Construction of houses and major repairs of apartments include the issue of conducting or replacing wiring. To make it safe and functional, you need to choose the right wire and cable. You should carefully familiarize yourself with the properties and characteristics of each proposed type of wire, as well as familiarize yourself with GOST standards and safety requirements in advance.

Why change the wiring

Wiring in the house is the most important system. Without it, not a single household appliance will work. However, it carries a danger. If materials are improperly selected or operating conditions are not observed, there is a risk of electric shock or fire.

There are two main reasons why people change the wiring in the house. First: any wiring has a limited life. Usually, replacement is required 15-20 years after the builders rent the apartment. If you do not make timely modernization, it will be dangerous to use electricity. Second: replacement is required in the case of adding new powerful electrical appliances.

It is not recommended to connect new electrical wiring to the old one, since the conductors may not match the characteristics and the material used.

Criterias of choice

There are a number of characteristics that you should pay attention to for the correct selection of wiring. The above requirements apply to the 220 V or 380 V electric network. Heating, computer and other conductors are selected taking into account other recommendations. The wiring for the apartment is determined by the properties of the conductors.

Mandatory Features:

- Core material. In home wiring, copper and aluminum conductors are used. Copper is a better, long-term and reliable material, therefore, according to the recommendations of the PUE, it should be used to create open and hidden wiring.

- Core design. There are single-core and multicore conductors. Stranded are highly flexible.

- Cross sectional area. Shows what load the conductor can withstand. For the home network, a 2.5 square mm copper cable is used. and 1.5 sq. mm. for lighting.

- Insulation thickness. This indicator is regulated by GOST. The wire must be reliably protected from external aggressive influences. For household cables, a thickness of 0.6 mm is recommended (at least 0.44 mm.).

- Shell thickness. Protects and fixes veins. For multicore cables, this indicator is 1.8 mm, for single-core cables - 1.4 mm.

- Conductor marking. A set of letters and numbers shows the characteristics of the product - core material, insulation, manufacturing plant, year of manufacture, number of cores, section.

- Coloring lived. It happens solid color or stripes. From the shades you can understand what this or that vein is responsible for (phase, zero, earth).

- Packaging. By standard, a bay or drum is used. Bays - for sales in chain stores, drums - for wholesale. Be sure to attach a tag with a description that indicates the brand, GOST, release date, length and number of segments, weight, drum number, conformity marks.

- Availability of necessary licenses and certificates. There should be two documents - a certificate of conformity and fire safety.

- General condition of products. Externally, the cable must not be damaged, otherwise it becomes unusable.

Studying these parameters will help when buying the best cable for wiring.

Types of cables for electrical wiring

There are different types of conductors that can be used for a home electrical network. They all have a marking by which it is possible to determine the material of cores and insulation, class of flexibility and cross-section. Color marking is also used to determine the purpose of the cores.

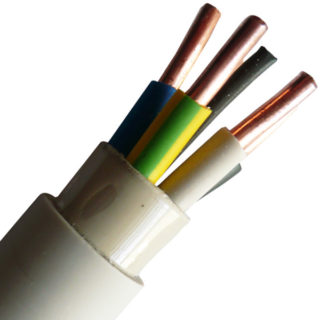

VVG

The cable for electrical wiring in VVG apartment is the most famous and used domestic cable in home electrical networks. It is possible to obtain the necessary current values and ensure appropriate safety with its help. The product is a copper wire with insulation and sheath made of PVC. It can work at normal and high humidity. Operating voltage should not exceed 660 V. This is a flexible unarmoured cable for wiring in the house. It contains up to 5 cores, depending on the modification, the cross-sectional area reaches 240 sq. Mm. The shape distinguish round, flat and triangular views.

The main modifications include VVGNG - non-combustible, VVGNG-ls - non-combustible with low smoke emission, VVGNG FR-LS - with additional fire protection from mica (used in rooms with increased fire hazard). For sockets, VVGNG 3x2.5 or VVGNG-LS 3x2.5 are usually used. For the switches, the same cables are selected, but with a cross section of 1.5 sq. Mm. Suitable for installation in all rooms, including the kitchen.

NYM cable

The European equivalent of VVG is NYM cable. It is manufactured both at Russian and foreign factories and complies with all accepted EU and GOST standards. There are two types of cables - single-wire with a cross section of 1.5-10 sq. Mm. and multiwire with a cross section over 16 sq. mm. Operating voltage does not exceed 660 V. PVC is used as a material for insulation.

To connect the sockets and the input, the NYM 3 × 2.5 model is used, for switches - NYM 3 × 1.5. When buying, it’s important not to confuse NYM with the cheaper NUM cable. It has reduced characteristics, so they can not be used to create home electrical wiring.

The advantages of NYM and VVG include:

- high quality workmanship that meets all the necessary requirements;

- ease of installation, ease of wiring;

- safety;

- fire resistance;

- self-extinguishing;

- low smoke during combustion;

- wide range for any finances.

Which cable is needed for wiring in a private house - BBH or NYM - each owner decides independently. These conductors are considered the most common.

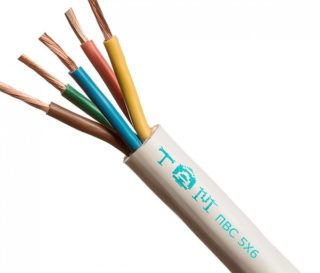

PVA wire

The connecting copper inner conductor is vinyl insulated. It can be bought to connect household appliances to the mains and create extension cords. Its design contains from 2 to 6 copper wires, the total cross section is from 0.75 sq. Mm. up to 10 sq. mm. The voltage limit is 380 V.

The main difficulty in working with the PVA wire is its multi-wire design. All ends must be tinned, which takes a lot of time and effort. Also, this factor leads to increased fire hazard. Due to the high heating, the insulation is destroyed, a short circuit may occur. Unlike cables, the wire cannot be laid in bundles. Each line will require a separate strobe.

ShVVP and PVVP wires

These are varieties of mounting cords with single or multi-wire cores made of copper. The main scope is the connection of household appliances. Shelf life is short, difficult to install due to the need for soldering. The insulation is flammable, so it is not suitable for home wiring.

Since 2007, the use of PUNP wire in electrical wiring has been prohibited. It is unsafe, the characteristics do not meet the standards.

Cable Management Equipment

Installation of electrical wiring requires a competent choice of conductors and the purchase of appropriate accessories for them.These are accessories, wiring devices and materials that will have to be consumed during work. In order to understand in advance how many devices you need to purchase, a diagram is drawn up with a wiring plan.

Additional devices that you will need to choose and buy are:

- protective equipment: circuit breakers and RCD;

- sockets;

- sockets, switches;

- cable channels;

- mounting boxes;

- corrugated tubes;

- visor

- insulation, clamps.

All products are selected for the appropriate load and individual characteristics of the apartment. You can close the wiring with plaster, since all cables are laid in the protective channels.