Modern electric range is characterized by high efficiency, functionality and accuracy of settings. However, the product consumes a lot of energy, which affects the features of its connection to the network. An incorrectly selected and connected outlet for a stove can cause fire, short circuit, and electric shock. To initially exclude the possibility of such situations, it is necessary to correctly design and connect a power point that is guaranteed to withstand such powerful consumers as an oven, oven and combined oven.

Distinctive features

Standard sockets for an electric stove are not suitable, because they are not designed for heavy loads. They need to be connected taking into account the maximum power consumption, which can reach 8 kW. Ordinary household points that are installed in the apartment are marked 16 A and can safely provide energy to consumers with power up to 3.5 kW.

The power outlet for the stove is distinguished by such features:

- Large thickness of conductive contacts. It can be 2-3 mm depending on the design load. Metal in power sockets and plugs for electric stoves has high strength, hardness and elasticity.

- The presence of grounding contact. It is necessary due to the fact that during operation there is a possibility of penetration of electricity into the housing. Since conventional clamping tendrils are not designed for high current strength, contact is made using a pin and a separate hole.

- Stronger body. Outlets for the stove are made of refractory polymer plastic, which does not lose strength when heated. The case is durable, resistant to shock and pressure.

Depending on the voltage coming through the cable, the socket may have 3 or 5 holes. The number is determined by the number of phases and the presence of grounding. A standard 380-volt outlet for a stove has 5 contacts, of which 3 are for connecting phases, and 2 are for zero and ground. But in apartments this option is almost never found, such decisions are made for the arrangement of industrial premises.

Wiring requirements

Most houses do not provide separate lines and sockets for electric stoves with increased power. The sockets installed in the kitchen are connected to one circuit, which is designed for a specific load. If you use a modern hob, then before the end of its work it is impossible to turn on such consumers as an electric kettle, oven and microwave. This is not very convenient if you need to cook a lot on several devices.

The houses built in the last century have aluminum wiring that can withstand a maximum load of up to 3.5 kW. Houses of modern series are equipped with cables with copper conductors 2.5 mm², rated for 4.6 kW. This is quite enough for an average power device. If there will be more consumers, it is better to change the wiring in order to avoid its overheating. It is advisable to purchase a cable with conductors 3.0 mm² (6.2 kW) or 3.5 mm² (8.0 kW). When making a choice, you need to focus on the peak value of electricity consumption.

The best solution is a cable with copper conductors. This metal is characterized by high conductivity, flexibility and elasticity.The problem with corrosion is solved easily and quickly by treating the contacts with tin.

Types of sockets for electric stoves

According to the purpose of the product, they are divided into rated voltage - 220 V and 380 V. The first type includes devices for operation in the kitchens of houses, cottages, cottages and hotels. The second type of product is used in restaurants, large canteens and in factories for the production of finished foods. Based on the purpose, the size, number of burners and power consumption varies.

By the number of connectors for a household 220 V network, stove sockets are as follows:

- phase, zero, earth (3);

- 3 phases, zero (4);

- 4 phases, zero, earth (5).

Devices differ in terms of operation. It depends on factors such as resistance to electrolytic corrosion, abrasion and bending. The main indicator is the number of on and off cycles.

In this area, the classification of quality is as follows:

- high - 100,000;

- average - 75,000;

- low - 50,000.

Based on the operating conditions and quality, the service life of the products varies between 10-25 years.

Installation of an electric socket can be done open or hidden. The choice depends on the installation location of the equipment and the option of laying the cable. The outdoor installation is universal, it is used on the street, balconies and in wooden buildings. The hidden method is used in residential buildings made of brick and reinforced concrete. In this case, before connecting the outlet for the stove, holes and strobes are made in the wall.

Resistance to external influences is important. Products have 6 degrees of protection against dust and 8 from water. For this, plugs, covers and blinds are used.

Socket selection according to the number of phases and grounding

The choice is determined by the configuration of the fork, which is equipped with the stove. Almost all manufacturers complete their products with cables rigidly fixed in the housing. The shape and type of forks is determined by the standards that apply in the importing country.

For a conventional furnace with power up to 6 kW, products with 3 connectors should be purchased - for phase, zero and earth. This scheme is designed for single-phase current, which is supplied to multi-storey buildings. If grounding is not provided in the building, you can purchase a conventional 2-socket power outlet.

Three-phase devices are used for powerful electrical equipment consuming 6-12 kW. Here, the phase dispersion scheme for 3 contacts that are available on the device mounting block is used. Grounding is mandatory; cook's safety issues depend on it.

Design Tips

When choosing a product, you must pay attention to the availability and quality of parts that determine its reliability, durability and safety.

The quality of the product is affected by such nuances:

- Price. Good things can not be cheap (at least 1000 rubles).

- The location of the nodes. It should be compact and ergonomic.

- The nominal value of the device. Must have a peak load margin.

- Type of installation - hidden or open. Here the choice is made between ease of installation and practicality.

- The presence of grounding. This function will protect the cook from electric shock in the event of an emergency.

- Appearance. It matters if the outlet is in plain sight.

It is necessary to provide for the possibility of communication between devices of different configurations. In some cases, it is allowed to use a certified adapter from one plug to another. If there is a need to install a dual source, you should use a splitter with outputs for the desired technical request. In one socket, you can connect a single-phase plug 32a for an electric stove, and in the second insert a regular plug from the dishwasher.

Shield preparation

A properly designed and assembled shield will allow you to properly distribute energy between consumers and completely eliminate the risk of a short circuit. If you even have basic knowledge about the nature of electricity, you can do it yourself.

First you need to calculate the number of household appliances and their total power. Proceeding from this, an input automaton, designed for 32 A or 40 A, is selected. Then a drawing is drawn up in which the wiring and jacks are drawn. The power line for the stove is done separately.

In multi-storey buildings, only open type shields can be installed. It is better to place them in places that are inaccessible to children and pets. Inside the box are the input and intermediate bags, mounting rails, RCDs, phase, protective and neutral conductors.

Priority should be given to boxes made of heat-resistant refractory plastic. This will prevent electric shock when one of the wires is released and it touches the housing. Mounting to the wall should be as rigid as possible, eliminating the accidental tearing of the box.

Power outlet

Connection is made in accordance with the electrical circuit of the device and the type of voltage supplied to the house. Before connecting, the ends of the wires must be cleaned, treated with acid and soldered.

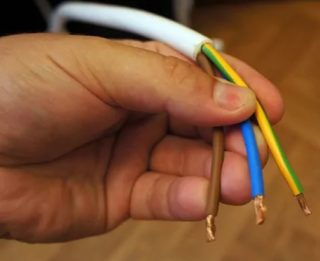

If there is a single-phase current in the network, the wires are connected in accordance with the marking of the contacts or their color designation. The yellow-green vein leads to the ground, red to phase, and blue to zero.

In a similar way, a two-phase device is communicated.

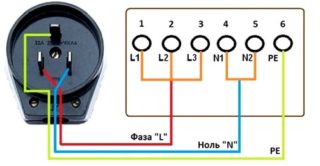

Wiring diagram:

- L1 - phase A (brown);

- L2 - phase B (white);

- N is zero (blue);

- PE - ground (yellow-green).

Three-phase sockets are connected to the network as follows:

- L1 - phase A (brown);

- L2 - phase B (white);

- L3 - phase C (brown with a white stripe);

- N is zero (blue);

- PE - ground (yellow-green).

After fastening the wires, you need to check the reliability of the connection by slightly pulling them back.

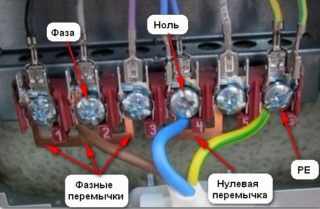

Connecting contacts to the stove

When purchasing imported products, you may encounter a lack of a power cable coming from the stove. Similar stories happen when buying used equipment. Since the boards in the furnaces are standard and designed for all types of connections, you should start with the selection of sockets and plugs that correspond to the wiring in the apartment. After this, it remains only to attach the cores to the slab.

Depending on the number of cores, zero, phase and ground are connected to the board. Before this, the identification of the polarity of the jack is carried out. By default, current is supplied to the left connector, and the right is given to zero. The middle is ground. If there is no land in the network, it makes no sense to attach the yellow-green wire.

If there are 5 or 6 contacts on the board, the connection is performed as follows:

- L1 - phase A (brown);

- L2 - phase B (white);

- L3 - phase C (brown with a white stripe);

- N (1 or 2) - zero (blue);

- PE - ground (yellow-green).

Some manufacturers place jumpers between the contacts. If they are not removed, a short circuit will occur when the device is turned on.

How to transfer the outlet to another location

In accordance with SNiP, it is forbidden to use household extension cords to connect powerful equipment. This can lead to overheating, fire, and short circuiting.

You can transfer a point by installing it in a new socket using the old channel and new strobes for wires.

The voltage is supplied in the following ways:

- special extension cord;

- laying a new line;

- cable extension when the wires are connected by soldering, welding, crimping or terminals.

Each option has its pros and cons. A decision is made in each case in relation to the circumstances.

Safety regulations

When installing and operating power outlets, the following safety measures must be observed:

When installing and operating power outlets, the following safety measures must be observed:

- Connect with a completely de-energized line at the input bag.

- In the work, use only quality material from trusted manufacturers.

- Position nests no closer than 50 cm from kitchen sinks, water, gas and sewer pipes.

- Observe caution when connecting wires, check that the connection is correct before applying voltage.

Compliance with these rules will allow for competent installation, using the stove will not cause problems for many years.