Operating electrical appliances must be grounded. Depending on the purpose, it can be working or protective. The first is for the correct operation of devices, and the second is for protecting people. The principle of operation of one and the second is different.

The main goals and objectives of grounding

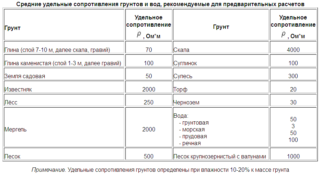

The soil is able to neutralize electric current, since the degree of its voltage is zero. Resistance is the main indicator of a grounding device by which it is possible to judge its quality and ability to fulfill its purpose. The specific resistance depends on the composition of the soil, the presence of chemicals in it - acidic or alkaline, moisture, friability. Depending on the composition of the soil, you may need to use some special grounding kit or a complete replacement of the ground for the correct operation of grounding devices.

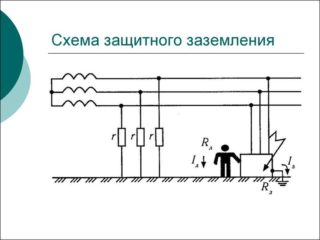

Grounding is the connection of any device, electrical installation or part of the network to a grounding device. It is a grounding conductor and grounding conductors through which current flows into the ground and is neutralized.

There may be several earthing switches. In a distributed circuit, they are located around the perimeter of an object whose electrical network must be secured. The conductive part (grounding conductors) are usually made of metal. Grounding electrodes are brought to them, which have direct contact with the soil.

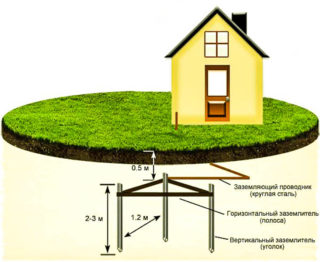

The grounding device is mounted on a circuit. The ground loop is a series of electrode conductors that clog into the ground. Their length is 3 meters, they are located at a small distance from each other. A horizontal metal strip is used as a compound, which is laid in the soil to a shallow depth of up to 1 meter. The connection to the electrodes is carried out using conventional welding. In special grounding kits, parts of the equipment are threaded, which does not affect the working properties.

Working grounding is necessary in the following cases:

- Protecting equipment from static electricity. Processes that occur in nature, such as lightning, can affect the current flowing in the circuit, as a result of which equipment can be damaged. Electrodes installed in the ground discharge excess current.

- Network protection against short circuits.

- Surge protection.

An example of a working ground is a lightning rod that is connected to electrodes. Especially relevant in generators, transformers.

Protective grounding principle

Protective grounding is a set of measures that are aimed at protecting equipment and the people who work with it. It is used to eliminate electromagnetic interference arising from a nearby device, as well as to neutralize interference during switching in the power circuit.

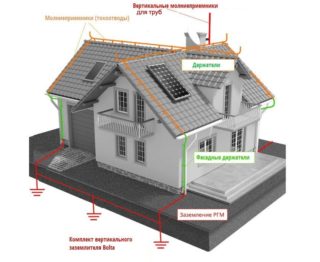

Lightning Protection

The air medium is a section with high resistance, but the discharge has a power exceeding this resistance, therefore it breaks through it. On the way from the upper layers of the atmosphere to the earth, lightning selects the areas with the least resistance - wet areas, walls, trees and drops of water.This explains the fact that discharges often fall into the tree - it has less resistance than the air around it. When it enters the building, the current also passes through the areas with the least resistance - these are metal pipes, electrical appliances or their metal parts, wet walls. If the device is not grounded, touching it at the time of charge passage can be fatal.

When a lightning rod is installed on the roof, the charge enters it, and then it moves to the ground and is neutralized. It is important that the currents do not propagate inside the object, so the materials that are used to equip the ground have a low resistance. According to the rules, it should not exceed 4 ohms. The lightning conductor itself must be connected to the electrodes in the ground.

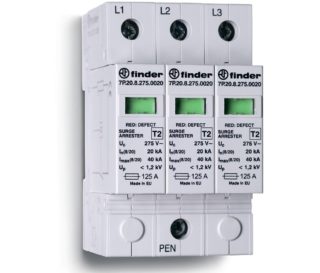

Surge Protection

Electronic equipment is sensitive to power surges or powerful electrical installations operating in their radius. Sudden lightning strikes nearby can damage the electronics.

As an example: during a thunderstorm, an excess charge may occur in the copper cable with which the houses are connected and through which current flows. A charge with an increase in its size can destroy the cable. In this case, an SPD is placed on the power line - a surge protection device so that excess charge is pitted into the ground.

People protection

Cases of devices, all metal elements are capable of conducting current. If you touch an ungrounded device in which static electricity has accumulated, you can get a strong blow. This will affect primarily the cardiovascular and nervous system. Rubber shoes, rubberized gloves, an absolutely dry room help reduce the impact, but people rarely walk around the apartment or office in rubber boots. Connecting the third wire to the instrument housing, and then connecting it to the electrodes allows you to utilize excess current into the ground.

In old private and multi-apartment buildings, grounding measures were not carried out, therefore, all electrical appliances pose a potential danger to people.

Home-made devices can look like this: a wire is connected to the body of the device, which is displayed on the street and connected to a metal product driven into the ground (pipe, corner, bucket, fittings). These products are good conductors of current, unlike the human body, so the current selects the metal and goes into the ground.

Difference of working grounding from protective

Working and protective grounding according to safety rules should not be combined with a water circuit. During atmospheric discharges, electrical appliances can be damaged, and protective earth will not work.

Working and protective grounding according to safety rules should not be combined with a water circuit. During atmospheric discharges, electrical appliances can be damaged, and protective earth will not work.

In the functional (working) grounding circuit, all current-carrying structures are connected to electrodes installed in the ground. For the correct operation of the working ground, fuses are also used that take voltage on themselves and fail.

Working grounding is equipped in the event that the instructions of the manufacturer and the requirements that protect this device are attached to the devices.

There are more requirements for a protective grounding device, since it has more important tasks: saving people's lives.

| Purpose of the working grounding device | Purpose of protective grounding |

| High power appliances | Three-phase appliances with a power of less than 1 kW |

| Electronic Sensitive Equipment | Single and two-phase devices that do not have contact with the ground |

| Medical devices | Equipment with a capacity of more than 1 kW |

| Electronic technology that is a carrier of important information | In fused circuits with neutral conductor |

The most reliable grounding is provided in the house electrical circuit. Cables that fit each outlet must be three-wire.The third core connects to the ground and removes static electricity, and also prevents short circuits and lightning from entering the building.

Protective Earth Requirements

For grounding installations to fulfill their functions, they must comply with certain parameters and the instructions of the equipment manufacturer.

For grounding installations to fulfill their functions, they must comply with certain parameters and the instructions of the equipment manufacturer.

Nuances that affect the functionality:

- Resistance to soil due to its physicochemical characteristics. Wet clay, graphite chips, peat, salt marshes or sea water conducts the best current. Worse - dry sand or hard rocks - granite, crushed stone, quartz, asphalt, concrete.

- The area of contact of the ground electrode with the soil. The larger the area, the more favorable conditions are created for the flow of current, the faster this happens. You can increase the area by installing a larger number of electrodes along the contour of the building. In this case, they are connected together with a steel plate into a single unit. If you increase the size of one electrode, the total area will also increase. The installation of a vertical metal contour helps to increase the area if the lower layers of the soil have more resistance than surface ones.

Since it is difficult to achieve ideal soil resistance, devices are created based on its characteristics. Each electrical installation has its own resistance standards for grounding devices. For example, for an electrical substation with a voltage of more than 100 kW, the resistance should not be more than 0.5 Ohms, and for a home network with a TT system, as well as the use of automatic shutdown, up to 500 Ohms.

Metal earthing switches shall not be coated with paintwork materials. Sometimes, as the grounding device, the underground part of the building with metal structures is used - electrically conductive concrete with reinforcement inside. Do not use gas metal pipes to solve the grounding problem.

According to the Electrical Installation Rules, the following are subject to grounding:

- Networks with voltage higher than 380 V.

- Particularly hazardous and outdoor installations.

Parts of equipment subject to grounding and grounding:

- Enclosures for electrical equipment.

- Secondary transformer winding.

- Drives of electrical appliances.

- Switchboards, cabinet frames.

- Metal construction equipment.

- Iron sheath cable.

If the voltage does not exceed 42 V AC or 110 V DC, grounding is not required.

Household grounding

Most domestic accidents involve touching a device that has insulation damage. The human body in this case is a current conductor. Electric cooktops, washing machines and dishwashers, radiators, microwave ovens, boilers, PCs, dishwashers - all these are metal structures that conduct electricity well and without grounding can be harmful to health.

Short circuit - this is the contact of the phase and neutral wires in the network, which leads to the operation of emergency protection and disconnection of the device from power. Most often, it is not a short circuit, but a leakage of current that accumulates in the housing of household equipment. This may result in electric shock.

For human safety, it is necessary to install sockets with grounding contacts. A three-wire cable must be connected to the outlet. With a two-core and three-core system, grounding is equipped in different ways - from the junction box or the electrical panel.

Do not use gas, water or central heating pipes as a ground electrode.

Grounding operation in case of electrical faults

Equipment malfunction means damage to the insulation and the occurrence of a phase in the instrument case.If parts of the equipment are energized, but do not have protection in the form of grounding and RCD, a person who is not aware of the danger may receive an electric shock.

Equipment malfunction means damage to the insulation and the occurrence of a phase in the instrument case.If parts of the equipment are energized, but do not have protection in the form of grounding and RCD, a person who is not aware of the danger may receive an electric shock.

In the second embodiment, the current leakage may not be significant, the equipment protection device will not respond to voltage and will not turn off the device. A person may receive a minor blow.

If the case is not grounded, but the RCD is installed, it will work 0.02 seconds after a person touches the device body. This time is not enough to cause harm to health.

The most effective circuit in terms of safety is the presence of grounding and RCD. If a current leakage occurs and it passes into the ground, the RCD reacts and turns off the device.

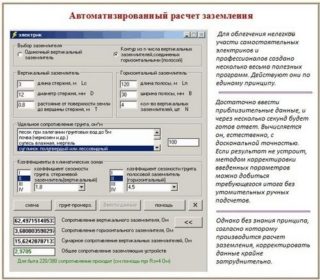

How is the calculation of the parameters of the main grounding elements

The calculation of the parameters of the grounding device is performed according to the formulas. The starting elements are:

The calculation of the parameters of the grounding device is performed according to the formulas. The starting elements are:

- soil resistance in this area;

- the length, thickness, diameter of the electrodes, as well as their number.

In practice, in all cases there are discrepancies with the intended work plan, since the soil index needs to be analyzed more accurately. It is practically impossible to do this: at 100 square meters, you need to drill about 100 mini mines up to 10 m deep to evaluate the soil layers, its composition and the inclusion of elements - clay, limestone, sand and other components.

The installation of grounding devices is carried out according to the main principle of grounding: the presence of a margin of safety, having averaged values of the parameters. The lower the resistance, the better for all electrical appliances and people.

Grounding installation

Vertical electrodes more effectively perform their functions, as they can be installed at a great depth. With horizontal laying at a shallow depth, the resistance increases, especially in winter, when the upper layers of the ground freeze.

For electrodes, pins are used, the length of which is more than 1 meter (usually 1.5 m). Such structures are easy to hammer into the ground with a conventional hammer, the connection is made in a horizontal plane at least 0.5 m in depth.