In modern housing, a large number of household appliances of different capacities that operate on electricity are used. For this reason, home wiring has many branches. All individual sections must be correctly and reliably fixed in order for the power grid to work efficiently. When installing conductive cables and wires, they use the rules and recommendations established by the PUE.

Basic rules for laying wires and cables

The safety and reliability of the entire electrical network in the apartment directly depends on the rules for wiring. To create a high-quality power network, the following requirements must be observed:

- For the premises, especially in a new building, a project for the supply of electricity is necessarily created. The layout shows the wiring diagram, the necessary materials, the installation location of the shield, junction boxes, sockets, switches.

- Calculation of the cross section of conductors, the choice of cable material. It is better to choose a copper conductor. The best budget option - products brand VVG.

- The use of machines to turn off the power in case of emergency. Each device group has its own circuit breaker. For powerful electrical installations - 25 A, for sockets - 20 A, for lighting, a nominal value of 16 A. is enough

- A number of household appliances require wiring along separate lines. These are electric stoves, powerful consumers of electricity, lighting, sockets.

- The main shield should be mounted at the entrance of the main cable to the room. Access to it should not be complicated for inspection and possible repairs.

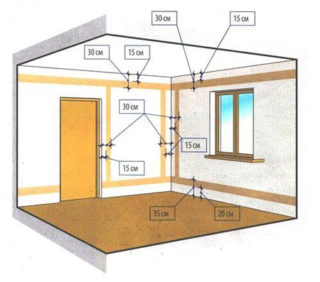

- It is recommended to observe the norms of SNiP for the placement of sockets and switches.

- Wires are laid vertically or horizontally in closed channels. There should not be intersections.

- Conductors must fit snugly in the groove for easy repair. Single wires must be fixed along the entire length at a distance of 90 cm. Cable bundles are fixed every 50 cm. Horizontal lines should be installed at a distance of 15-20 cm from the floor and ceiling and 10 cm from corners and openings.

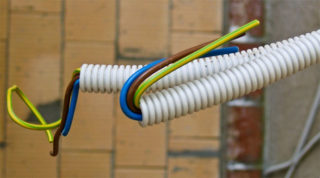

- Hidden lines should be laid in corrugations or pipes.

- The installation procedure for the wire connection rule must be followed. Particular attention should be paid to the contact of dissimilar wires (copper and aluminum).

During installation, it is absolutely necessary to disconnect the room. All work is performed in compliance with safety regulations.

Preparatory work

All materials should be prepared in advance. It is necessary to measure and cut the required number of cords, cables, pipes, sockets, junction boxes, fasteners. A suitable tool is selected - a puncher acts as the main one. You will need rifled crowns for drilling, a screwdriver, an installation tool.

When everything is prepared, the laying method is selected and the installation of the wiring begins. How to fix the cable correctly depends on the laying method.

Criteria for choosing a laying method

How to lay the wiring in the house is determined by various factors:

- environmental conditions;

- Placement

- power network diagram, wire sizes and cross-sections.

Environmental conditions include temperature and humidity. These metrics may affect product integrity.If the insulation is damaged due to improper selection of the conductor for climatic conditions, the risk of electric shock or fire to a person increases. Each cable has its own operating conditions, which must be fulfilled. There should be rubber gloves on the hands, the entire tool should have insulated handles.

The installation method, safety and ease of use depend on the choice of the installation location. An important point is the ability to check wiring for operability.

Cable fixing for different types of wiring

The type of wiring, the category of the apartment, the material of the building affect the way the wires are installed. There are two ways of laying - open and hidden. Each method has its positive and negative features, and each uses its own fasteners for wires to the wall.

Open wiring

Open wiring is usually selected if it is not possible to make hidden. Laying of wires is made in special cable channels and boxes. The wires are fastened with clips on the walls and ceiling. The disadvantages include the visual component - the wires are visible and may not fit into the interior, which violates the aesthetics of the room. The main advantages are ease of installation, high speed of implementation, access to wires.

Most often, open wiring is used in the following cases:

- Creation of the electric network in auxiliary premises. These include garages, attics, basements.

- Lack of cable channels in the room.

- Design a living room in a retro style or another, which fits open wiring.

Regardless of the area of use, the wires can be fixed in various ways.

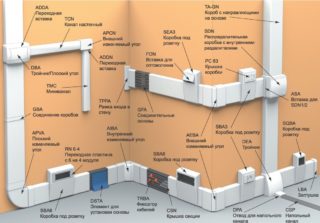

Decorative boxes, also called cable channelsare created from fireproof polymer. They are widely used in offices, wooden houses and cottages.

Products are long boxes with a lid, which is attached to the base with side latches. They have different sections - triangular, rectangular. There are also segment-type channels designed for installation on an unprotected floor mount.

Inside the channel, there may be partitions allowing the formation of separate sections for harnesses.

The wiring requires the use of various additional elements that allow you to attach the channel:

- angles;

- end caps;

- adapter parts;

- butt pads;

- bases for mounting switches, sockets, sensors.

The cable channel has good aesthetic properties, is easy to assemble and securely fixed. It protects the conductors from external influences, including mechanical, throughout the entire life cycle. The main mount is a screw that is screwed into a pre-installed plastic box. The wire is fastened to the wall at a distance of 50 cm.

One of the most common types of holders are plastic and metal. staples. They are a small part that has a recess for a round cable and a hole for fasteners. On plastic products, the lock is already installed in the housing. There are different sizes.

Metal appliances can be mounted on a clamp and clamp. The latter can be single and double-armed.

The functional analog of brackets is dowel clamp. The difference lies in the mounting method. To mount the clamp, a hole is first made, then it is put on the cable and inserted into the hole made. If the wall plug is installed on the wall, the function of a plastic air suspension is also performed.

Plastic clips also considered popular fasteners.They hold the cable due to the compressive action of the springs. The main fixing part is the screw, but products for adhesive mounting are also available. In size suitable for installation of a single conductor. They can also be used for fixing tubes and channels. There are different diameters.

Insulators They call small barrels with a circular groove, which is offset from the center, and a hole in the middle for the bolt. Due to the smooth edges of the housing, the insulation is additionally protected from damage. Outwardly look aesthetically pleasing. Previously, they were made exclusively of ceramics and were white, but now the color scheme has expanded due to the popularity of the design of the premises in retro style.

The most common use is fixing twisted cable. The recommended distance is 50 cm, but it can increase to 80. The selection depends on the degree of sagging of the conductor.

The universal fastener is cable tie. It is often used as part of other fasteners. It is a plastic strap with a central lock. There is a corrugated part on the belt, which allows you to securely fix the end of the screed in the lock and prevents it from slipping out.

Such fasteners are often used when laying out wires and pipes on cable trays. The main advantage is ease of use.

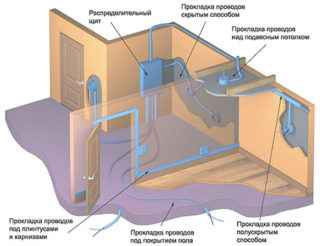

Concealed wiring

In case of hidden installation, cables are not visible to the eye. They are installed in the wall in special strobes. This type of gasket is actively used in the presence of suspended and suspended ceilings. Thanks to the installation in the wall, aesthetic requirements for the clips are not imposed. It is carried out in all rooms of the apartment (kitchen, bedrooms, living room).

The platform with the mounting hole is the easiest fastener. It is a plastic part with one or two eyes on the front side. After mounting the frame area, the conductor can be fastened with ties.

On sale you can find sites with an integrated plastic clamp. They are used less frequently. The platform itself can be attached to glue or a screw.

Dowel clamp represents a combination of the expansion bolt shield with an assembly platform. Such a device involves the use of a separate screed, but there are products with an integral component. In order to improve the fixation strength, instead of a notch, ribbing of the rod in round sections can be made. The fastening becomes reliable due to the fact that the dowel is clogged into the hole with a diameter smaller than the diameter of the fins.

For mounting conductors in gates quick drying formulations. The most popular are gypsum and alabaster. For fixation, it is necessary to cover the areas on the cable every 50 cm with a mixture.

The advantages include low cost, high installation speed and no need to purchase additional parts. The main disadvantage is the small capacity of the channel, which allows holding no more than two wires. Not suitable for laying corrugated pipes in strobes.

Clamps their design is similar to clips. The main difference is the fastening with a hard integrated clamp. There is a group design of clamps that allows you to fix several wires or plastic pipes at the same time.

Such devices are more expensive than classic clips due to the increased complexity of the design. They allow fixing the cable with different diameters, which is the main advantage. They can also perform the function of free support for the conductor.

Velcro is less commonly used in installation because of its inefficiency.

Features of the use of point mount elements

If external wiring from the post is made, it is better to use black plastic products.They are made of carbon black, which is a stabilizer and protects the conductor from the negative effects of ultraviolet rays. Plastic will retain its appearance and will not decompose.

A blunder is fixing a new cable to an already laid cable. This is due to the fact that the fasteners are designed for a certain weight and load, and an additional conductor will increase these indicators and lead to a failure of the connection. Especially often, such an error manifests itself when adding wiring lines in a panel house.

If one-foot metal brackets are placed, it is necessary to ensure that the fixing elements are placed on one side.