Frequent failure of various types of lighting lamps should not go unnoticed. There are several reasons why the light bulb burned out, therefore, to identify and fix the problem, you need to carry out a set of measures.

The reasons for the constant burnout of bulbs

If different types of lamps fail, you need to identify and eliminate the cause. In the absence of skills and the appropriate tool, it is better to contact a qualified electrician.

Why does the incandescent lamp burn out

Every year, incandescent lamps are in less demand due to low competitiveness. In comparison with analogues, the only advantage of incandescent lamps is low cost, but most often difficulties arise when using them.

Why incandescent bulbs often burn out:

- purchase of a lamp made of materials of dubious quality;

- power surges;

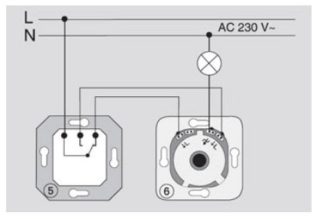

- Incorrect connection scheme.

The durability of the incandescent lamp is also affected by the presence of a backlight on the switch.

Blown halogen lamp

In modern apartments, spotlights with halogen lamps are often used. They have many advantages, the main one is a long service life. Among the causes of frequent burnout, it is worth highlighting:

- Halogen lighting devices are very moody if they are not installed correctly. Fail quickly when using the wrong wiring diagram.

- Poor connection of spotlights to power wires.

Substandard lighting fixtures, for example, Chinese budget chandeliers, sconces, etc. deserve special attention. The most common failure - as a result of the work, the cartridges overheat and lose their elasticity, which leads to the constant burning of lamps.

LED bulb burned out

LED lamps are in great demand. With slight voltage fluctuations, the service life of lighting devices can reach several years. They can often burn out for the following reasons:

- Burnout of a single LED in a series circuit. The lamp goes out due to an interruption in the electrical circuit.

- With parallel-serial connection of LEDs, one chain burns out. At the same time, the lighting device does not completely go out, but only shines weaker.

- Stroboscopic effect: continuous flickering due to an incompletely burned diode.

There are not many reasons for the frequent burnout of LED lamps, you can identify them yourself.

What determines the operational life of lighting devices

Lamps can quickly burn out due to the poor quality of the materials used and the harmful effects of external factors. If the reasons are not related to inadequate product quality, the service life depends on the characteristics of the wiring and its components, as well as the operating mode.

Mains voltage level

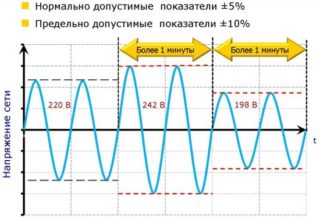

Lowering or raising the voltage beyond the permissible limits is the most common reason for the failure of electrical appliances. GOST 13109-97 states that the voltage for a single-phase network should be in the range 198-242 V. The error should be no more than 10%.

Lowering or raising the voltage beyond the permissible limits is the most common reason for the failure of electrical appliances. GOST 13109-97 states that the voltage for a single-phase network should be in the range 198-242 V. The error should be no more than 10%.

The rated voltage of incandescent lamps is 240 V.To prevent rapid combustion, it is necessary to additionally install stabilizers that will help to protect lighting fixtures and expensive household appliances.

Each switch can be equipped with a special protective unit, which prevents sudden voltage drops that occur during switching on and during operation.

Frequent inclusion

At the switched off lighting device, the filament is chilled. When you turn on the lamp, the resistance is lower when compared with a red-hot thread. Turning the light on and off too often in the room reduces the life of all types of lamps due to a violation of the integrity and damage to the filament under the influence of inrush current.

Low-quality cartridges

The problem that can be solved independently is the weakening of contacts in the cartridge. When replacing an old lamp with a new new one, you need to carefully inspect the base and inside of the cartridge. Do not ignore the appearance of soot and areas with specific darkening.

When operating a screw-type cartridge, you need to turn off the power supply to the house and make sure that there is no voltage. After that, with a special flat-head screwdriver with a rubberized handle, the central contact petal is carefully bent. Such simple manipulation will improve contact with the lamp and minimize the likelihood of repeated burns.

Cartridges are made of plastic or ceramic. The second option is more preferable.

Bad switch

During operation, one- and two-key switches wear out, regardless of design features. The most susceptible to wear are the contacts, which are prone to burning with frequent use of keys.

If the contacts burned out in the switch, it is possible that the lamps will quickly burn out or flicker. The dismantling and repair of the old circuit breaker will help solve the problem, possibly replacing it with a new one. You can also install a dimmer - a device that eliminates the possibility of power surges when turned on. With it, you can adjust the brightness of the lighting.

Local repair of the device includes a complete inspection of the wires for short circuits, oxidation of contacts and discharge. Identify the problem will help melted or blackened areas on the wiring.

Bad contacts

The cause of the burnout of the bulb may be a malfunction of the wiring. First, the connection on the distribution panel is checked, and the correct tightening of the screw connection (if necessary) is carried out.

If every time the lamp burns out, it knocks out an automatic machine or plugs, you need to check for compliance with the wiring power and household devices. If insufficient power indicators and a significant wiring malfunction are detected, the electrical device must be replaced.

Further, it is important to inspect the connections of the wires located inside the junction boxes. Melted or darkened areas require stripping and tightening of joints that are weakened. If there is an insulating twist of doubtful quality on the wiring section, it must be replaced or installed with a special connector.

Vibration, temperature and mechanical stress

In the process of using electrical appliances, strong vibrations and shocks can occur that significantly reduce the life of the lighting fixtures.

To extend the operating period, it is important to minimize mechanical stress, including shocks and shaking.

LED lighting devices are not afraid of mechanical and thermal influences, are resistant to voltage surges and have a long service life.

The operation of lighting devices at low temperatures provokes strong thermal drops of the filament, which also negatively affects the work.

How to prevent frequent burnout of bulbs

There are several preventive measures that will extend the life of the lamps at home.

- Use diodes to protect the lamps. As practice shows, diodes practically do not affect the quality of lighting, and the service life is significantly extended.

- Regular cartridge prophylaxis. It is recommended to periodically inspect and protect the contacts, if necessary, tighten the connections.

- If possible, reduce the effects of vibration and shocks, especially when it comes to incandescent lamps.

Electricians with many years of experience recommend installing bulbs of the same power in the chandeliers, this ensures uniform load distribution.