The AP-50 circuit breaker is used to protect electric motors and other electrical installations from overload and short circuit incidents. They are also used to start and turn off engines and electrical circuits.

AP-50 assault rifle device

Products in this series are available with two and three poles. The devices from the first group are designed for constant electric current with a nominal voltage rating of up to 220 V and alternating current up to 500 V (50-60 Hz). Three-pole models only work with alternating current (the parameters are the same as for bipolar devices). The electric filling of the machine is placed in a plastic case, which includes a removable front panel, bottom and main part.

The switch has 4 technological units:

- a control mechanism based on free trip, with instantly activated buttons on and off;

- cameras that extinguish an electric arc (located at the bottom of the device);

- ultra-high current releases - thermal (covered from above with a protective plate of textolite) and electromagnetic;

- contact system, including stationary and movable elements.

The magnetic release is responsible for the ultrafast misfire in the area of short-circuit currents, and the thermal one is switched on in the overload zone, and the larger the current, the shorter the response time. The factory calibration of the releases is carried out at an air temperature of 35 ° C. The device also has inputs and outputs for cable installation. It is mounted on a vertical or horizontal base with a pair of screws. There is enough space inside the case, which allows you to install additional elements - for example, an extra-low voltage release (although models are available in which it is mounted at the factory) or block contacts. Under the buttons of the control mechanism, a lever is mounted that controls the susceptibility of the releases.

Among the AP-50 models, there are none equipped with block contacts in general, having one contact or two. In devices not equipped with such a component, you can put it yourself.

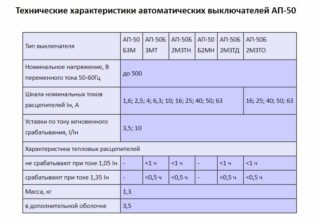

Specifications

In good condition, the machine is able to tolerate mechanical influences in accordance with category M7 specified in GOST 17516.1. The device is completely protected against moisture, therefore, during operation, care must be taken to prevent its penetration into the housing or work units. Do not place the device in a room with high humidity, in a very hot place (40 ° C and above), where dew falls or frost settles, and also in places where the rays of the sun or the radiant energy of heating appliances penetrate.

In good condition, the machine is able to tolerate mechanical influences in accordance with category M7 specified in GOST 17516.1. The device is completely protected against moisture, therefore, during operation, care must be taken to prevent its penetration into the housing or work units. Do not place the device in a room with high humidity, in a very hot place (40 ° C and above), where dew falls or frost settles, and also in places where the rays of the sun or the radiant energy of heating appliances penetrate.

At room temperature (15-25 ° C), the characteristics of the thermal release are as follows:

- with a current of 1.05 In for an hour of operation does not occur;

- contacts open in half an hour at a current of 1.35 In;

- if a 6 In load is sent to one of the poles, the overload release will be active for 2-15 seconds;

- After disengaging, the device can be switched on again the next time after 2 minutes (during this time the mechanism cools down).

Automatic machines are imprisoned for a limited number of on and off (50,000). The maximum switching capacity for currents up to currents up to 10 A is 50,000, for 16-25 A - 25,000, for large values - 20,000. The current limit at which the device turns on is 10 A.

From time to time you need to clean the device from dust and dirt, check the position of the contacts (there should be no distortion). It is necessary to regularly remove dust and the space around the device.Dust has pronounced conductive properties and can easily lead to malfunction of the circuit breaker.

Current limit class (cutoff speed)

The technical documentation supplied with the device does not provide data on the cutoff speed. But this parameter can be determined during practical tests in commissioning organizations. A properly functioning switch generates a cutoff in 0.01-0.015 s. If the time exceeds 0.2 s, the device is considered defective. Given the significant movement of the core, the current limitation class for this group of devices is in the region of unity. In situations where this parameter plays a significant role, it is better to purchase a machine of another brand with high speed.

Response characteristic

The time-current characteristics of the AP-50 series vary depending on the current strength indicator. For In at 1,6,2,5 and 4 A, the response time for small digits of the current multiplicity (2-4) is shorter than for large In values, and for large overloads, on the contrary, it is slightly longer. Thermal releases at any current values are triggered by an overload of 1.5-3 times, and the reaction time varies between 70-300 s. Magnetic trip units at 3.5 In turn on more slowly (up to 60 s), and at 10 In they activate at eight times or more overload for a single number of seconds.

Operating principle

When a short circuit current or overload occurs in the phase, one of the releases comes into action, sending a signal to the rail, turning off the current and opening the contacts (it can work with any of the three phases). The extinction of an electric arc is based on its separation into parts and deionization by plates installed in the chambers. The maximum current can be adjusted using a special bolt. To access it, the device is turned off from the network, the bolts holding the cover are unscrewed and removed.

When a short circuit current or overload occurs in the phase, one of the releases comes into action, sending a signal to the rail, turning off the current and opening the contacts (it can work with any of the three phases). The extinction of an electric arc is based on its separation into parts and deionization by plates installed in the chambers. The maximum current can be adjusted using a special bolt. To access it, the device is turned off from the network, the bolts holding the cover are unscrewed and removed.

Manufacturers of circuit breakers AP-50

Machine guns are made at Russian and Ukrainian enterprises. Of the first, the largest manufacturers are the Kursk Electric Appliance Plant (its products are labeled as AP50B) and the Electrocontactor from Chelyabinsk, which makes some modifications to the design: square buttons instead of round ones, contacts for connecting to the network are located on the surface of the casing. In Ukraine, circuit breakers are manufactured by UTOS soft starter located in the city of Korosten in the Zhytomyr region.

Tests of the AP50 assault rifle

This procedure includes checking the operation of the two main releases. In the process, a current with different indicators of overload is applied.

Checking the thermal release AP50

As the device under test, for example, RETOM-21 can be used. It is connected to the extreme poles of the circuit breaker after connecting the poles in series. Testing is carried out by three types of current:

- 1.05 * In or 1.1 * In (where In is the nominal value) - when applying such a current, the device should not be turned off for an hour;

- 1.35 * In - current at which the trip should occur within half an hour;

- 6 * In - when applying such an overload, shutdown occurs within 2-15 seconds.

The procedure allows you to check the health of the machine when responding to various degrees of overload.

Checking the electromagnetic release AP50

This release is triggered when a tenfold overload arrives (10 * In, i.e. 500 A). Shutdown should occur in 0.1-0.2 s, with a longer reaction the device is considered defective.

AP-50 series instruments are well suited to protect networks from overload and prevent short circuit incidents. However, if the current limitation class is of great importance, it is better to choose a faster automatic machine.It is also important to comply with operating conditions - to prevent excessive humidity and water from entering the enclosure or inside the circuit breaker