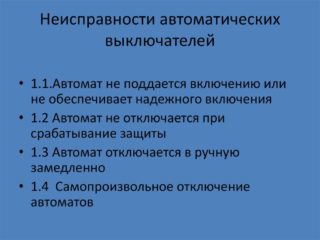

The device must be disposed of and replaced with a new circuit breaker in the following cases:

- the equipment is triggered, but after an acceptable period of time;

- when the trip current is not tripping;

- with a trip current, trip is detected.

Strict adherence to test regulations eliminates the possibility of further use of faulty equipment. Defective circuit breakers are calculated with high accuracy.

Test Dates

The frequency with which checks should be carried out is written in the accompanying regulatory documents, but the recommended frequency is once every three years, subject to all operating rules. With incorrect operation or regular emergency interventions, the frequency should change, an unscheduled check is carried out. This recommendation applies to all domestic circuit breakers.

Often, due to a short circuit, a breakdown of other working elements of the electrical circuit, for example, a ventilation system, is observed. This leads to great financial waste. In order to prevent such situations and save in the long run, it is recommended to regularly test circuit breakers and replace them with new ones if a problem is detected. To make sure that circuit breakers fulfill their protective function, it is required to set a certain frequency on the display with which suitability tests will be carried out.