Modern electrical equipment makes life easier and creates an increased load on the wiring, which can not always cope with it. This is especially true for buildings that were built in the mid-end of the last century. Outdated cables and improper installation lead to overheating of the lines and short circuits. In order not to encounter such unpleasant and dangerous phenomena, you need to know what the wiring in the apartment is, the norms and rules of its installation.

Key Documents

Electrical installation rules apply to both government agencies and private developers. In accordance with their provisions, the initial stage of work should be a well-designed wiring diagram in an apartment in an apartment building. The paper must be agreed with the management company that issues the Technical Conditions.

Electrical installation rules apply to both government agencies and private developers. In accordance with their provisions, the initial stage of work should be a well-designed wiring diagram in an apartment in an apartment building. The paper must be agreed with the management company that issues the Technical Conditions.

The norms for wiring in residential premises are regulated by such acts:

- Rules for the installation of electrical installations (PUE) - planning and installation, connections and switching, the use of materials.

- GOST 31565-2012 - fire safety, prevention of fires.

- GOST 50571.15-97 - rules for laying lines, installation methods on various surfaces.

- SP 256.1325800.2016 - grounding and safety, insulation and dimensions.

- SNiP 31-110-2003 - instrument placement, distance and installation locations.

Violation of the rules for wiring in the apartment entails administrative and financial liability.

The importance of applying standards

Compliance with electrical wiring standards in the apartment is achieved by the exact implementation of the requirements of legislative acts.

The importance of their application is as follows:

- selection of conductors, the cross section of which corresponds to the power of consumers;

- elimination of the risk of electric shock to people;

- optimal location and proper selection of the required number of outlets;

- prevention of the risk of fire in the network;

- prevention of damage to household appliances.

If you strictly observe the building codes and regulations, you can correctly calculate the need and type of conductors, which helps to reduce the construction budget.

Key points of requirements and rules

The rules for laying electrical wiring cover a wide range of aspects of installation, from the choice of materials to the procedure for putting the structure into operation.

Minimum cable cross section:

- introductory - 4 mm;

- sockets - 2.5 mm;

- lighting group - 1 mm.

Number of conductor cores:

- single-phase line - 2;

- single-phase network with grounding - 3;

- two-phase supply - 3;

- two-phase network with grounding - 4.

Placement of sockets, switches and wiring at a distance from surfaces and objects:

Placement of sockets, switches and wiring at a distance from surfaces and objects:

- floor - 30-120 cm;

- panel joints - 20 cm;

- window and doorways - 10 cm;

- sewer and water pipes - 30 cm;

- sinks, bathtubs - 50 cm;

- heating appliances - 20 cm;

- electric stoves - 15 cm;

- gas lines - 40 cm.

Types of wiring:

- with isolation of one and several colors;

- copper and aluminum;

- with conventional and non-combustible coating.

Circuit breakers that are installed in the electrical switchboard:

Circuit breakers that are installed in the electrical switchboard:

- batch type;

- relay;

- fusible;

- electronic.

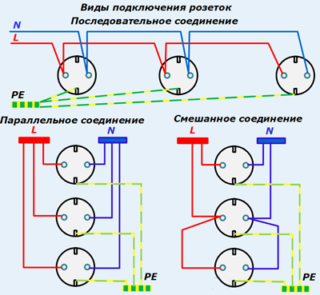

Line layouts:

- consecutive;

- parallel;

- combined.

Electrical installation requirements apply to residential and auxiliary premises, including loggias, balconies and vestibules.

Installation of concealed wiring

Concealed cable laying is carried out in buildings built of concrete, brick and gas silicate blocks. This approach is considered the safest, but time-consuming, since it is necessary to carry out a large amount of drilling and plastering.

Wiring requirements determine its installation in the base:

- In the walls. Previously, from the junction box to the hole for the outlet or switch, strobes are made. Grooves of a rectangular or triangular section can be cut. After that, wires or plastic tubes are attached to them, into which the cable is subsequently tightened.

- Under the floor. The event is carried out at the stage of construction or replacement of a wooden coating. Laying involves a minimum of effort. The disadvantage is that there is a risk of damage to the insulation by cockroaches and mice, which often wind up in the underground. Another minus is the large amount of work for the output of lines to the ceiling lamp and switches.

- On the ceiling. The best option is to pull communications into the voids of floor slabs. If this is not possible, strobes are made in the plaster layer, in which the wiring is walled. Cutting the base plate is prohibited.

When choosing a laying method, the financial side of the issue is taken into account. If you do the installation on the floor, the cost of an expensive cable will be large.

Installation of open wiring

Installation of open electrical wiring is carried out in buildings made of wood, panels, panels and other combustible materials. When designing, you need to take into account that the distance of the wiring from the ceiling should be at least 2 cm, and the floor outlets should be no more than 1 meter. When laying lines, it is forbidden to use nails, staples and screws to fasten the cable directly to the bearing surface.

Regulatory documents set the following mounting options:

- flexible corrugated tubes;

- rigid round and rectangular plastic profiles;

- threaded metal hoses;

- polymer cable channels;

- hollow split platbands and baseboards;

- steel strings;

- ceramic insulators.

Since such structures look unaesthetically on the ceiling, there are several ways to mask them. For this, tension structures, suspension systems made of gypsum plasterboard, plastic panels and metal battens are used.

Ways to install sockets and switches

Installation of sockets and switches, as well as wiring, can be performed in an open and closed way.

The first option is used to equip rooms whose walls are made of combustible materials or their thickness is insufficient for installation of mounting boxes (socket boxes). In some cases, such a decision is made to save time and energy during the construction process or in case of failure of previously laid wiring. Fastening is carried out directly on the bearing surface. The disadvantages of the outdoor installation are that the instrument enclosures 4-6 cm protrude above the surface of the walls and spoil the interior of the premises. In addition, the likelihood of damage or demolition of the product during careless movement, the transfer of furniture and large household appliances increases.

The closed method of mounting the outlet can be used in combination with all types of cable routing. Previously, holes are made in the wall into which plastic glasses are attached to the putty. After crystallization of the solution, the outlet is connected to the wires and its rigid fixation in a plastic box. If you do not take into account the difficulties of gating and drilling holes, this method is more reliable, practical and aesthetic.

Compliance with standards

When conducting electrical work in residential premises, it is necessary to comply with the standards established for them with respect to such parameters:

- Cross section lived.You need to choose conductors with the calculation of the maximum load that will affect them. When exceeding the permissible power, the metal heats up, which leads to the formation of smoke, melting of the insulation and the risk of fire.

- Laying lines. Fragments of the network can be located only in the vertical and horizontal direction, they should not cross each other during internal installation. Groups of outlets should be placed at the same distance from the floor.

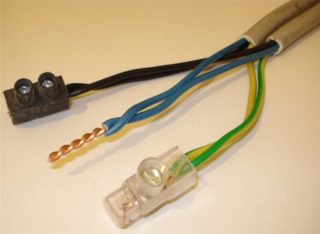

- Commutation. The main rule is the ban on direct connection of copper and aluminum conductors. To do this, use an indirect connection in a bolt with a nut, tires or spring terminals. Wires made of one metal can be twisted with subsequent insulation.

- Location. The slightest likelihood of mechanical damage, melting of the wiring elements and the ingress of water into them must be excluded.

Compliance with standards is the foundation of safety and durability.

Rules for different types of wiring

When choosing wiring for equipment of premises of various types, the rules set out in GOST 12.1.044 should be observed. For residential buildings, you need to use three-core cables with 1-2.5 mm copper conductors. The insulation must be non-combustible and smoke-free when heated. The VVG-Pngd, VVGzngd, Flame-X, N2XH, YnKY brands correspond to these parameters.

For the arrangement of rooms made of non-combustible materials, the use of simple conductors is allowed without any restrictions. A powerful line equipped with an RCD must be extended to powerful consumers operating in a continuous mode.