The junction box belongs to the category of electrical distribution products used in the arrangement of wire lines indoors and outdoors. Its functional purpose follows from the name, meaning a device for disconnecting individual conductors. The presence of a removable cover in the box provides repair personnel with free access to the internal parts of the wiring, if necessary, changing the order of switching. In domestic networks, this device is used for the assembly of power buses and their subsequent wiring for specific consumers in the apartment.

Types of Junction Boxes

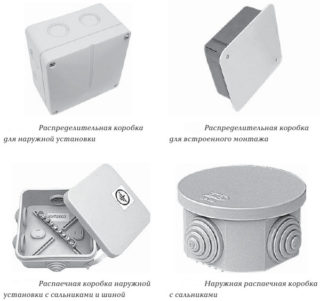

Different samples of electrical distribution boxes are distinguished by the installation method, as well as by the type of material used in their manufacture and by a number of other signs. According to the first of these criteria, they are performed in the following modifications:

- for internal or flush mounting;

- for outdoor installation (patch boxes).

The first type of installation products is placed in pre-prepared niches drilled into the wall with a special “crown” nozzle. Conductors brought to it are also mounted discreetly in specially prepared strobes for this. For outdoor installation, the distribution box is mounted directly on the wall or on a special plastic socket (plywood blank). For walls trimmed with plasterboard sheets, most often a hidden installation method is used.

By the type of material used, all known types of junction boxes for electrical wiring are divided into plastic and steel products. For the manufacture of the second variety, tinned sheet steel or aluminum alloys that are not susceptible to corrosion are used. In boxes having the most protected design, tight insulation from gaskets is provided, as well as a tightly screwed lid.

The metal case guarantees the safety of the conductors placed in it when ignited for a time sufficient to operate the protection devices.

The plastic enclosures of the electric skins are not as reliable as their metal counterparts. Despite this, they have the following positive qualities:

- oxidation resistance;

- good insulating properties (do not conduct electric current);

- ease and cheapness.

Junction boxes vary in their shape and can be square, round and rectangular. The round junction box is ideal for lines with few connections and open installation. With a large number of cores, it is more convenient to use rectangular plastic or metal products.

If internal mounting is necessary, a round box is considered more convenient, since it is easier to choose a niche in the wall for it.

The geometric dimensions of the boxes for wires depend on the total number of conductors and their cross-section.

Benefits of using a distribution box

Properly selected by type and correctly installed in the selected place, the distribution box provides the user with a number of advantages.

- With this approach to the organization of assembly nodes, there is no need to search for free conductors for the necessary commutation.

- Knowing where the electric outdoor distribution boxes are located, it remains only to connect the new device to the existing electrical wiring, using their internal wiring.

- Finding a location for flush mounting is also easy - to do this, you will need to examine the wall section above the outlet.

- Usually at a distance of about 3-5 cm from the ceiling, it is possible to find a whitened plastic box cover, which you just need to open.

- Inside you can create a reliable connection of conductors, guaranteeing high quality switching.

Due to the use of flush mounted distribution box, its presence does not violate the general interior of the room. If outdoor mounting is used, the bundle from the set of connecting conductors is laid in a decorative cable channel.

Internal arrangement and switching principle

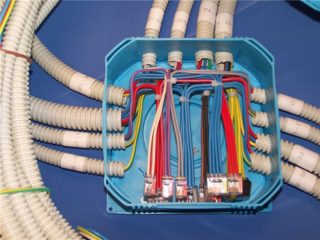

The internal space of a typical box is conventionally divided into 4 zones with external walls adjacent to them. Each of them has a perforated hole (usually a round shape) into which cable bundles are inserted. One of them comes from a switchboard with a linear circuit breaker and incorporates phase and zero conductors.

If necessary, wiring from two adjacent sides is wired from the switches and sockets located in this branch. Upon completion of all the required exceptions, the cable cores are looped out towards the adjacent section of the room.

When terminal boxes are installed in dead ends, the number of openings involved may be less.

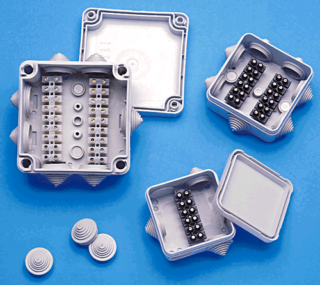

The dimensions of the internal spaces of the switchgear allow you to place elements of standard connectors in it.

Methods for connecting wires in a distribution box

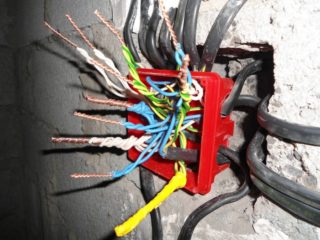

There are many options for connecting mounting conductors in a distribution box. The choice of a specific switching method depends on the material of the lead cores (copper or aluminum), environmental conditions, as well as on the cross section of the conductors.

Given the above factors, it is allowed to connect switchable wires inside the box by the following methods:

- simple twisting followed by soldering of the formed contact;

- by means of special terminal blocks;

- bolted connection;

- self-insulating clamps PPE or "nuts";

- “Wago” type spring terminal blocks.

Primitive twisting followed by soldering is used only in cases where conductors of homogeneous materials are connected. Copper and aluminum tires cannot be combined in this way.

Due to the use of soldering, twisting ensures a high quality of articulation and is usually used when space inside the box is limited due to the inability to place the connecting elements. The advantages of this method include the simplicity and cheapness of twisting, and the disadvantages are the complexity of dismantling and the need for an additional tool - an electric soldering iron.

Terminal blocks are ideally suited for arranging a reliable connection of wires of various materials inside a metal wiring box, for example. Products used for these purposes are made of plastic and have a contact brass sleeve with screws inside. After the wires are inserted on both sides by 5-7 mm, they are securely fixed with a screw clamp. The plastic case provides reliable isolation of contacts from the metal case of the box.

Bolted connection is a fairly simple but effective way of connecting conductors without direct contact. For its arrangement, you only need a bolt, three washers and a nut. It is prepared as follows:

- A washer is put on the bolt thread, and then a core of one of the conductors is cleaned from the insulating shell.

- One more washer is placed on top of it, onto which the bare end of the second wire is screwed in the same way.

- At the end of the contact design, a third washer is applied to the core, and then this entire assembly is clamped with a fixing nut.

The classic bolted connection is characterized by low cost of fasteners, ease of arrangement of joints, as well as the possibility of combining copper and aluminum conductors. The disadvantages include not very high-quality fixation of the ends of dissimilar tires and the need to close the connection with a sheath of insulating material. In addition, it is hardly placed within the wall box, which is explained by the large size of the bolted product used.

Self-insulating contacts are made in the form of a plastic cap, in which a special spring is placed to fix the bare ends of the conductors. The advantages of these connectors include a relatively low cost and the presence of flame retardant plastic in the design. Also noted is the simplicity of arranging a contact connection and a large selection of color shades for caps. The disadvantages of PPE include the low reliability of fastening, as well as the inability to use aluminum and copper conductors to combine.

Wago spring pads make it easy to create reliable contact between dissimilar conductors using a special lever clamp. Before using them at the junction with the cores, it will be necessary to remove the insulation. This method has practically no drawbacks, with the exception of the high cost of the terminals themselves.

Features of the installation of boxes in hazardous conditions and their designation on the diagrams

The following situations are considered to be dangerous conditions for the installation of junction boxes and the arrangement of internal connections:

- placement in bathrooms;

- wiring in the basement;

- arrangement of a junction box close to the ground or in conditions of high humidity (when connecting a submersible pump, for example);

- use for street lighting.

In this case, the conductors are connected only by soldering. It is allowed to twist and tin the resulting connection.

The cable entry into the box is sealed very carefully and is often filled with silicone. A trunk laid in the ground along with a distribution box is placed in a metal pipe, which excludes the destruction of the product by rodents. In addition, according to the requirements of the PUE, such lines are necessarily grounded. The considered security measures mainly relate to metal junction boxes in which direct contact with phase voltage threatens the user with an electric shock.

Designation on the scheme

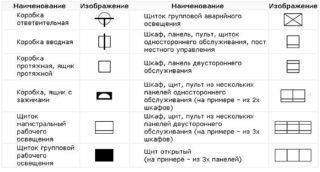

To mark boxes on electrical circuits, special icons are used, usually in the form of a circle or square with straight lines leading to them. According to their binding to graphic symbols, they are divided into the following categories:

- introduction boxes;

- branch products;

- feedthrough distributors;

- terminal (dead end) boxes.

Each of the elements indicated by this or that icon performs its function, which is manifested in the difference in their graphic displays (according to GOST 2.755-87).