PVC pipe for electrical wiring is an effective means of protecting communications from external influences. In accordance with the requirements of SNiP open installation of power cables is prohibited in buildings made of solid wood and panels. In addition, the houses are shrunk, there is a chance of the walls getting wet, which can cause a short circuit. The use of electric PVC pipes reduces the risk of damage and destruction of communications to a minimum, which ensures the safe operation of the building.

The advantages of the location of the wiring in the pipe

Installation of wiring is one of the stages in the construction of administrative, utility and residential buildings. The laying method depends on the materials and the thickness of the supporting and internal structures. These factors determine the money spent, time and effort. The right choice allows you to equip the building quickly and inexpensively.

The use of plastic pipes for wiring gives the following advantages:

- Arrangement of premises built from combustible materials - wood, polymers, foam fillers. Even if the cable ignites, the fire will remain in a confined space.

- No need for additional protection. Vinyl tubes for wires reliably protect them from pressure, dampness, insects and rodents.

- Convenience of diagnostics of the conductor when it is placed in a hidden way, including in concrete. Ease of extraction and subsequent installation of a new line without destructive work.

- Prevention of accidental cable damage during repairs or redevelopment of real estate. The primary load is assumed by the tubes for electrical wiring.

A wide range of products made of polymers allows for the laying of communications by any means, choosing the material that is suitable for one or another criterion.

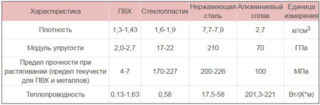

Characteristics of electrical PVC pipes

When purchasing pipes for electrical wiring, it is necessary to take into account the upcoming conditions for their operation, which are determined by the mobility of the walls, humidity and current strength on the line. On sale are models that are designed for domestic and industrial use.

Polymer pipes for cable wiring have the following technical characteristics:

- isolation with direct current - 2000 V;

- maximum impact strength - 2 kN / m;

- operating temperature range - from - 30 ° С to + 65 ° С;

- stretching to break when stretching - 30%;

- resistance to mechanical impulses - up to 6 kJ;

- insulation resistance - from 100 MΩ;

- specific weight 500-700 kg / m³;

- fire resistance - 600 ° C;

- minimum bending radius of corrugated products - 3 diameters;

- internal section - 10-200 mm;

- unit length 2-25 m;

- wall thickness - 0.8-2.0 mm.

High operational properties of the material determine a wide range of its application. PVC pipes for electrical wiring are used for mounting internal and external channels, including in open space. If the parameters are compatible, along with power cables inside the mains, it is allowed to stretch communication lines, television, the Internet and signaling.

Types of material

Vinyl-plastic pipes for electrical wiring are divided into several categories based on the composition, strength and degree of flexibility.

These types of products are distinguished:

- Smooth. They are rigid girders of circular cross section with smooth internal and external walls. Designed for installation inside concrete walls, on their surface and in the ground. They are highly resistant to impact and pressure. According to the operating conditions are divided into light, medium and heavy.

- Corrugated. Differ in a variable section due to the presence of folds. Due to this design, products can bend, stretch and contract. They are used for arranging curved sections, both outside and inside the walls. Depending on the installation features, conventional or reinforced steel spring products are used. Depending on the section, the length of the bay can be up to 200 m.

- NPVH. Unplasticized polyvinyl chloride (PVC-U, vinyl plastic). The material does not contain plasticizers, it is characterized by high strength, high melting point and the ability to self-extinguishing. Wiring is carried out in the most fire hazardous places, where there is a risk of channel destruction from mechanical influences.

The choice of material is determined on the basis of the analysis of the conditions of its forthcoming operation.

Range and characteristics of products

Manufacturers produce a wide range of polymer pipes, which differ in a number of characteristics that determine the scope of their application.

Depending on the type and diameter of the product can be used to equip such structures:

- for lighting devices - 1.6 cm;

- for sockets and switches - 2.0 cm;

- for shields and distribution boxes - 2.5 cm;

- for broaching between floors - 3.5-4.0 cm;

Smooth PVC pipes for electrical wiring are available in sections, the length of which is 200-600 cm. Corrugated products are folded into bays. Depending on the diameter, the length of the corrugation varies between 25-200 m.

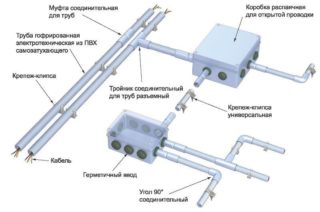

When installing the channel to give it the desired configuration, the following fittings are used:

- couplings;

- tees;

- angles;

- boxes;

- clamps;

- staples.

During the production process, pigments are added to the product, which color it throughout the volume. This technique is needed for marking the material.

So apply the following options for coloring polymer products:

- PVC - gray;

- PND - black;

- Ppr - blue;

- reinforced corrugation - red.

Thanks to this solution, the selection of goods and line maintenance during operation is facilitated, since the material is easily identified visually.

Benefits of PVC Pipe Wiring

A plastic pipe for cable wiring has a number of significant advantages over metal analogues.

- The polymer does not conduct electricity. Even when touching a bare wire, there is no risk of electric shock. The channel does not need to be grounded.

- Non-combustible material. It tolerates heat and exposure to open flames.

- Ease. Transportation and installation of products is not associated with the application of significant effort.

- Resistance to corrosion. Plastic retains all its characteristics in a humid environment.

- Resilience and flexibility. The links can be given any shape during installation by open and closed methods.

- Low thermal conductivity. Pipes protect the substances surrounding it from heat coming from the cable.

- Preservation of dimensions when temperature changes. The material does not taper or expand when exposed to heat and cold.

- Long term of operation. For high-quality models, it is 100 years old. Rodents and insects are not interested in PVC and avoid it.

- Affordable cost. The price of the material is 5 times less than that of analogues made of iron.

- Presentable appearance. Products fit well into any interior, especially in the loft style.

- No need for complex connections. Docking of links and fittings is carried out in sealed sockets.

Among the disadvantages of the material is its lack of strength and instability to ultraviolet radiation.

Installation Rules

When laying a plastic pipeline for cable lines, the following rules must be observed:

- The leaky route is only for internal structures, as it provides exclusively mechanical protection.

- The distance of the channel from the heating devices should be at least 10 cm. At the same time, it should be placed lower to prevent heating.

- Connecting the wires inside the pipes is prohibited. You need to do this in special mounting boxes.

- When the line is located in humid conditions, the joints are sealed with rubber gaskets and silicone.

- Fastening products to the bearing surface should be carried out using metal clips.

- When the pipes are located in the gates, before closing them with the solution, it is necessary to securely fasten with brackets.

- During laying, it is necessary to avoid the formation of creases, as this will complicate the subsequent broaching and maintenance of the line. When cornering, use knees or corrugated inserts.

With regard to safety measures, it must be borne in mind that the exhaust cable is in a stressed state, and if handled carelessly, it could injure your hands.

DIY installation

To carry out the installation of PVC tubes, such tools and materials will be required

- hammer drill;

- Bulgarian;

- roulette;

- level;

- screwdriver;

- knife;

- pliers;

- insulation tape;

- dowels;

- fasteners.

The installation technology is as follows:

- Work should be carried out at an air temperature not lower than + 5 ° С so that the material retains flexibility and elasticity.

- You need to measure the segments with a margin of 10%, so that there is a reserve for bends and trimming.

- After cutting the plastic, it is necessary to attach the probe to the walls of the pipe so that it is not pulled inward. Only after this can you bite the wire.

- Before pulling the cable, the wires must be twisted so that they do not cling to the inner walls of the channel. When connecting to a cable, its bent end must be straightened.

Features of the installation of corrugated pipes:

- frequent arrangement of clips, as the products are prone to sagging;

- strong tension is contraindicated - this reduces the strength of the channel;

- regardless of the laying method, it is conducted only in the vertical and horizontal direction.

Subject to the rules for handling plastic pipes and the technology of their installation, a strong, reliable and durable construction is obtained.