Press pliers for crimping wire ferrules is a mechanical hand tool whose main task is to provide a reliable connection between the sleeve or ferrule and the electric wire. Visually, it has many similarities with ordinary pliers, only instead of even lips it is equipped with embossed matrices. It is used in all industries, as well as domestic conditions.

Features and design differences

There are three types of press ticks, which differ from each other in the shape and size of the matrix, but they all have one purpose. A feature of such a tool is pin crimping, which is also called “point crimping”.

For ease of use, the equipment was additionally equipped with a ratchet mechanism, the peculiarity of which is that the handles will not be unclenched until the crimping cycle is completed.

Also, this device is equipped with a side wheel, which is very useful if you can not squeeze the sleeve to the end.

After the end of the crimping process, an imprint of the mark remains on the sleeve body. The design of the tool is simple, but it has functional and convenient handles that make it easy to work to the maximum. The handles are long enough, which allows less effort to crimp the wires.

Scope of press ticks

The crimp for the ends of the electric cable has a wide range of applications, since only it qualitatively and correctly connects electrical devices.

The most commonly used press for wires is radio technicians, car mechanics, and electricians. Not only ordinary cables, but also non-standard connectors with different terminals and connectors are operated for press contacts.

Crimp for wires is considered one of the most popular and useful tools for performing such tasks. Its cost is acceptable and affordable to everyone. However, the price is affected by the quality of the materials used and the manufacturer.

Thanks to the unique design of the tool, it is possible to make high-quality pressing of the tips without much effort - to create reliable contact between the main electrical equipment and all the conductors.

For stranded wires and thin-walled lugs

Such crimpers are used for crimping wires with a small cross-sectional area (from 0.5 mm), equipped with cable lugs - sleeve, pin. Crimping should be carried out to the maximum effort so that the person feels how the spring mechanism worked.

The need for crimping arises when multicore cables need to be connected to distribution boards, boxes and other electrical devices. If the work was carried out qualitatively, the likelihood of tearing of the cable veins is excluded.

For stranded wires and thick-walled lugs

For reliable crimping of thick-walled lugs, press pliers of other sizes are used. Each individual tool is characterized by the uniqueness of its working area. Each zone is indicated by marks located on the jaws of the instrument. The crimping range can vary between 1.5-16 mm. After crimping, the stigma remains on the back of the sleeve.

Before the procedure, all preparatory measures are performed. To begin with, strip the ends of the cable all the way to the end of the sleeve.The sleeve is selected so that it freely entered inside, but did not rotate. This point is important because the quality of the future crimp depends on it in many respects. All protruding veins bite off.

For cable of large cross section

If a power wire with a large cross-sectional area is used, it is not necessary to use standard pliers, but a large hydraulic press. This kind of tool appeared much earlier than the press tick. In everyday life, such equipment is not used, but it is in demand in various sectors of construction.

Matrices are selected depending on the dimensions of the sleeves and wires, therefore, as a rule, several types of cartridges with matrices of different shapes and sizes are included with the tool. The upper part of the device is magnetized, so it always returns to its original position without outside help. The lower element of the press changes.

Sequential wire crimping

This method has one significant advantage - crimping the sleeve completely eliminates the likelihood of air, moisture and other negative factors contributing to the active oxidation of the material.

Crimping computer cables

Crimpers designed to crimp a twisted pair belong to a separate group. The principle of their action is similar to the principle of operation of a press tick with two jaws. The design difference is that it uses a matrix of a special shape, and not metal bushings. This approach made it possible to mount an RJ45 type plug on a telephone or computer wire. Such a tool does not compress the contacts, but displaces them by cutting through the insulation in individual sections and tightly pressing it to the cores.

Types of crimping for wires

According to the principle of operation of the equipment is divided into the following types:

- dihedral;

- tetrahedral;

- Hex.

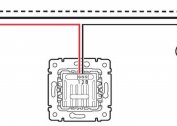

The design has slight differences, but the principle of operation is the same. The most primitive model are two-lip press tongs. Visually, they are very similar to pliers, but with a relief matrix of sponges. They can be an integral part of the housing or removable. It is used to connect terminal lugs and sleeves to each other.

The four- and six-sided press tongs are equipped with several jaws that create a round grip when squeezing the handles. This leads to the fact that the compressing element is subjected to pressure from four or six sides. The compressed sleeve takes a square or hexagonal sectional shape. They create a reliable connection with a tight fit of the required surfaces, this prevents moisture and air from getting into the contacts.

- Two-sided

- Hexagon

- Tetrahedral

How to properly operate the hydraulic crimp for cable lugs

The first use of a crimping tool is often accompanied by the creation of poor-quality and unreliable connection of the tip or sleeve with the wire. Also a common problem - a correctly executed crimp hides poor contact. There are two common causes of this phenomenon.

Terminal shape not maintained

The mismatch of the size of the openings between the jaws of the device and the size of the sleeve, tip is accompanied by the inevitable distortion of the squeezed segment. Before we begin to perform work, it is necessary to try on. It is also worthwhile to carefully monitor the tight entry of the bare and stripped core into the holes of the sleeve or tip shank.

A single core or group of them should enter the connecting part with a slight tension. If there is any doubt about the quality of the work performed, it is recommended to practice on small pieces of cable. After crimping with hands, the strength of the joint is checked. If even slight deviations from the norm are observed, the crimping should be repeated again.

Twisting stranded wires before crimping

Such a problem can arise if a person has the habit of twisting the veins. They do this, as a rule, before manually soldering the connecting elements or insulating the wire. But it is worth noting that this can not be done.

You can verify the negative effects of twisting in a simple way. It is enough to squeeze a small twist of multicore cables with pliers and see for yourself the deformation and damage to the integrity of each wire.

Key Benefits

The advantage of using the tool is that the matrix of ticks provides such a snug fit to the vein of the tip that moisture and air are not able to penetrate it. This prevents oxidation.

Special attention deserves a large assortment of tools in all construction stores at an affordable cost. Depending on the configuration and the ability to change the sponge, the price will change. In the long term, it is recommended to give preference to press pliers with replaceable jaws.