A DC generator is an electrical equipment that produces a constant voltage. The device has a rather complex technical structure, which can be called the perfection of technical thought.

Operating principle

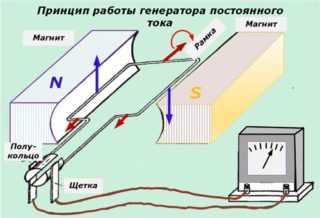

Each conductor is equipped with a magnet, to the ends of which a load is connected. When connected, alternating current flows continuously through them. The nature of its origin is explained by the fact that during operation, the poles of the magnet are continuously interchanged. The operation of an alternator is based on this principle.

So that the current does not change its direction, it is necessary to manage to connect the switching points of the load with a speed similar to the speed of rotation of the magnet. Only the controller can cope with the task - a small electrical device, which consists of several conductive sectors separated by dielectric plates. It is fixed on the anchor of the device and rotates with it synchronously.

Electric energy from the anchor is removed using brushes. Most often used are pieces of graphite with high electrical conductivity and low coefficient of friction.

Electric energy from the anchor is removed using brushes. Most often used are pieces of graphite with high electrical conductivity and low coefficient of friction.

All these processes contribute to the formation of a pulsating voltage of the same magnitude at the output of the electrical installation. To smooth out this ripple, several anchor windings are used. The more they are installed, the less will be the surge voltage at the output.

Characteristics and structure

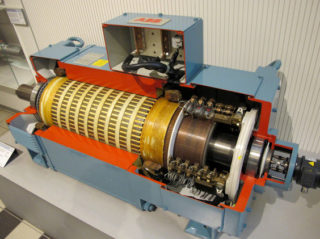

Like the vast majority of other electrical units, a DC generator includes a stator and an armature.

Like the vast majority of other electrical units, a DC generator includes a stator and an armature.

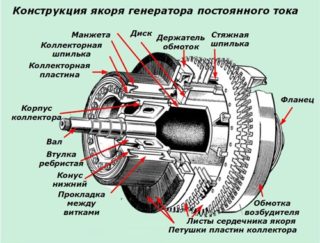

The anchor is made of steel plates with small recesses, windings are placed in them. Their ends necessarily commute with a collector, which is made of copper plates separated by dielectrics. At the end of the assembly, the shaft, the armature with the windings and the collector become one.

The stator performs not only its direct function, but also is a body, to the inner surface of which are attached electric magnets and permanent. The first option is preferable, their cores can be assembled from metal plates or cast along with the body. Also on the case there are special holes for attaching the collector brushes.

The number of graphites will vary depending on the number of magnet poles that the stator is equipped with. The number of brushes is equal to the number of pairs of poles.

Electromotive force

The electromotive force of a DC generator or EMF is a value that is directly proportional to the flux of magnets, the number of active conductors and the speed of rotation of the armature. With a decrease or increase in these indicators, it is possible to control the magnitude of the electromotive force and voltage. You can set the required parameters by adjusting the speed of the armature.

Equipment power and efficiency

The power of the DC generator is found to be both full and useful. With a constant electromotive force of the generator, the total power is proportional to the current strength.

The power of the DC generator is found to be both full and useful. With a constant electromotive force of the generator, the total power is proportional to the current strength.

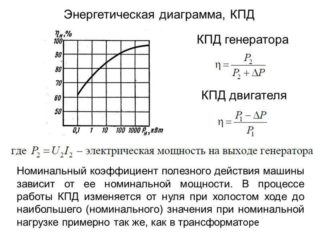

Another important technical characteristic of the alternator is its efficiency. This concept is the ratio of usable to full power.

At idle, the efficiency is zero, maximum performance is achieved at rated loads. In powerful innovative models of DC generators, the efficiency is close to 90%.

Varieties by way of excitation

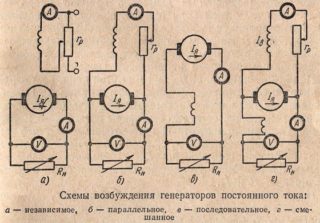

By the method of excitation, DC generators are divided into two types:

- with self-excitation;

- with independent excitation of windings.

Self-excitation of equipment necessarily requires electricity, which they themselves generate. According to the principle of switching windings, self-excited anchors of alternators are divided into the following varieties:

- parallel excitation equipment;

- series excitation devices;

- mixed-type generators, which are called - compound.

Each variety has its own design features, advantages and disadvantages.

Each variety has its own design features, advantages and disadvantages.

To ensure optimal conditions for the operation of the equipment, a stable voltage at the terminals is required. A feature of the device is the parallel excitation of the findings of the coil, which are connected through an adjustment rheostat located parallel to the armature winding.

For equipment with independent excitation, the power source is external devices or batteries. In low-power modifications, permanent magnets are installed, which ensure the creation of the main magnetic flux. The main advantage is that the voltage at the terminals is not affected by the exciting current.

Devices with mixed excitation combine the positive qualities of the above varieties. Design features - two inductors, main and auxiliary. The parallel winding circuit includes a rheostat, which is used to regulate the field current.

Application area

DC generators have a fairly extensive list of applications. It is actively used in almost all industries, especially in the automotive industry and in the construction of new-generation Russian locomotives, which are equipped with asynchronous motors, characterized by working on alternating current.

Also, electrical equipment can be used in everyday life for portable welding machines with an autonomous power supply system and for household appliances equipped with powerful starting engines.

Before buying, you should analyze what goals electrical equipment will need to cope with. Based on this, the most suitable modification of the DC generators is selected.

You can purchase equipment in specialized stores or on online sites. When buying, it is important to check the availability of all necessary supporting documentation and a warranty card. The integrity of the case and the presence of damage are also preliminarily examined: if any, it is better to refrain from buying. When buying online, you should carefully read the reviews about the store in various forums.